Nanometer magnetic sensitive speed sensor

A speed sensor and nano-magnetic technology, applied in the field of automobile wheel speed sensing and detection, can solve the problems of poor sensor temperature stability, leakage signal, open magnetic circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

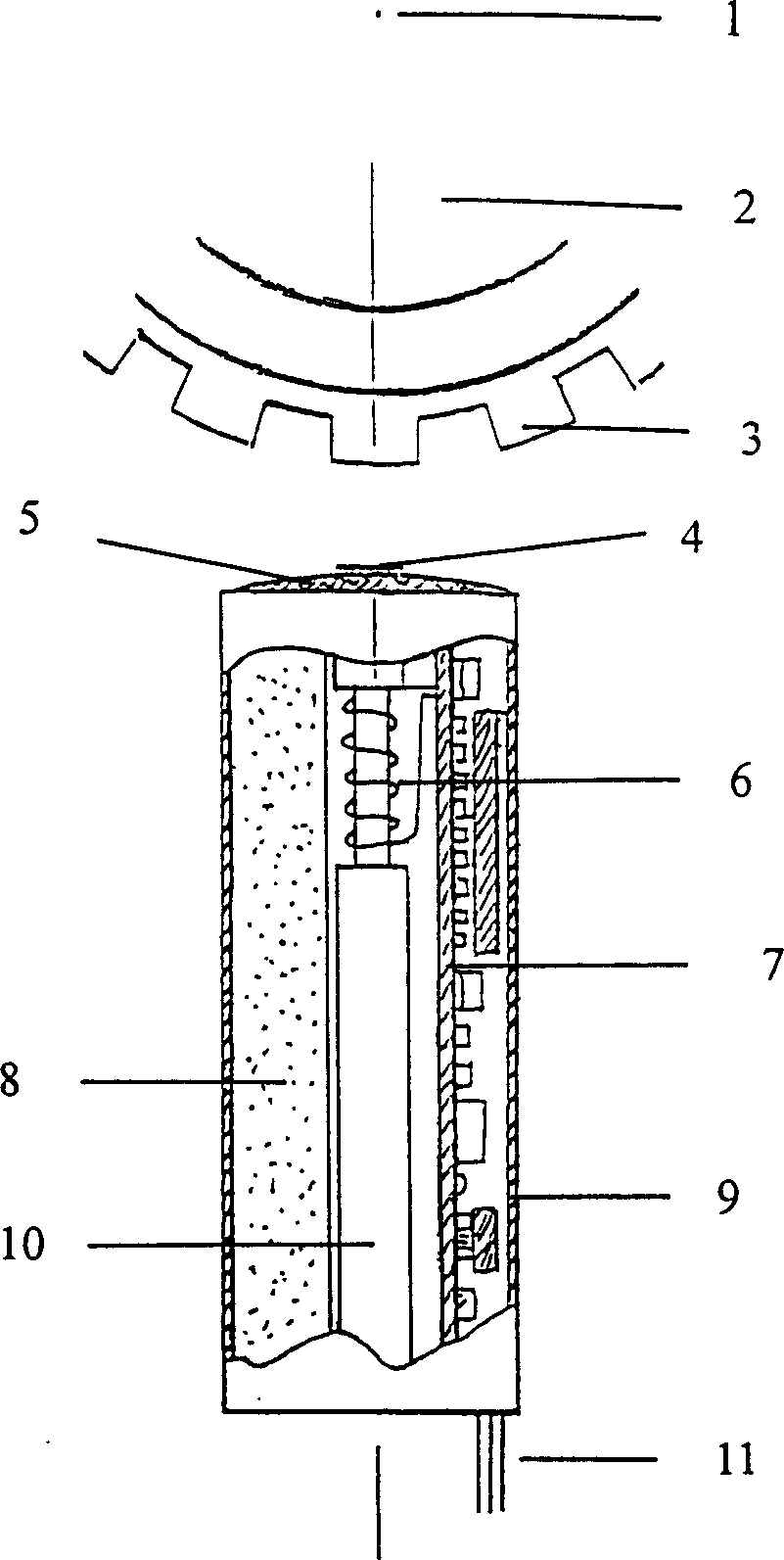

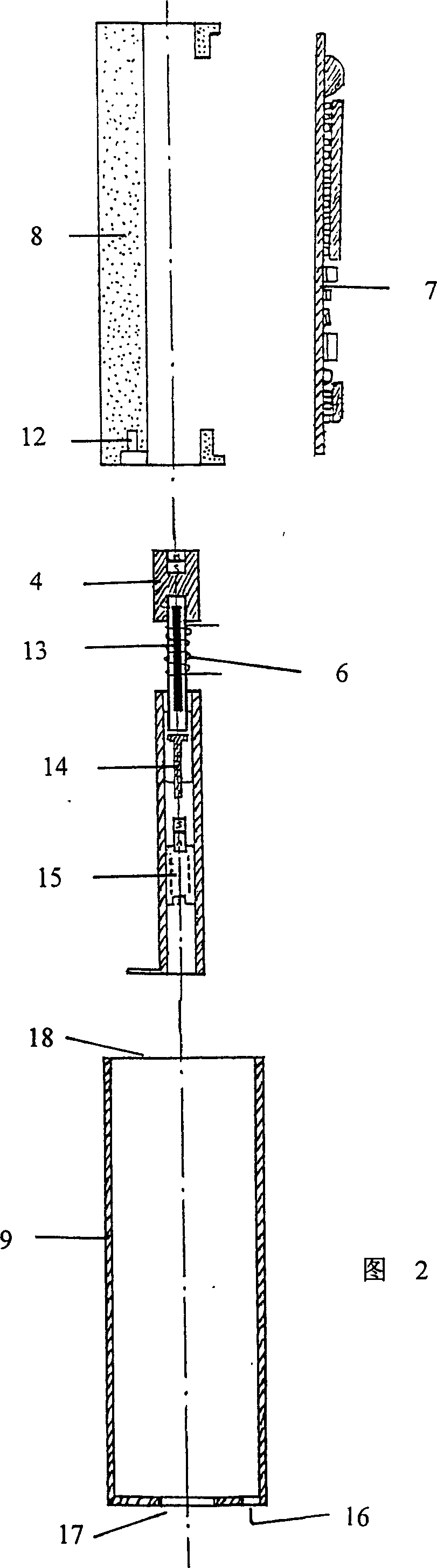

[0016] The magnetic head adopts φ2×2mm cylindrical permanent magnet.

[0017] The adjustable bias magnet adopts permanent magnet ferrite with φ4×6mm band.

[0018] The coil tube of the coil 6 is a φ2.5×12mm sealed ceramic tube with covers at both ends, and the coil 6 uses a φ0.04mm high-performance enameled wire, which is wound 120 turns outside the above-mentioned ceramic tube.

[0019] The iron-based nano-magnetic strip 13 is made of iron-based nano-microcrystalline FeCuNbSiB material, with a size of 12×1×0.025 mm.

[0020] The magnetically permeable core 14 is an iron core made of soft iron, and its size is φ1×8mm.

[0021] The shell 9 is a ferromagnetic shell made of soft iron.

[0022] The skeleton 8 is a special-shaped member made of polytetrafluoroethylene.

[0023] The seal 5 is a cover made of epoxy, which plays a role of fixing and protecting between the magnetic head 4 , the frame 8 and the shell 9 .

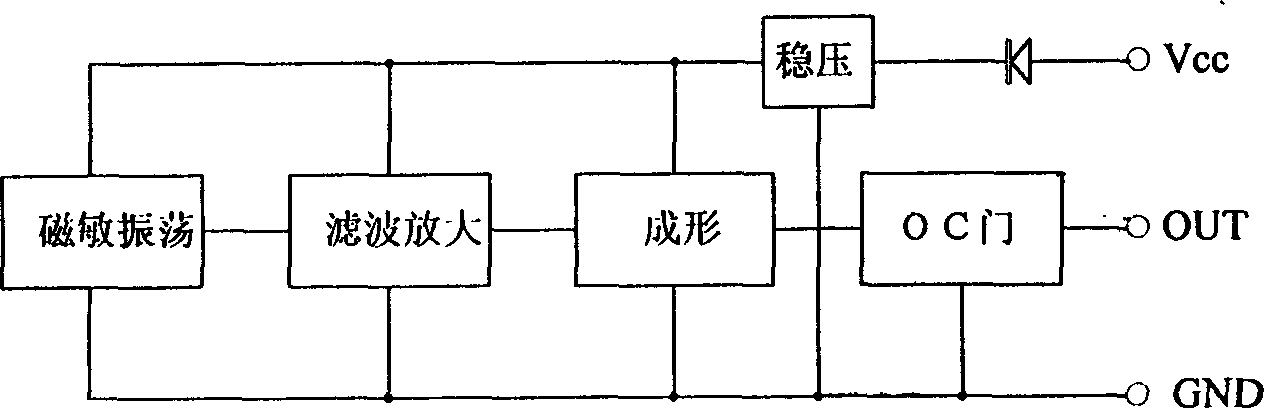

[0024] The block diagram of the circuit structure of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com