Method for forming MTJ of magnetic RAM

A random access memory, magnetic tunnel junction technology, applied in static memory, digital memory information, information storage, etc., can solve problems such as reduced productivity, discontinuous edge level difference, difficult MTJ layer, etc., to avoid corrosion, good profile , the effect of avoiding thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

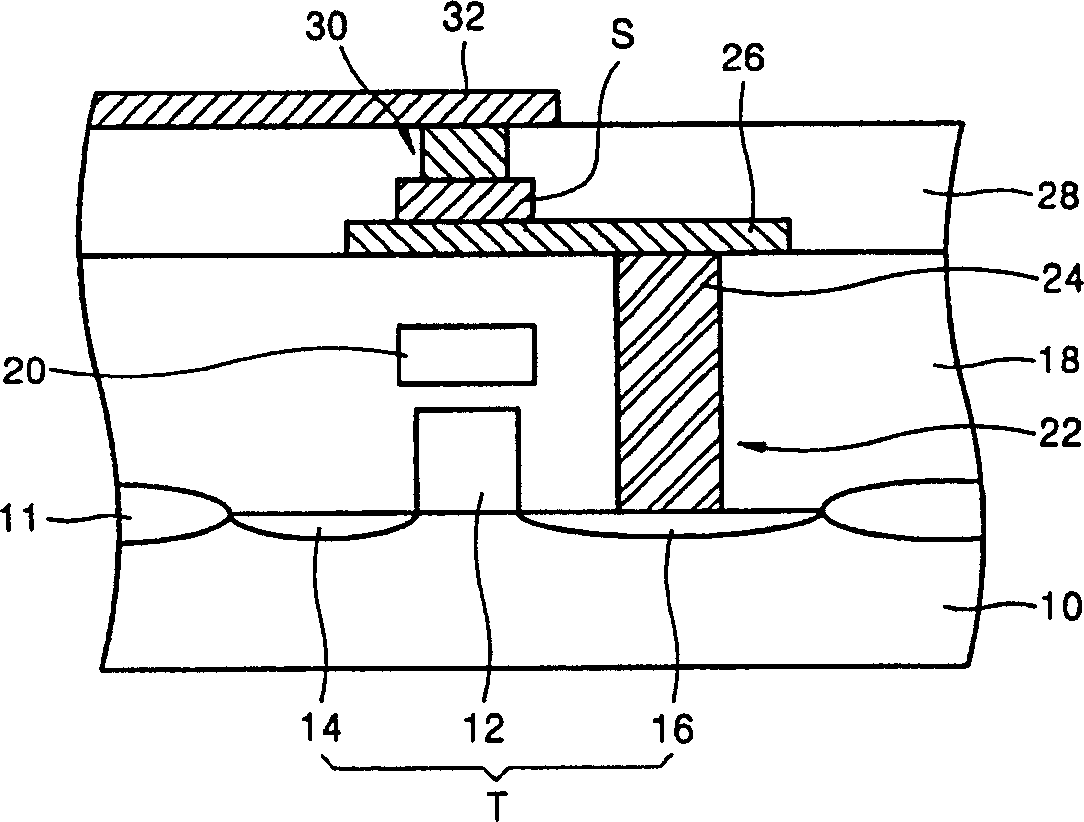

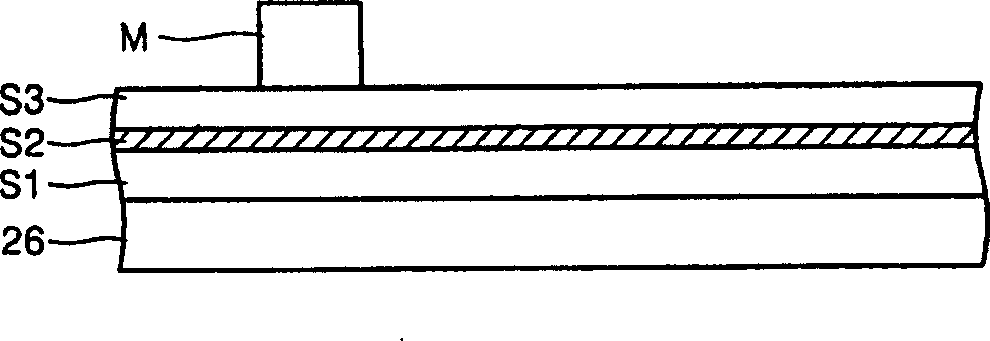

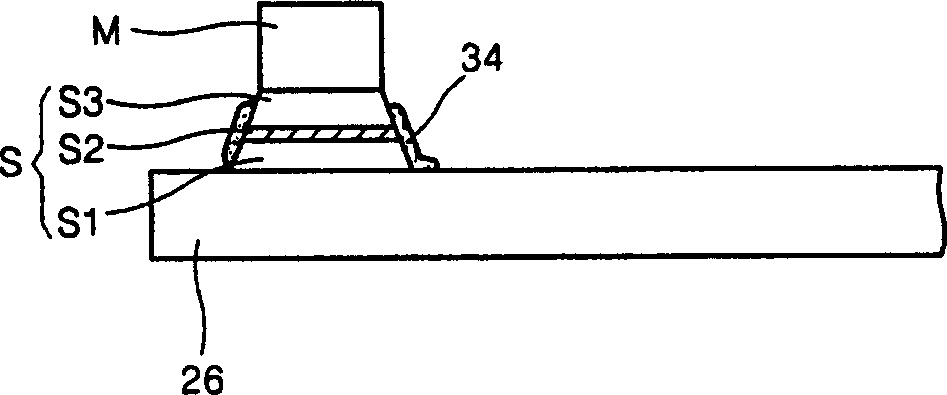

[0039] A method of forming a magnetic tunnel junction (MTJ) layer of a magnetic random access memory (MRAM) according to a preferred embodiment of the present invention will be further described below with reference to the accompanying drawings. In the drawings, the thickness of layers and regions are exaggerated for clarity.

[0040] like Figure 4 The shown method for forming the MTJ layer of the MRAM includes: forming a transistor on a substrate in step S10, and then sequentially forming a data line and an MTJ layer above the transistor by using a predetermined plasma etching process in step S20, so that the MTJ layer A transistor may be connected, and a bit line connected to the MTJ layer is formed in step S30.

[0041] refer to Figure 5 , step S10 includes: defining an active region and a field region on the substrate in step S10a, forming a field oxide layer for device insulation in the field region in step S10b, forming a gate stack including a gate in step S10c A sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com