Method for preparing LiFeP04 material by microwave method

A microwave method and raw material technology, applied in chemical instruments and methods, electrode manufacturing, inorganic chemistry, etc., can solve the problems of incomplete reduction, large powder particle size, poor high-rate discharge performance, etc., to prevent the growth of grains , short synthesis time, rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

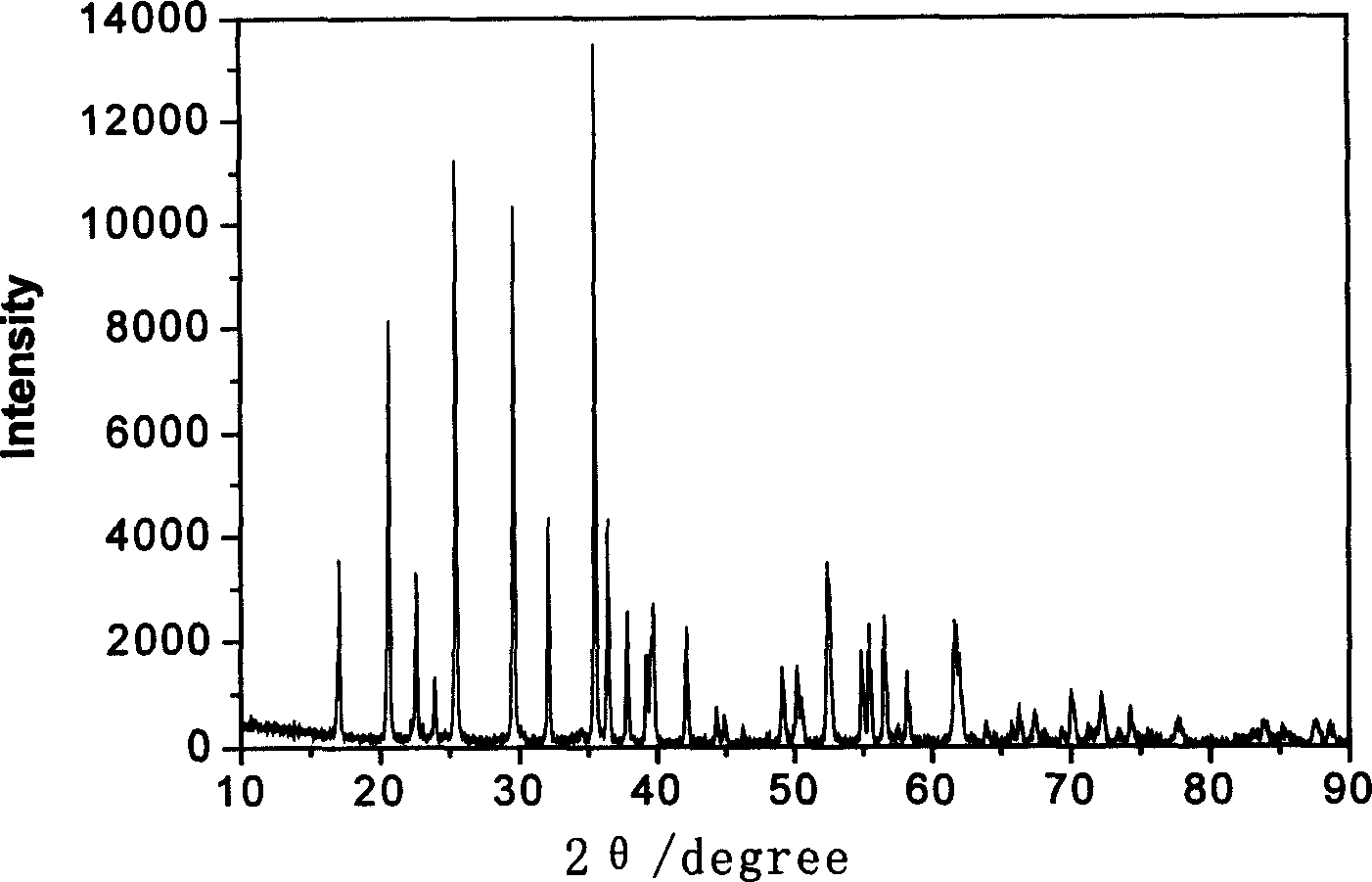

[0017] The dried material was pressed into tablets, put into an alumina crucible equipped with activated carbon and insulation materials, and then the crucible was placed in a household microwave oven (frequency 2.45 GHz), the power was adjusted to low fire level 3, and the microwave was irradiated for 9 minutes. The phase analysis results of the obtained sample are shown in figure 1 . It can be seen from the XRD pattern that the synthesized product is olivine-type LiFePO 4 , no impurity phase.

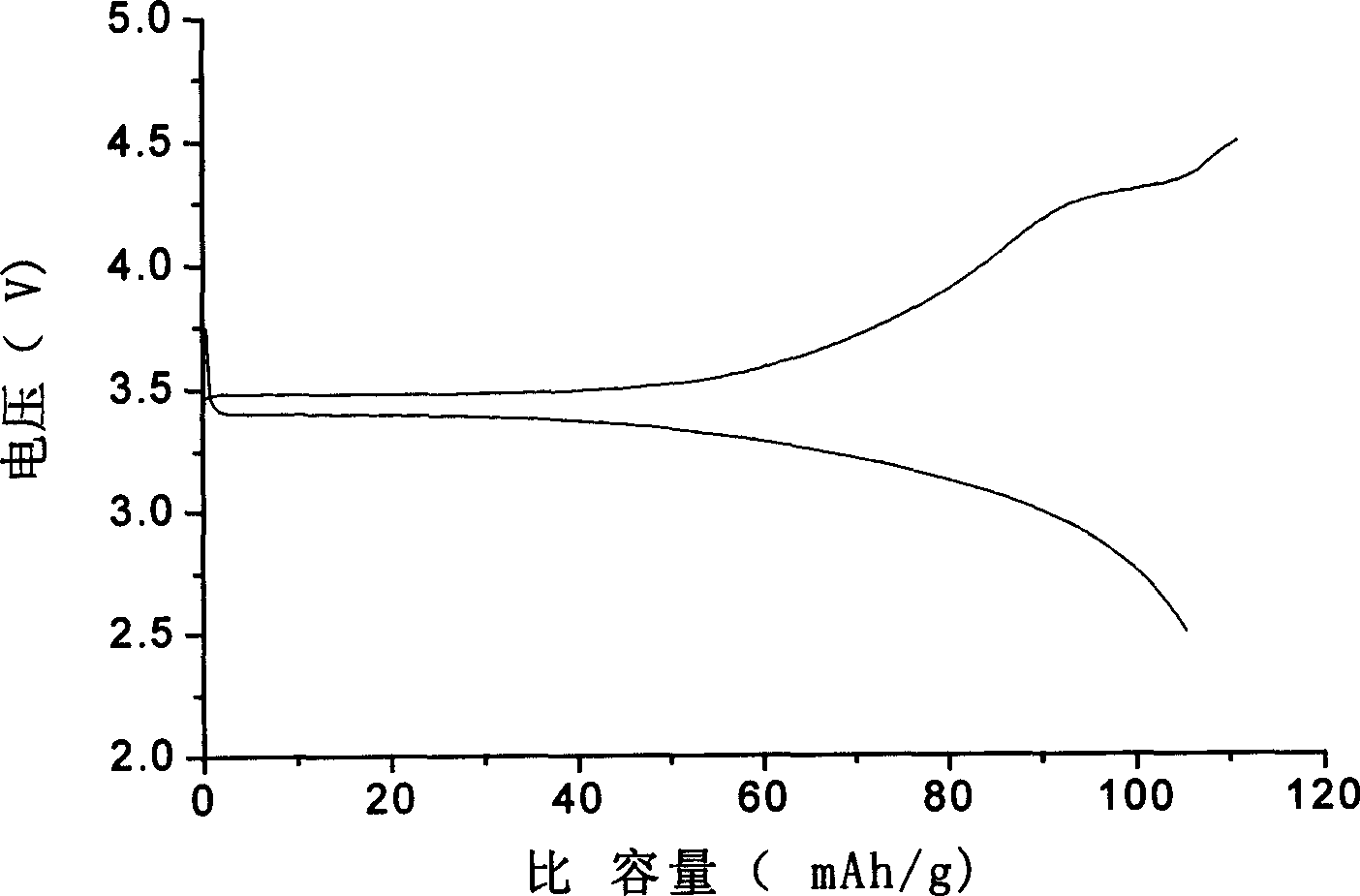

[0018] The synthetic material is added with a conductive agent and a binder (20% and 5% respectively) is bonded and pressed to form a film, and a test battery is formed with metal lithium, and a constant current charge and discharge experiment is carried out. The charge and discharge current is 10mA / g, and the charge and discharge voltage range Control between 2.0-4.5V. figure 2 The 12th charge and discharge curve is given, and the specific capacity can reach more than 100mAh / g. ...

example 2

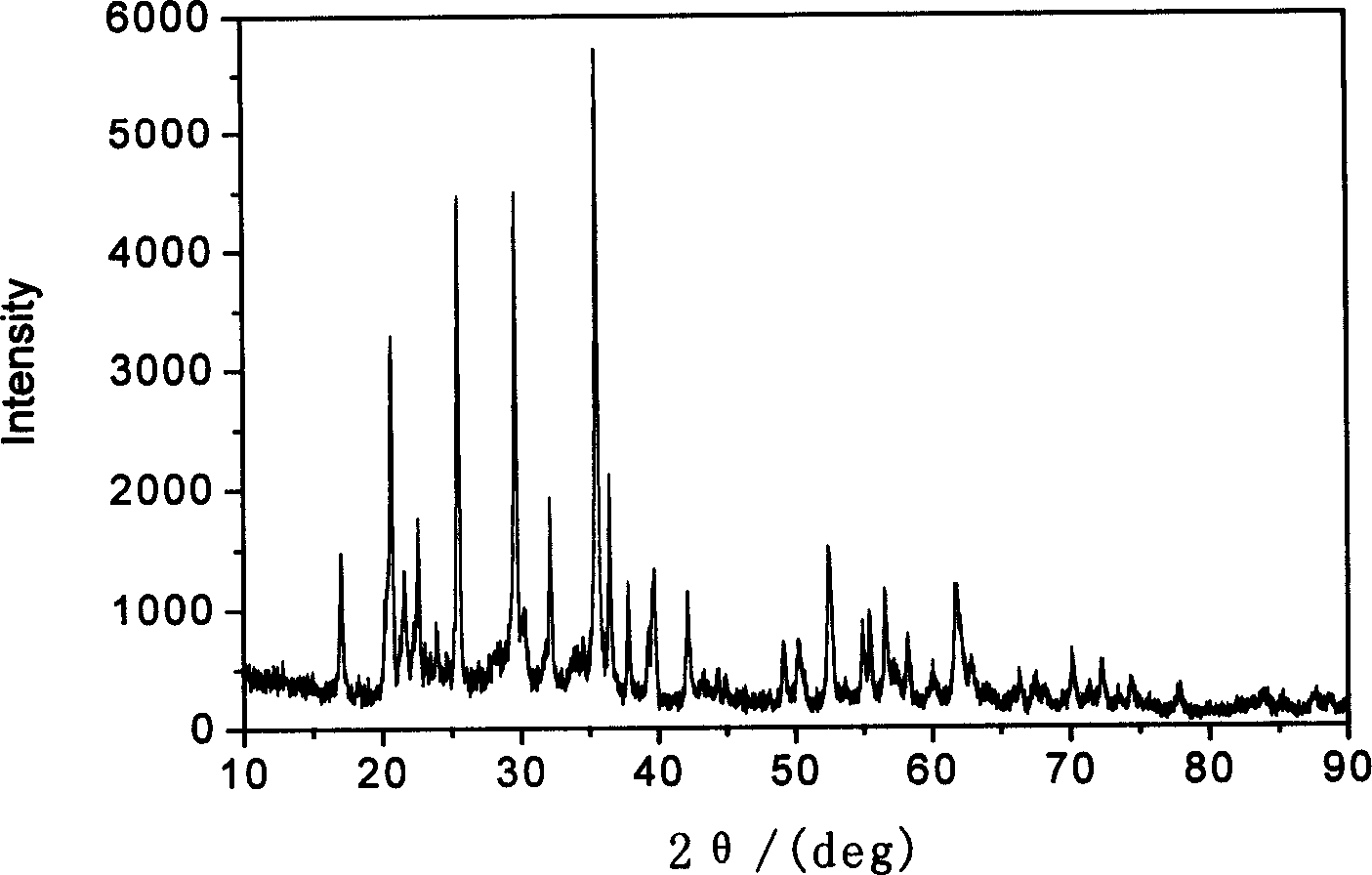

[0020] Press the dry material into tablets, put it into an alumina crucible equipped with activated carbon and heat-insulating materials, then place the crucible in a household microwave oven (frequency 2.45 GHz), adjust the power to the second gear of low heat, and microwave for 9 minutes. The phase analysis results of the obtained sample are shown in image 3 . It can be seen from the XRD pattern that the synthesized product is olivine-type LiFePO 4 , basically no impurity phase.

[0021] The synthetic material is added with a conductive agent and a binder (20% and 5% respectively) is bonded and pressed to form a film, and a test battery is formed with metal lithium, and a constant current charge and discharge experiment is carried out. The charge and discharge current is 10mA / g, and the charge and discharge voltage range Control between 2.5-4.2V. Figure 4 The 2-7 charge and discharge curves are given, and the specific capacity can reach more than 70mAh / g.

example 3

[0023] Press the dry material into tablets, put it into an alumina crucible equipped with activated carbon and insulation materials, then place the crucible in a household microwave oven (frequency 2.45 GHz), adjust the power to medium and low heat, and microwave for 3 minutes. The phase analysis results of the obtained sample are shown in Figure 5 . It can be seen from the XRD pattern that the synthesized product is olivine-type LiFePO 4 , no impurity phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com