Low-sulfur diesel oil multi-effect additive composition

A low-sulfur diesel oil and composition technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of diesel stabilizers without clean dispersion, oil solubility is not very good, diesel oxidation sediment inhibition ability is not strong, etc. Achieve anti-oxidation ability, clean dispersion performance, strong adsorption and capture ability, good anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

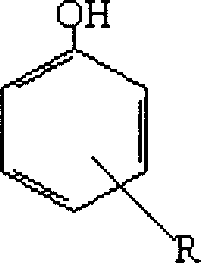

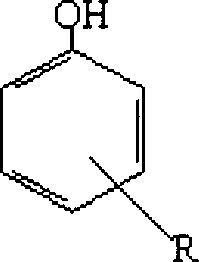

[0037] This example is the preparation of polyalkenylphenol:

[0038] In a 1000ml three-necked bottle, add 363.3 grams of polyisobutene (polyisobutene number-average molecular weight Mn=1100, the source is Jinzhou Petrochemical Company] and 62.1 grams of phenol, stir and heat to 50 ° C, and 14.1 grams of BF 3 - Diethyl ether solution was added dropwise to the reaction system three times in about two hours. The temperature was raised to 60°C, and the reaction was timed for 4.5 hours. Stop the reaction, wash with hot distilled water three times, and then distill under reduced pressure to remove unreacted phenol. The conversion rate is calculated by column chromatography analysis method, and the unreacted polyisobutene in the petroleum ether is 32%, so the conversion rate of the alkylation is 68%.

example 2

[0040] This example is the preparation of polyalkenylphenol:

[0041] In a 1000ml three-necked bottle, add 200 grams of polyisobutene (polyisobutene number-average molecular weight Mn=1000, the source is BASF, Germany) and 37.6 grams of phenol, stir and heat to 60 ° C, and 8.6 grams of BF 3 - Diethyl ether solution was added dropwise to the reaction system three times in about two hours. The temperature was raised to 70°C, and the reaction was timed for 4 hours. Stop the reaction, wash with hot distilled water three times, and then distill under reduced pressure to remove unreacted phenol. The conversion rate is calculated by column chromatography analysis method, and the unreacted polyisobutene in the petroleum ether is 30%, so the conversion rate of the alkylation is 70%.

example 3

[0043] This example is the synthesis of Mannich base:

[0044] In the three-necked flask, add 100 grams of polyalkenyl phenol prepared by Example 1, 9.4 grams of triethylenetetramine and 120 grams of toluene, heat and stir to 70 ° C, and drop 13.4 grams of 36% formaldehyde solution within 2 hours into the reaction system (the molar ratio of polyalkenylphenol, formaldehyde and triethylenetetramine is 1:3:1.2). After dropping, the temperature was raised to 100°C, and the reaction was timed at 100°C for 2 hours. Then remove toluene solvent and water with vacuum distillation, add 50 grams of aromatics diluent oil again, be made into about 50% dilution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com