Paper sack

A paper bag and bag technology, applied in the field of paper bags with a new structure, can solve problems such as insufficient weight, low strength, and bag rupture, and achieve the effects of preventing sliding, ensuring safety, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

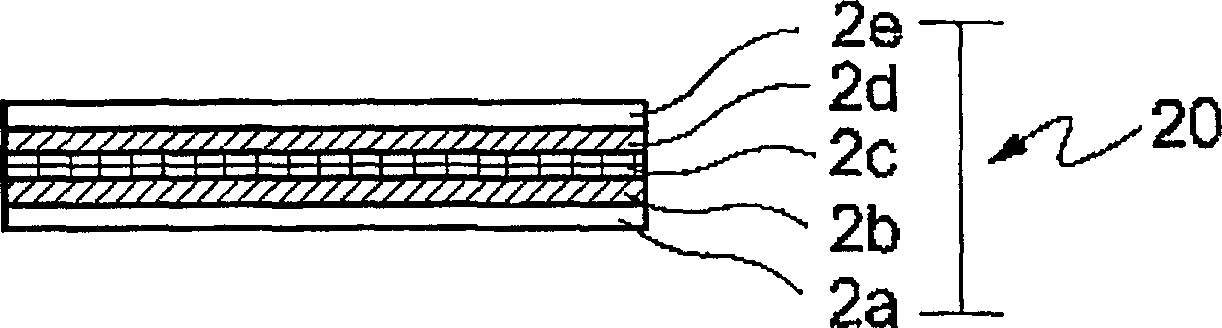

[0062] figure 2 The laminated structure of the double core paper according to the present invention is described, showing the structure of the DMP 20, that is, a core paper layer 2a, an adhesive layer 2b, a synthetic resin wire layer 2c, an adhesive layer 2d and a core paper layer 2e-a Build up layer by layer. The components of the adhesive were 70 wt% water-soluble acryl emulsion, 29 wt% EVA and 1 wt% softener.

Embodiment 2

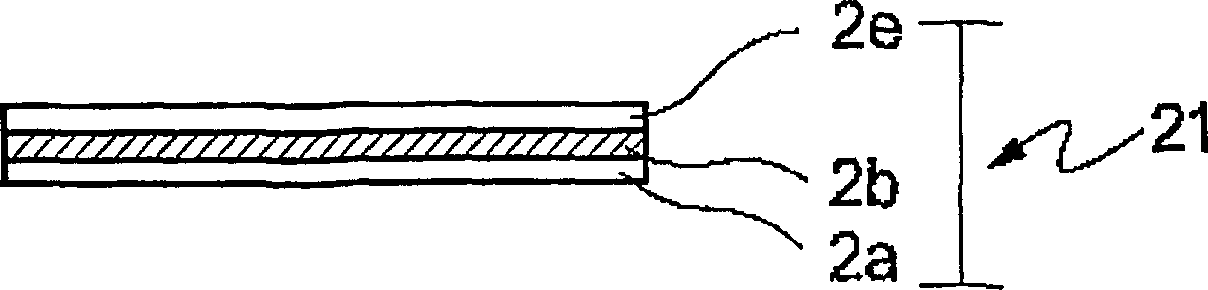

[0064] image 3 Illustrating another structure of the double core paper according to the present invention, the structure of the DMP is shown, that is, the core paper layer 2a, the adhesive layer 2b and the core paper layer 2e are stacked one on top of the other. The composition of the adhesive is the same as in Example 1.

Embodiment 3

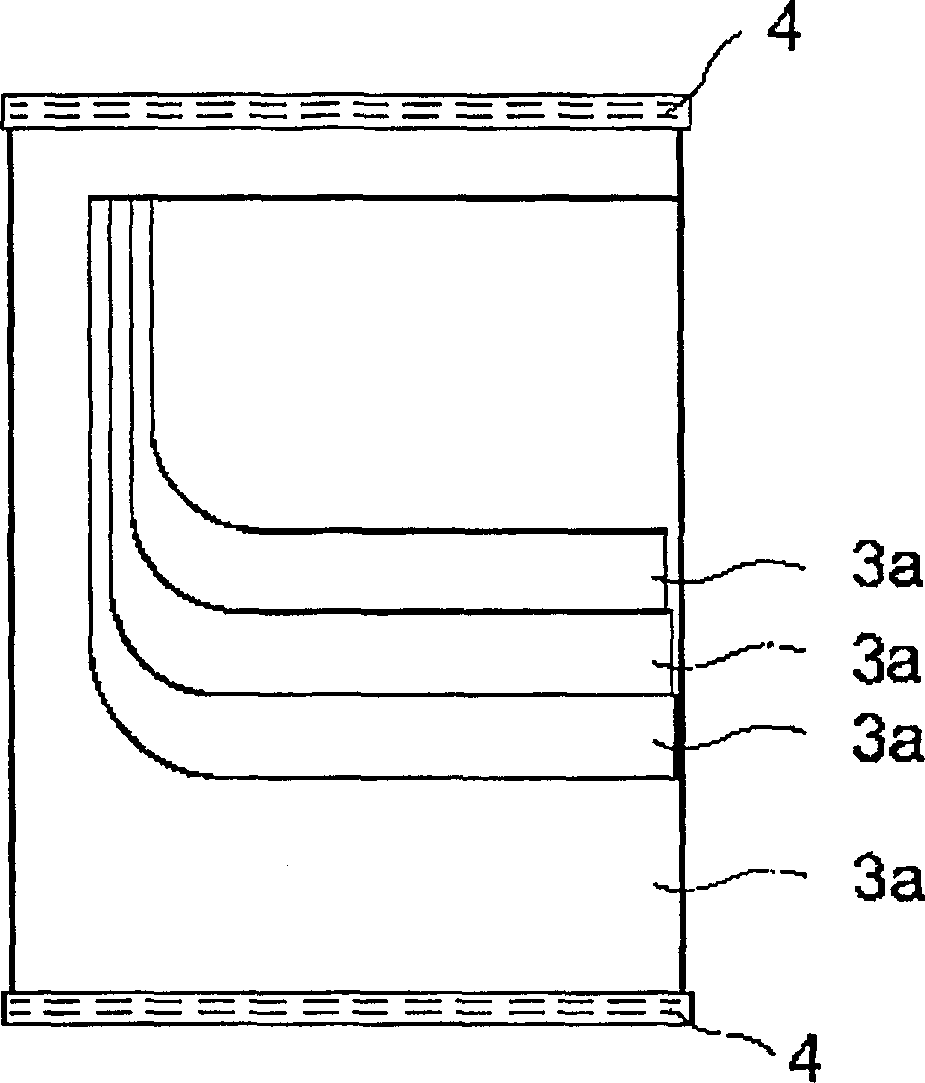

[0066] Figure 4 and Figure 5 An example of a double-layered paper bag according to the present invention is illustrated, which consists of a sheet of plain kraft paper used as the outer layer 3a, and a double core paper used as the middle and inner layer 20 according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com