Propenoic acid resin film for wooden decoration and use for wooden decorative body

A technology of acrylic resin and acrylic resin, which is applied in the direction of wood layered products, chemical instruments and methods, layered products, etc., and can solve problems such as cost increase and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

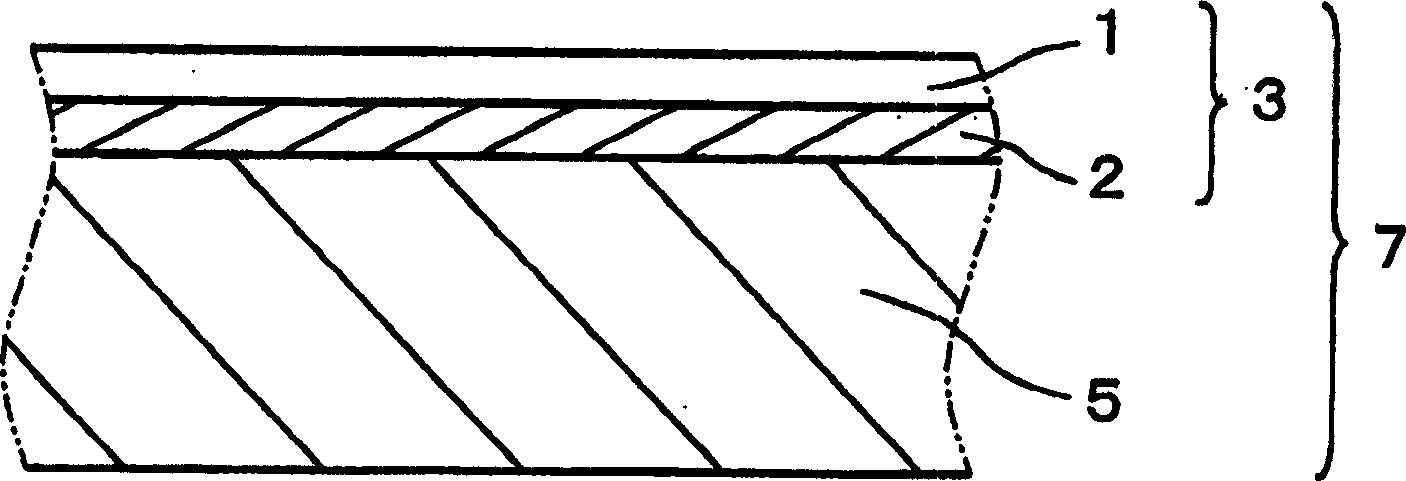

Image

Examples

Embodiment 1

[0050] As the methacrylic resin, resin pellets (glass transition temperature: 103° C.) obtained by a bulk polymerization method comprising a monomer composition of 97.8% of methyl methacrylate and 2.2% of methyl acrylate were used. As rubber particles, it can be produced according to the standard of Example 3 in Japanese Patent Publication No. 55-27576 (=USP 3793402), and a spherical three-layer structure is formed from the following three polymers, that is, the innermost layer is made of methyl methacrylate Cross-linked polymer polymerized with a small amount of allyl methacrylate, the middle layer is a soft elastic copolymer polymerized with butyl acrylate as the main component, styrene and a small amount of allyl methacrylate, and the outermost layer The layer is a rigid polymer polymerized by using a small amount of ethyl acrylate in methyl methacrylate, and the average particle diameter of the elastic copolymer layer used is 250 nm.

[0051] 70 parts of methacrylic resin ...

Embodiment 2

[0054] The composition of the rubber particles is basically the same as in Example 1, but the polymerization conditions are changed to a spherical three-layer structure with an average particle diameter of 140 nm. Others are the same as in Example 1, and a 250 μm thick acrylic resin film is made, and then the resin is used The film was processed in the same manner as in Example 1 to make a wooden decorative film and a wooden decorative molded body.

Embodiment 3

[0084] 1-Methoxy Dilute the polyfunctional urethane acrylate oligomer to a concentration of 25% and use it as a hard coating agent. A 25% concentration of hard coating agent was applied to the surface of the acrylic resin film of the wood decorative film obtained in Example 1 with a brush. After drying in an oven at 40°C for 10 minutes, use 400mJ / cm 2 intensity of ultraviolet light, and harden. According to JIS K5400, the obtained hard coating layer was measured for the pencil scratch value, and the pencil hardness was raised to 3H.

[0085] The acrylic resin film of the present invention is laminated with a wood film to form a wood decorative film, and the wood grain pattern of the wood film can be clearly observed. If the wood decorative film is arranged on the outermost surface of the acrylic tree film, a thermoplastic resin is pasted on one side of the wood film, and formed as a whole to form a wooden decorative molded body, the weather resistance, damage resistance, ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com