Preparation process of diglyceride

A technology of diglyceride and glycerol, which is applied in the field of preparation of diglyceride, can solve the problems of reduced enzyme catalysis efficiency, reduced encapsulation, poor compatibility, etc., and achieves the effect of improving catalytic effect and solving encapsulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

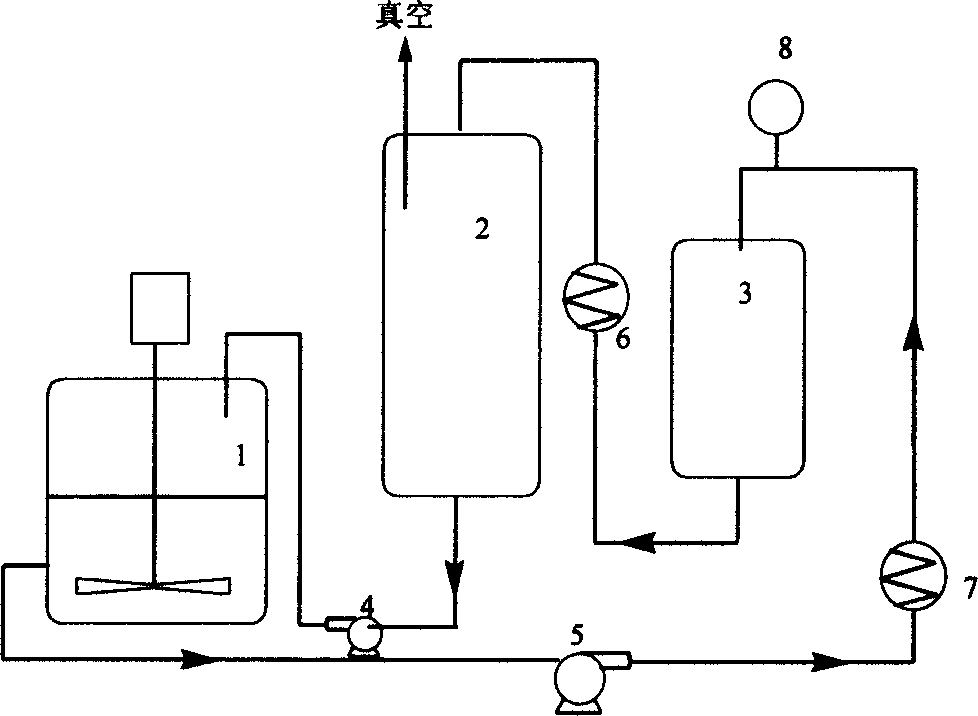

[0037] as attached figure 1 As shown, add 450g of oleic acid, 30g of glycerin and 60g of 100-mesh coarse-pore silica gel to the raw material tank 1, and the remaining 70g of glycerin is fed in during the reaction process, and the speed of feeding is controlled to prevent obvious agglomeration of the silica gel. Load immobilized lipase Lipozyme RM IM 30g into the enzyme reactor 3 to form a packed bed reactor, and the volume of the enzyme reactor is 100ml. Lipozyme RM IM (product of Novozymes) is a commercially available immobilized 1,3-position-specific lipase, which is immobilized with a macroporous anion resin. The bulk density of this product is about 0.4kg / L. According to the Novozymes product specification, it is expressed by acid hydrolysis reaction, the lipase activity is 5-6 BAUN / g, and BAUN is the abbreviation of Batch Acidolysis Unit Novo (Novozymes batch acid hydrolysis unit). The reactant in the tank 1 is continuously transported through the enzyme reactor 3 throug...

Embodiment 2

[0039] All 48g of glycerol was added by feeding method, the amount of immobilized lipase Lipozyme RM IM was 2.5g, the volume of the enzyme reactor was 100ml, the enzyme reactor was stirred by a magnetic stirrer, the amount of silica gel was 4.8g, and the reaction time was 24 hours. Operating condition is the same as embodiment 1. The results are shown in Table 1 and Table 2.

Embodiment 3

[0041]The amount of silica gel added was 118g, and 147g of glycerin was added in two averages, respectively at the beginning and after 2 hours of reaction, and the rest of the operating conditions were the same as in Example 1. The results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com