High precision combined optical grating device for optical 3D measurement

A three-dimensional measurement, high-precision technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of inability to effectively ensure accurate grating alignment, small grating size, low maximum light intensity, etc., and achieve important engineering practical value, guarantee Accuracy and stability, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

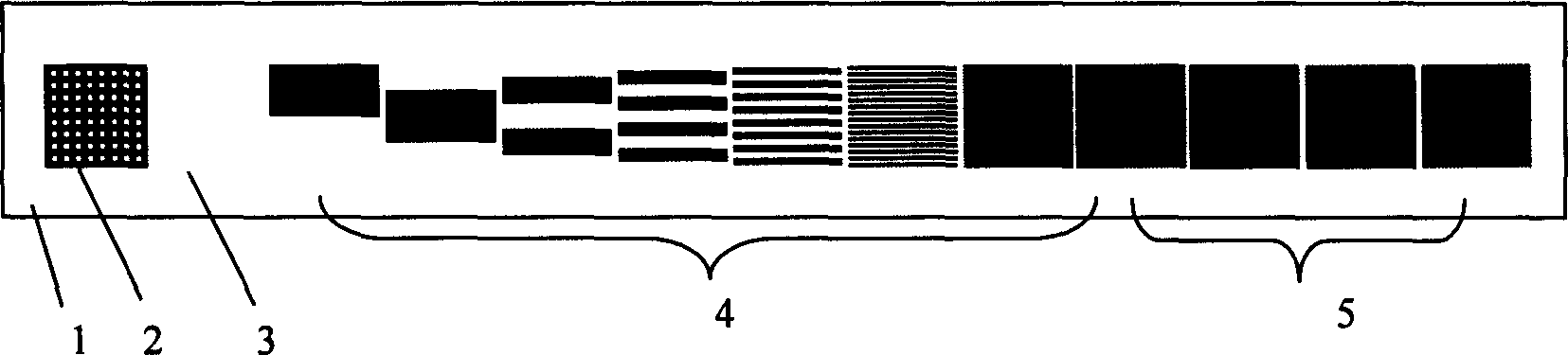

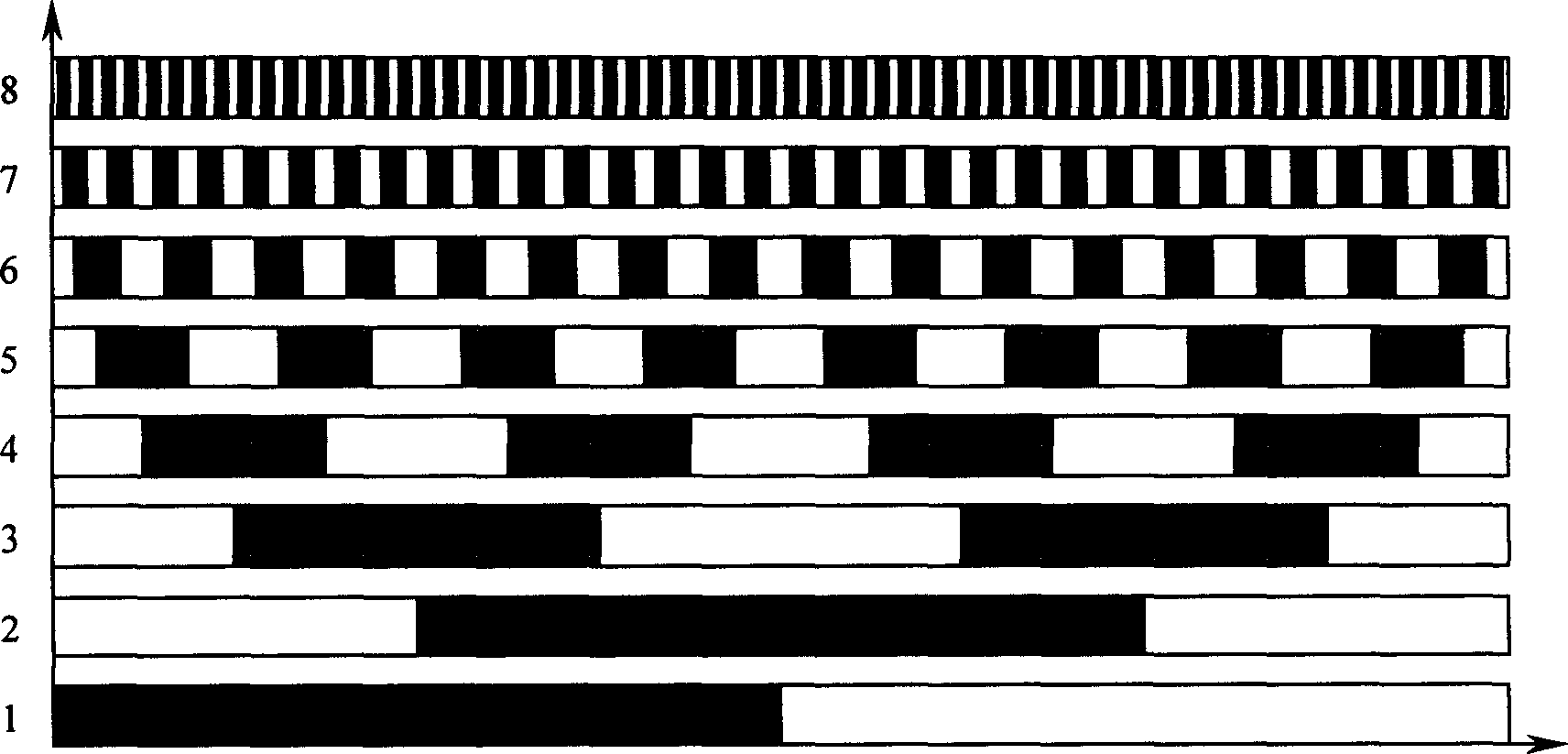

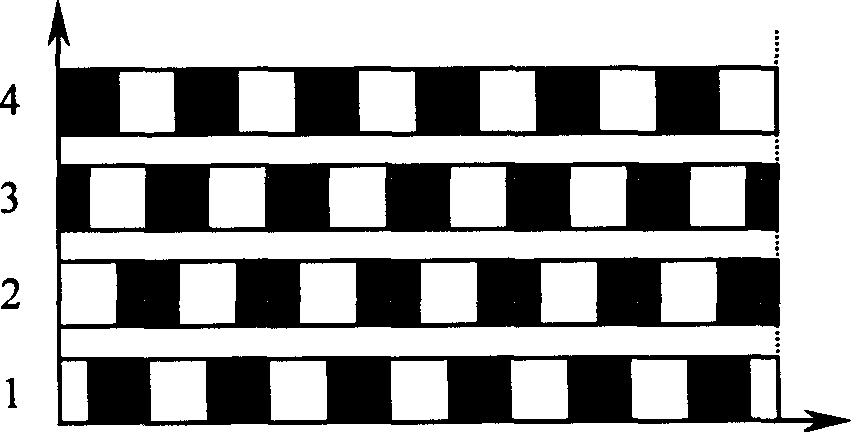

[0015] like figure 1 As shown, the combined grating device of the present invention mainly adopts the method of electron beam scanning lithography to sequentially engrave 13 grating diagrams on the quartz glass sheet 1 for lithography with a very small expansion rate. The first frame is the projector calibration grating 2, the second frame is the all-white grating 3, the third to the tenth frame is the Gray code grating 4, and the 10th to the 13th frame is the phase shift grating 5. like figure 2 As shown, the black and white stripes in the Gray code grating 4 represent logical values 0 and 1 respectively, then the eight gratings form an 8-bit Gray code, and the width of each grating edge stripe is half the width of the middle stripe. The grating starts, and the width of the subsequent fringes is successively reduced by half compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com