Method for making biologic composite materials of nanometer hydroxyapatite/polyamide series for medical use

A technology of nano-hydroxyapatite and composite materials, which is applied in medical science and prostheses, and can solve problems such as low output, expensive solvents, and difficult process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

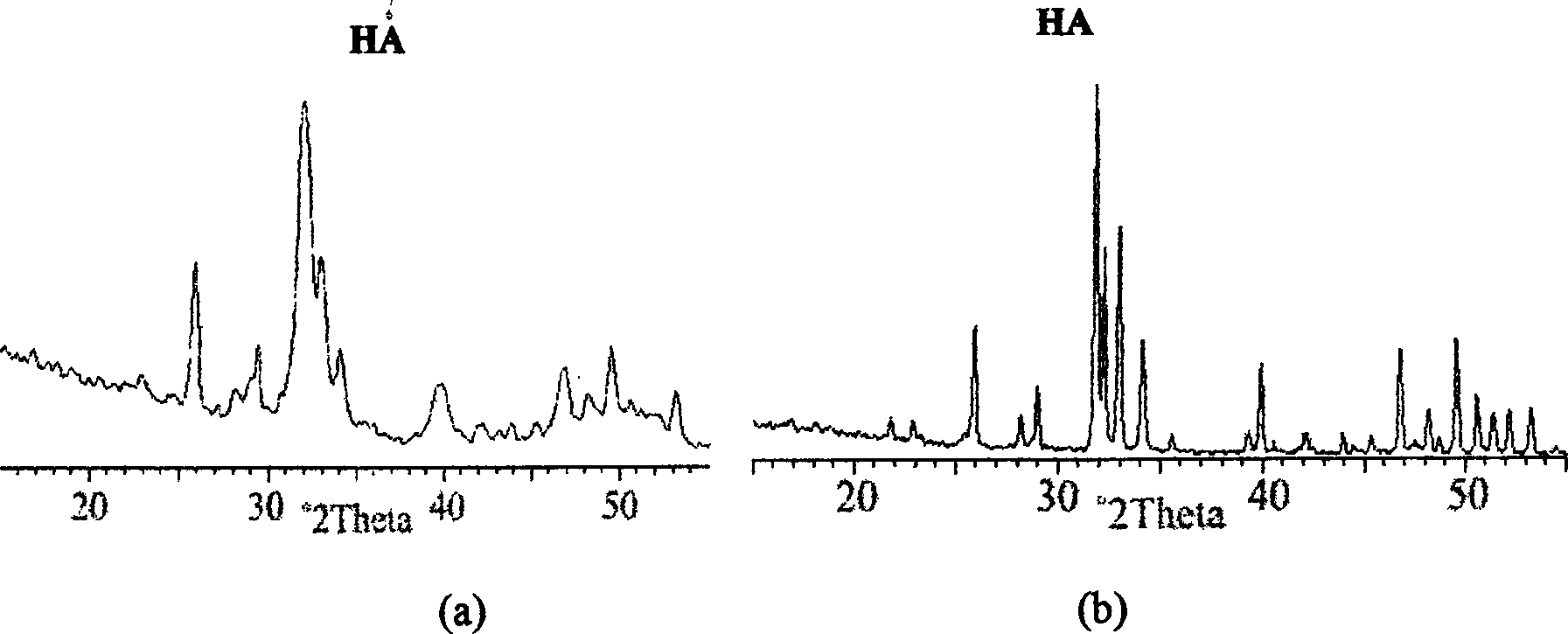

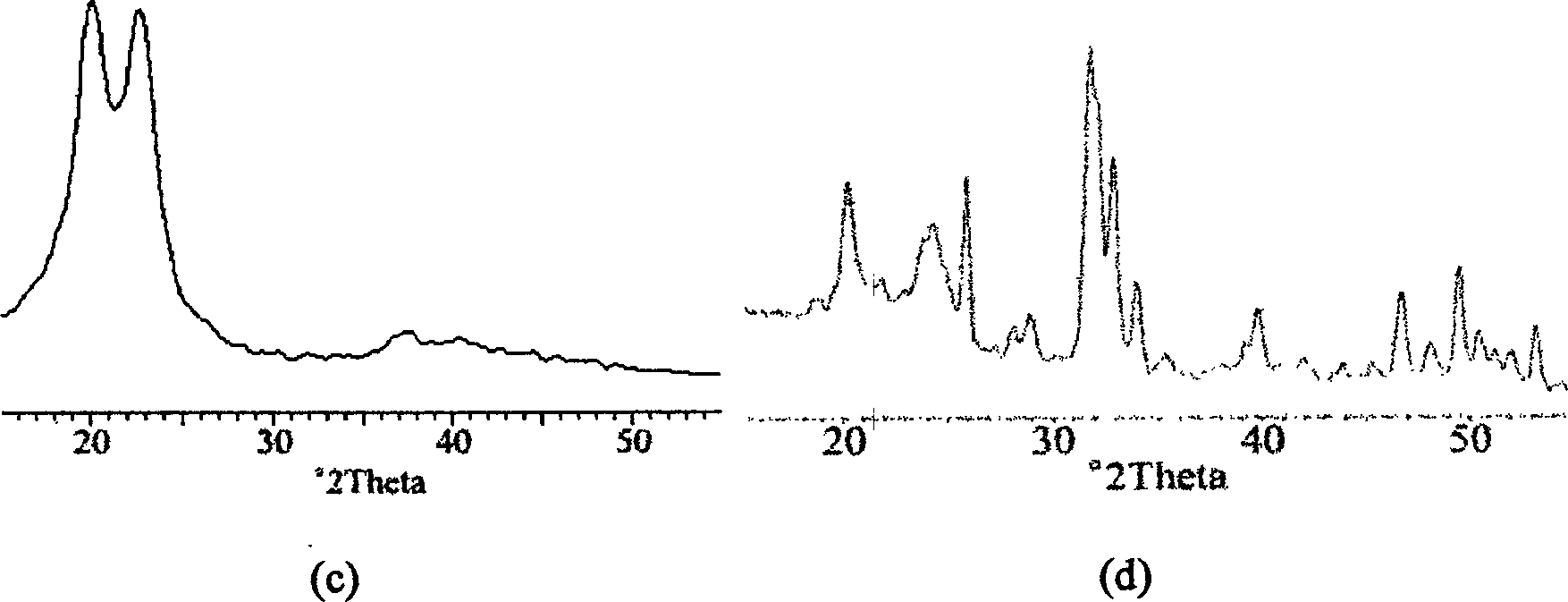

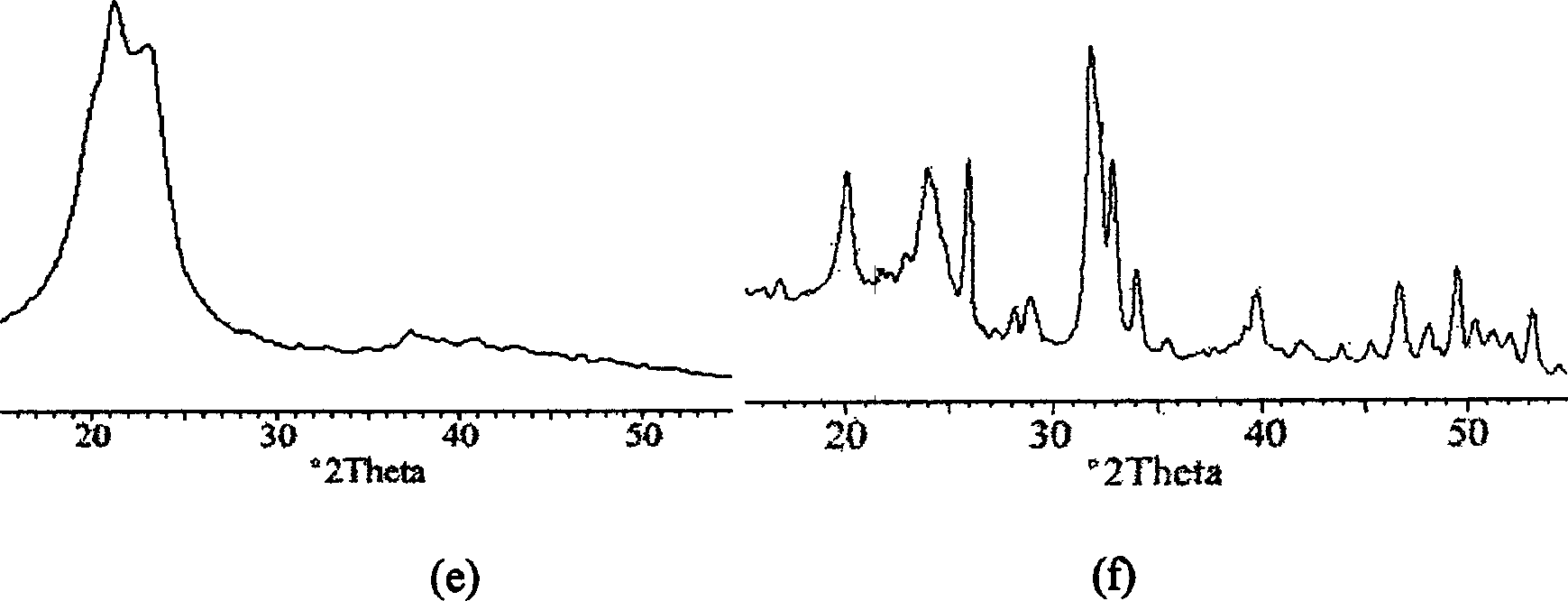

Image

Examples

Embodiment 1

[0022]Dissolve 15 g of calcium chloride in 150 ml of methanol solvent, add 15 g of polyamide 66, and dissolve at 55°C under stirring. The nano-hydroxyapatite slurry is prepared by the wet synthesis and hydrothermal treatment method reported in the above-mentioned "J. Mater. Sci.: Mater. in Med." 5 (1994): 252-255 (water content 66%), Weigh 29.4 grams of the slurry, mix 1.5 grams of polyethylene glycol 6000 and 50 ml of methanol into the slurry and stir well. The aqueous methanol slurry of nano-hydroxyapatite was slowly added to the calcium chloride / methanol solution of polyamide 66, and the mixture was kept fully stirred at 55°C for 2 hours to prepare nano-hydroxyapatite / polyamide 66 (weight The ratio is 4 / 6) composite materials. All reagents used are analytical grade (AR). The product mixture after the reaction is precipitated in deionized water, and then washed with hot deionized water for 6 times, anhydrous ethanol for 2 times, dried at 100° C., and ground for use.

Embodiment 2

[0024] The polyamide material was changed to polyamide 6, and the nano-hydroxyapatite slurry and other operating methods and conditions were the same as in Example 1, to prepare a nano-hydroxyapatite / polyamide 6 (weight ratio of 4 / 6) composite material.

Embodiment 3

[0026] Dissolve 25 g of calcium chloride in 150 ml of methanol solvent, add 30 g of polyamide 66, and dissolve at 50°C under stirring. The preparation method of the nano-hydroxyapatite slurry is the same as in Example 1. Weigh 22.05 grams of the slurry (with a water content of 66%), mix 1.2 grams of polyethylene glycol 6000 and 40 ml of methanol into the slurry and stir evenly. The calcium chloride / methanol solution of polyamide 66 was slowly added to the aqueous methanol slurry of nano-hydroxyapatite, and the temperature was maintained at 60 ℃ and fully stirred for 1 hour to prepare nano-hydroxyapatite / polyamide 66 ( 20 / 80) Composite materials. All reagents used are analytical grade (AR).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com