Oxygen enrichment combustion-supporting method for float glass melter

An oxygen-enriched combustion-supporting, float glass technology, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve problems such as too large fluctuations in nitrogen supply pressure, restrictions on the exploration and experimentation of oxygen-enriched combustion-supporting technology, and affect continuous implementation. Achieve the effect of avoiding cooling effect, reasonable distribution and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

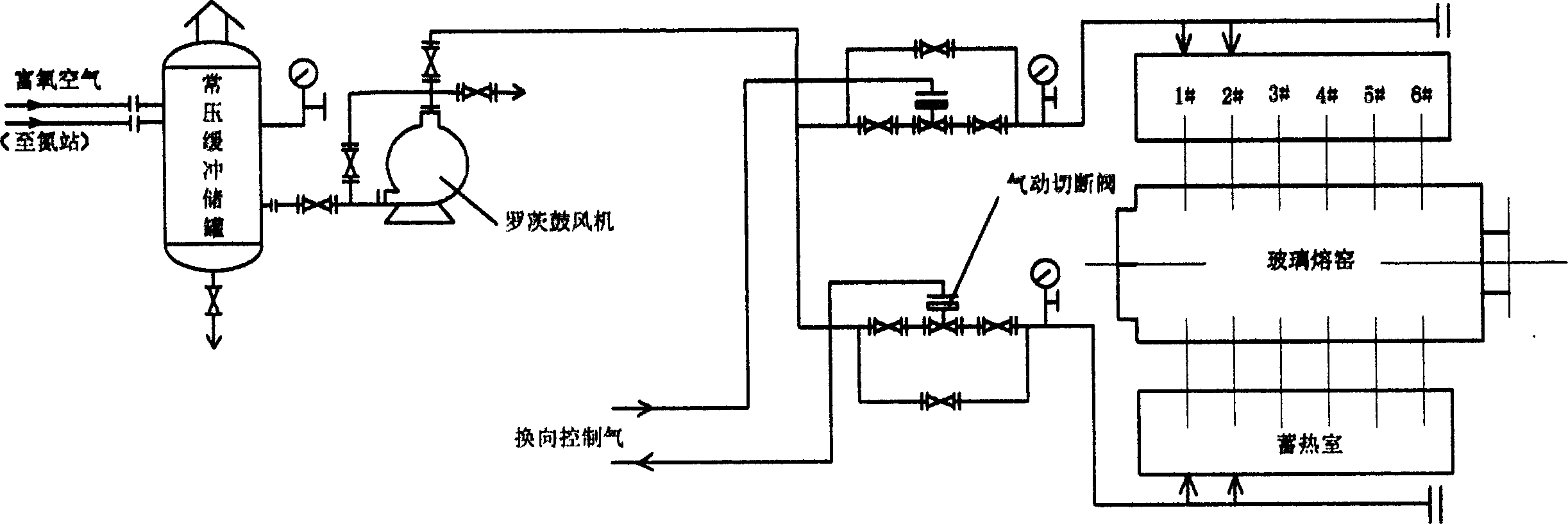

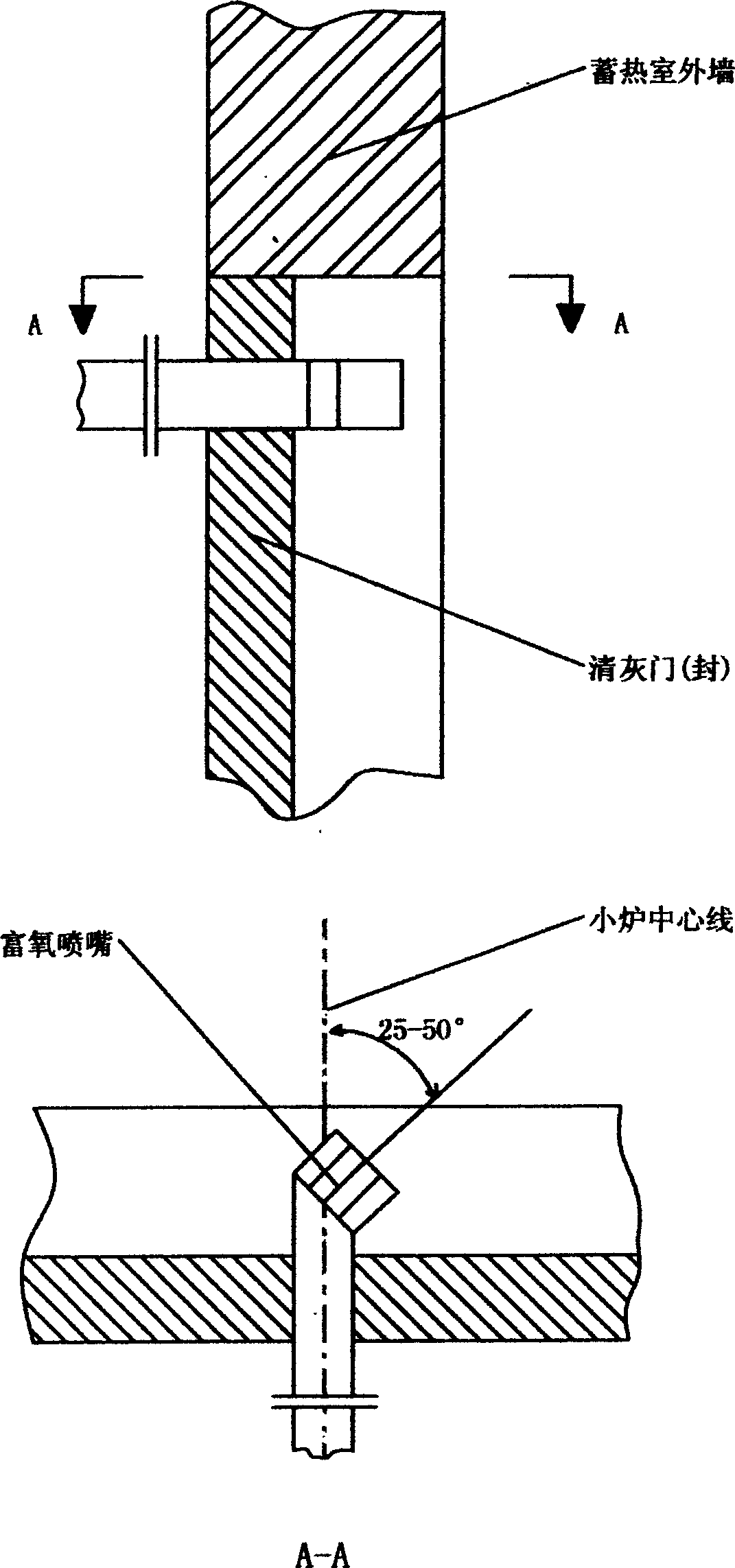

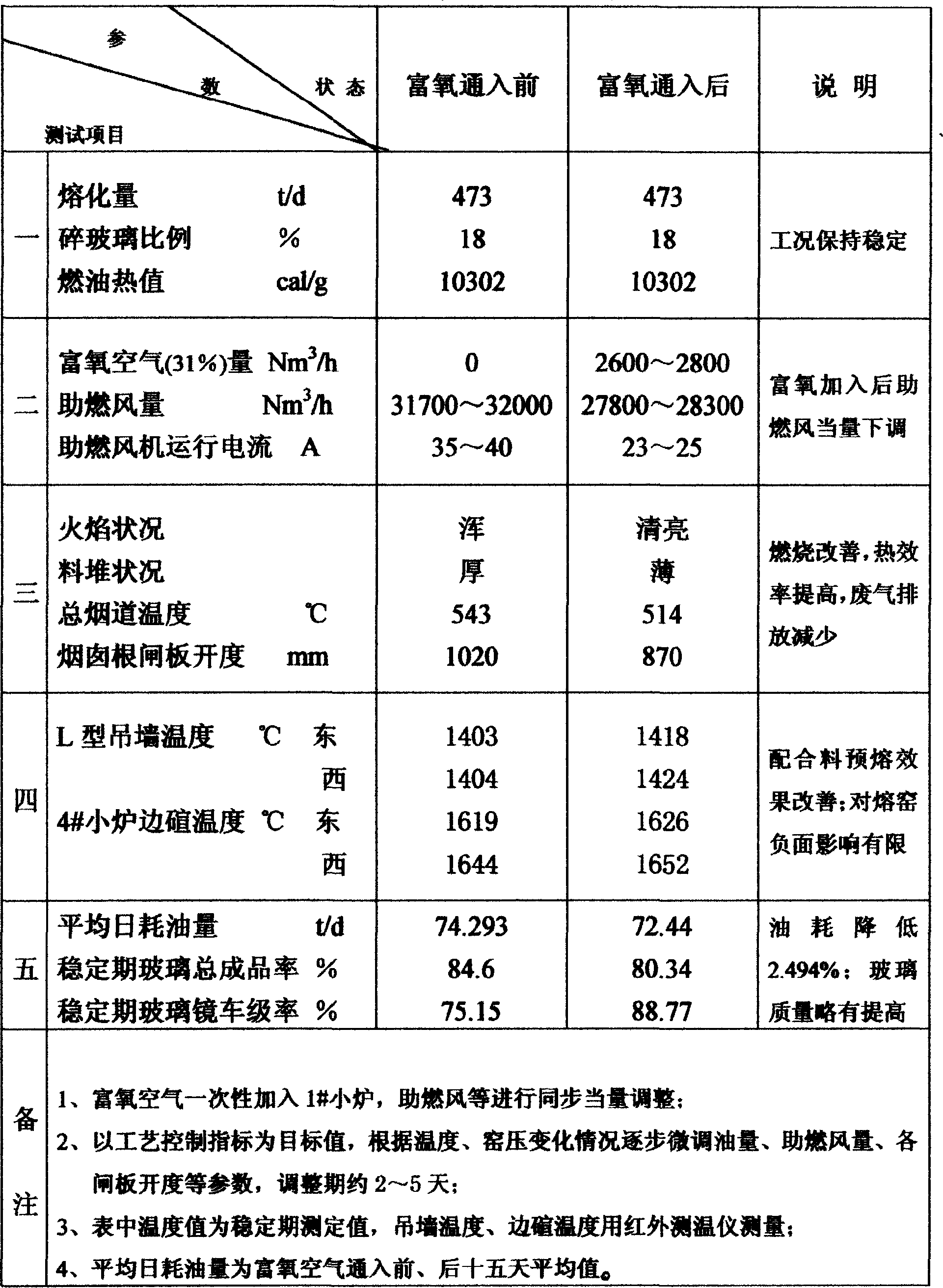

[0010] A method for oxygen-enriched combustion in a float glass melting furnace according to the present invention, such as figure 1 , figure 2 As shown, the purifier of the air separation nitrogen unit and the oxygen-enriched air from the fractionation tower are respectively connected to the buffer storage tank at normal pressure. Float joint workshop, after entering the workshop, the oxygen-enriched air main pipe is divided into two routes, respectively controlled by a pneumatic cut-off valve (synchronized with the combustion air), and led to both sides of the regenerator of the glass melting furnace, and then along 1 # ,2 # The center line of the small furnace leads to a branch pipe, and a control valve is set on the branch pipe, and then the oxygen-enriched nozzle is introduced into the soot cleaning door of the regenerator.

[0011] In order to keep the nitrogen production system unaffected and maintain a stable nitrogen supply, an atmospheric pressure buffer storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com