New typs powder for keeping foodstaff fresh

A hydrosulfite, a new type of technology, applied in dyeing, textile and papermaking, etc., can solve the problems of fast decomposition, easy heat generation, high pollution components, and achieve the effects of slow decomposition, good stability and safe storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take 300g of thiourea dioxide powder and 700g of sodium chloride powder, mix them, and make hydrosulfite through uniform stirring.

Embodiment 2

[0015] Get 250g of thiourea dioxide powder and 750g of sodium chloride powder, mix them, and make hydrosulfite through uniform stirring.

Embodiment 3

[0017] Get 350g of thiourea dioxide powder and 650g of sodium chloride powder and mix them, and make hydrosulfite through uniform stirring.

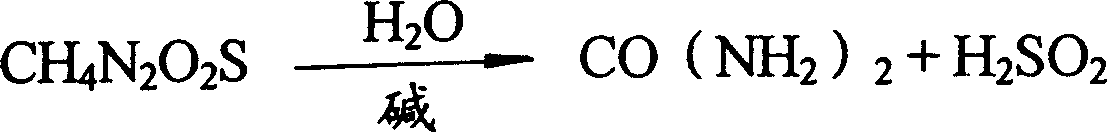

[0018] The principle of the strong reduction method of thiourea dioxide is as follows:

[0019]

[0020] Thiourea dioxide decomposes into urea and strongly reducing hyposulfuric acid in alkaline solution.

[0021] The sodium chloride in the novel sodium hydrosulfite of the present invention can be used as a dyeing accelerator and a stabilizer to enhance the stability of the hydrosulfite and facilitate the storage of the hydrosulfite.

[0022] The novel hydrosulfite of the present invention is a white crystalline powder, tasteless and easily soluble in water.

[0023] The invention can be used for denim dyeing, bleaching of cotton, wool and chemical fiber, reducing agent of vat dyes and sulfur dyes, printing of disperse dyes, stripping of textiles, and reprocessing or removing floating colors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com