Magnesium diaphragm, method for manufacturing the same, and speaker using the diaphragm

A manufacturing method and technology for loudspeakers, which are applied in manufacturing tools, diaphragm structures, metal material diaphragms, etc., can solve the problems of large internal loss, speaker performance deterioration, magnesium performance deterioration, etc., and achieve high internal loss, improved sensitivity, high The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

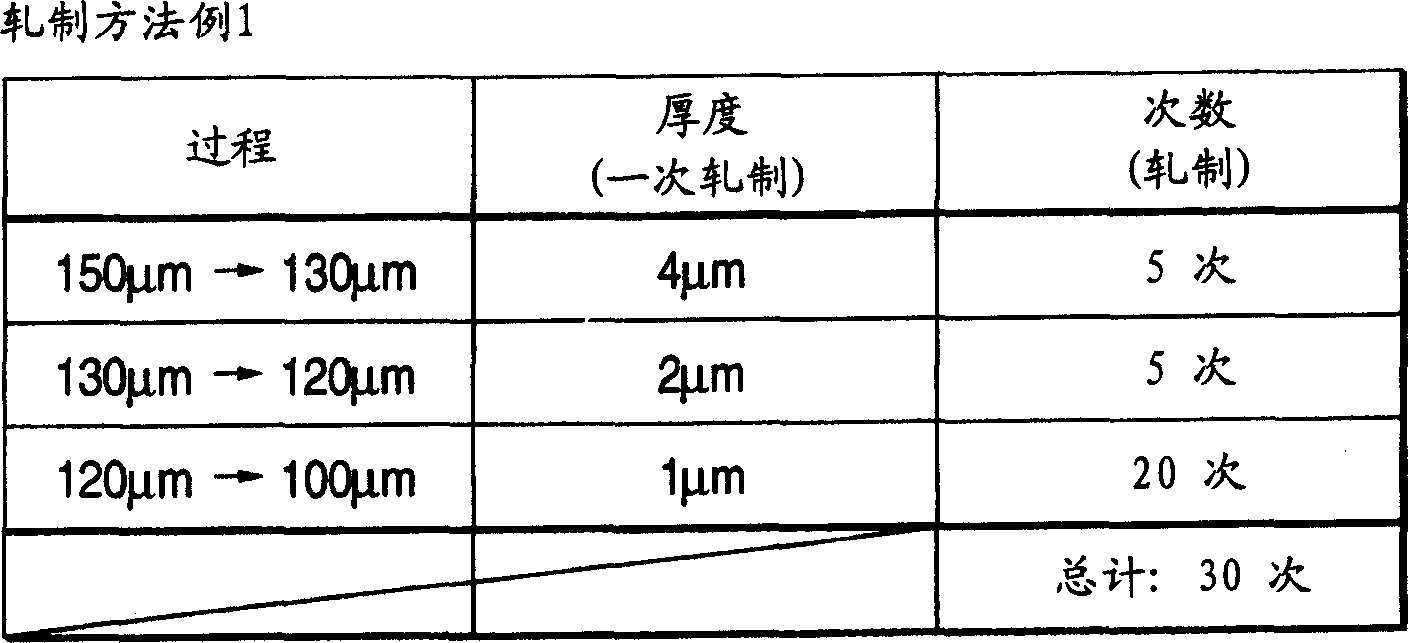

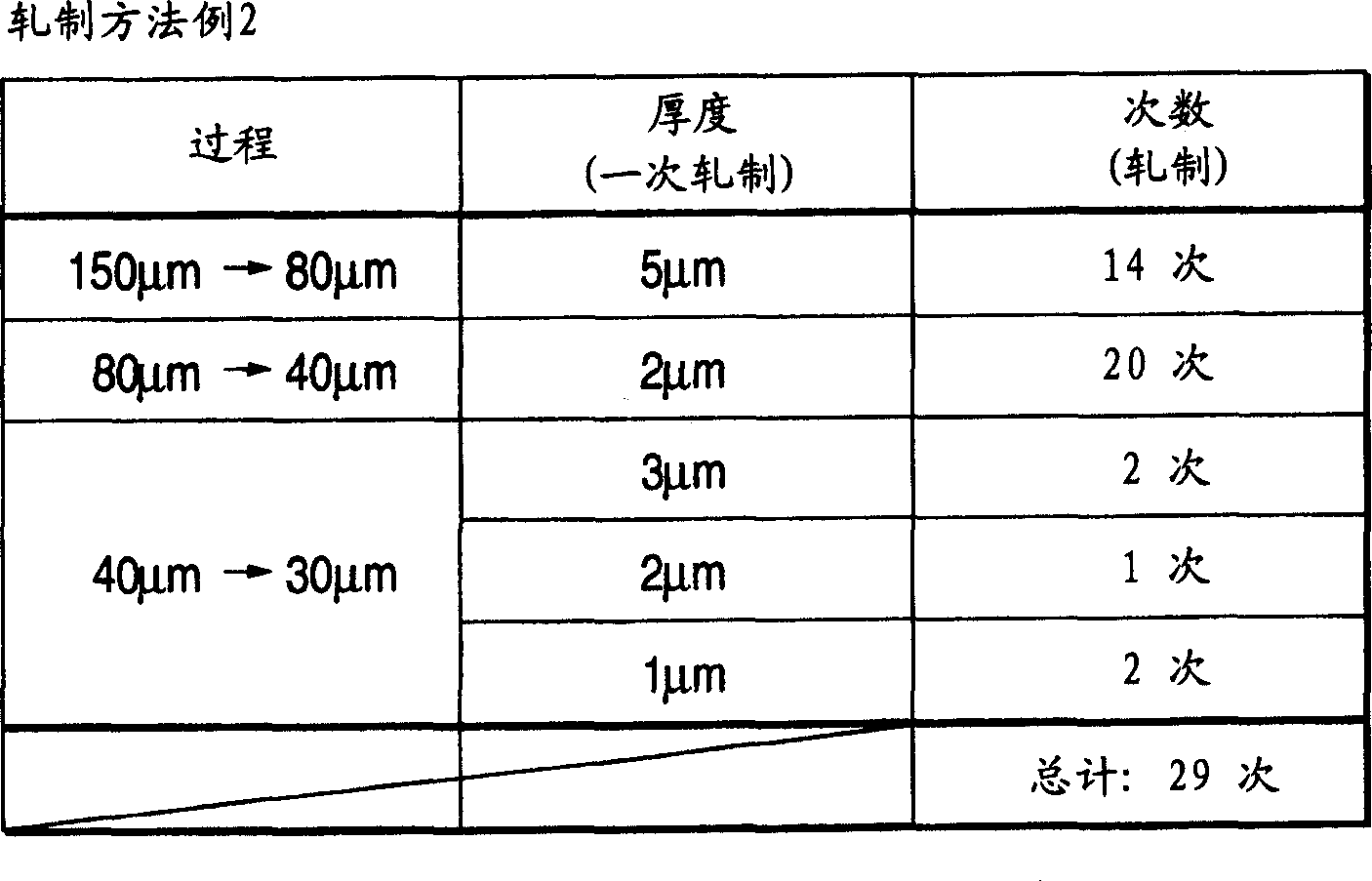

[0031] In the present invention, the tweeter uses a magnesium sheet rolled to a thickness of 30 μm to 100 μm as a diaphragm, and the speaker can obtain high internal loss, prevent sensitivity drop, and obtain low distortion without oxidation. A rolling method for rolling a magnesium diaphragm with a thickness of 30 μm to 100 μm; output sound pressure characteristics of the magnesium diaphragm in a high frequency range; and the magnesium diaphragm formed into Examples of various shapes and applications applied to tweeters.

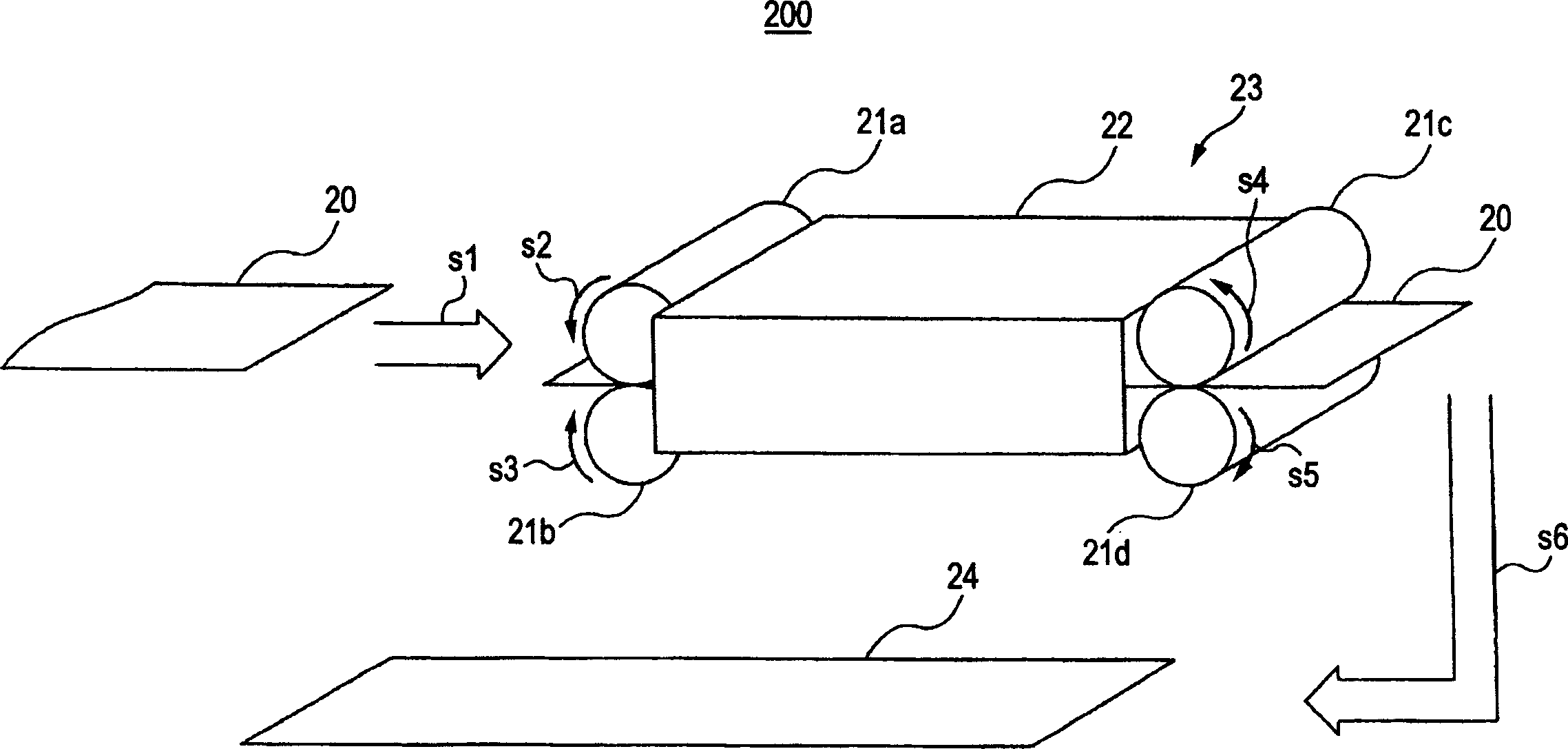

[0032] First, refer to figure 1 The method for rolling magnesium of the present invention will be described. figure 1 A rolling process 200 is shown for rolling a rolled magnesium substrate 20 into a magnesium sheet 24 having a thickness of 30 μm to 100 μm.

[0033] It is preferable to form the magnesium substrate 20 into a sheet h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com