Electrode for electromechanical battery, and electrochemical battery

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve the problems of battery performance degradation, cycle life reduction, etc., and achieve the effect of improving cycle life performance and high-speed charging/discharging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

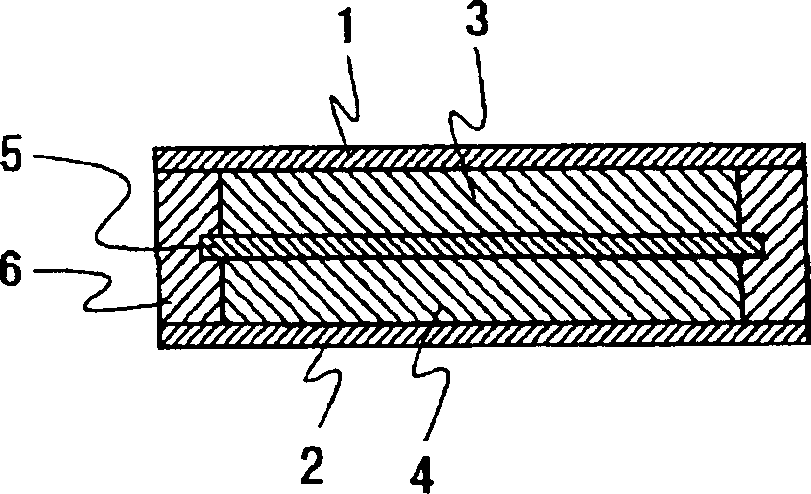

preparation example Construction

[0075] Although here the anion exchange resin is mixed with other electrode materials before coating, it is also possible to prepare an electrode by forming an anion exchange resin layer on the surface of the electrode. According to this process, the electrode preparation method includes the steps of: molding the mixture of electrode materials containing electrode active materials, conductive auxiliary materials, binders, etc., coating the slurry containing dispersed anion exchange resins on the moldings, and drying the coating. Cloth slurry; or a method comprising the steps of: putting a dry powdery electrode material mixture in a mold, adding a dry anion exchange resin on the surface of the mixture, and forming it by batch pressure molding.

[0076] The amount of the anion exchange resin relative to the electrode active material can preferably be appropriately selected within the above-mentioned limit range. For the electrode formed by dispersing the anion exchange resin in ...

Embodiment 1

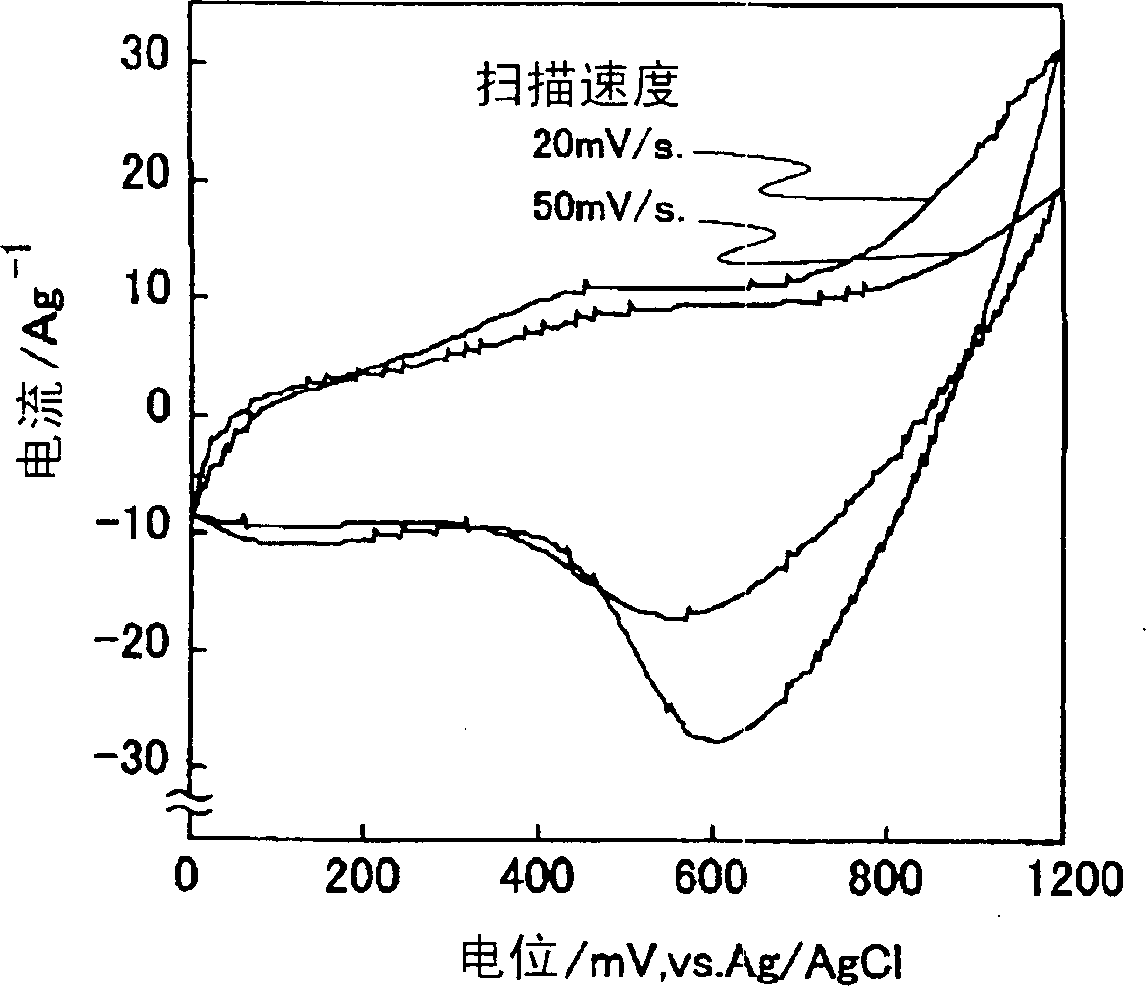

[0118] 5-cyanindole trimer is used as the cathode active material, carbon fiber is used as the conductive auxiliary material, and PVDF (average molecular weight: 1100) is used as the binder, weighed sequentially with a weight ratio of 69 / 23 / 8, and the weight ratio of the cathode active material is 0.3 % by weight added to the anion exchange resin. The mixture is stirred and mixed with a mixer. The anion exchange resin is a fiber with a length of 3 mm obtained by cutting a fiber made of polyvinyl alcohol, which has trimethylammonium as an anion exchange group, wherein the ion type exchanged is -OH type, and its main axis 60 μm (Nitivy Co. Ltd., IEFSA (OH)).

[0119] Then, 10 mg of the mixed powder was weighed into 1 mL of DMF. The mixture was stirred at room temperature for 5 minutes to become a uniformly dispersed slurry. This slurry was applied to a current collector by screen printing and dried to form a cathode having a thickness of 100 µm, which was cut into a predeterm...

Embodiment 2

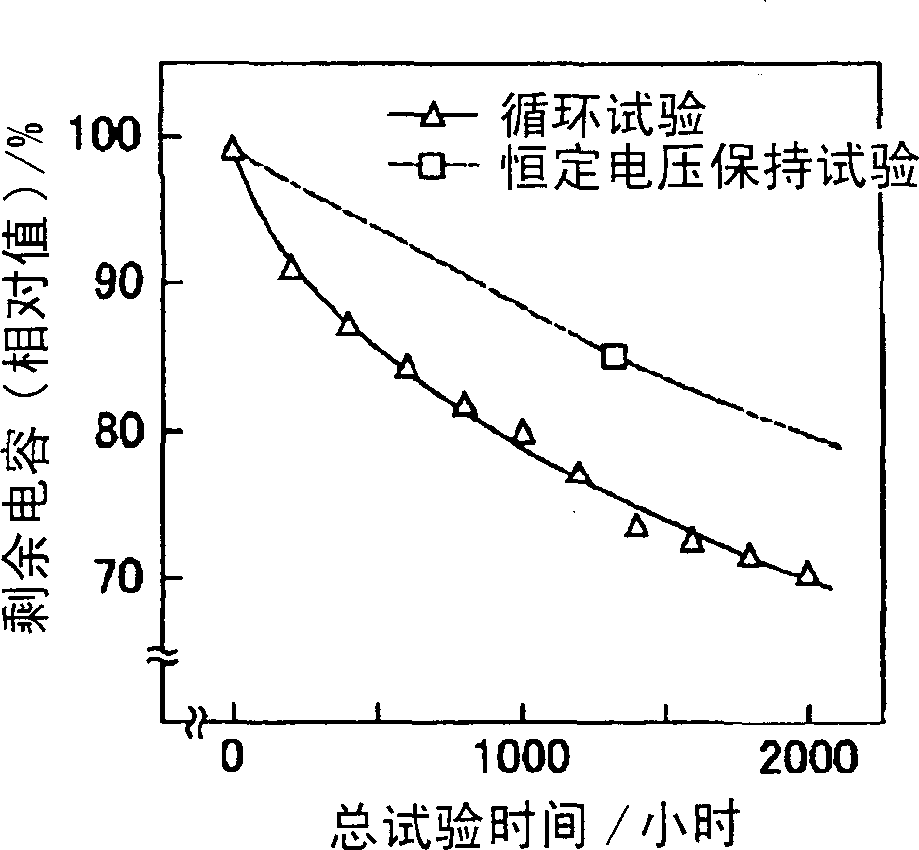

[0124] The cathode and anode material mixtures were prepared as described in Example 1. Electrochemical cells were then prepared as described in Example 1, except that each electrode was thermocompressed, and its high-temperature cycle performance was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com