Method for producing products of tubular meta casing body

A production method and metal shell technology, applied in the field of mechanical processing, can solve the problems of large consumption of materials, low production efficiency, large wall thickness tolerance, etc., and achieve the effects of improving process conditions, high processing accuracy and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] A processing and production method for tubular metal shell parts, which takes a φ107mm×2.5mm×177.8mm compressor cylinder as an example, and its production steps are:

[0037] 1. Preparatory steps before machining:

[0038] 1. Pipe input. Raw material tube φ120×3.0mm; material: Baosteel SPHC.

[0039] 2. Cut the pipe. Cut to length according to specifications φ120×3.0×150mm.

[0040] 3. Phosphorus and saponification treatment. Carry out according to chart 4.

[0041] 2. Mechanical processing steps:

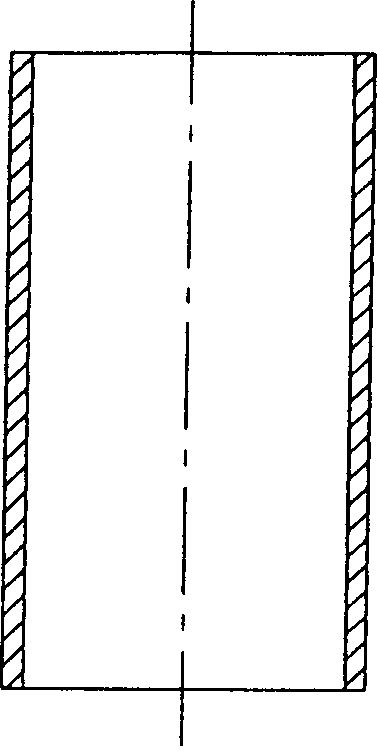

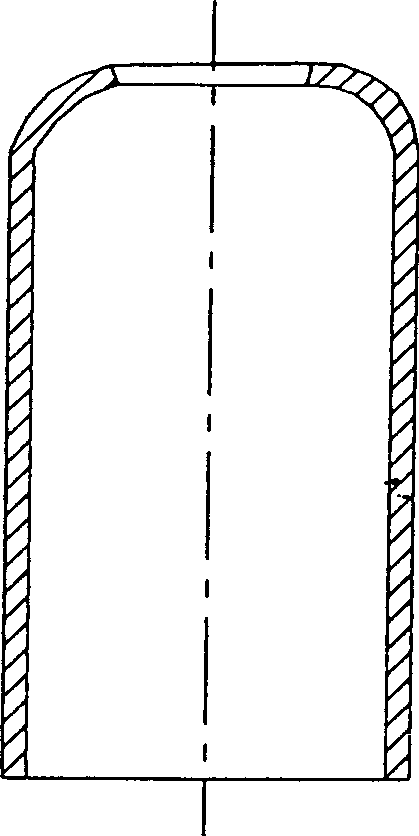

[0042] 4. Pier head. The diameter of the shrinkage is about φ105±1.0mm (see attached figure 2 ).

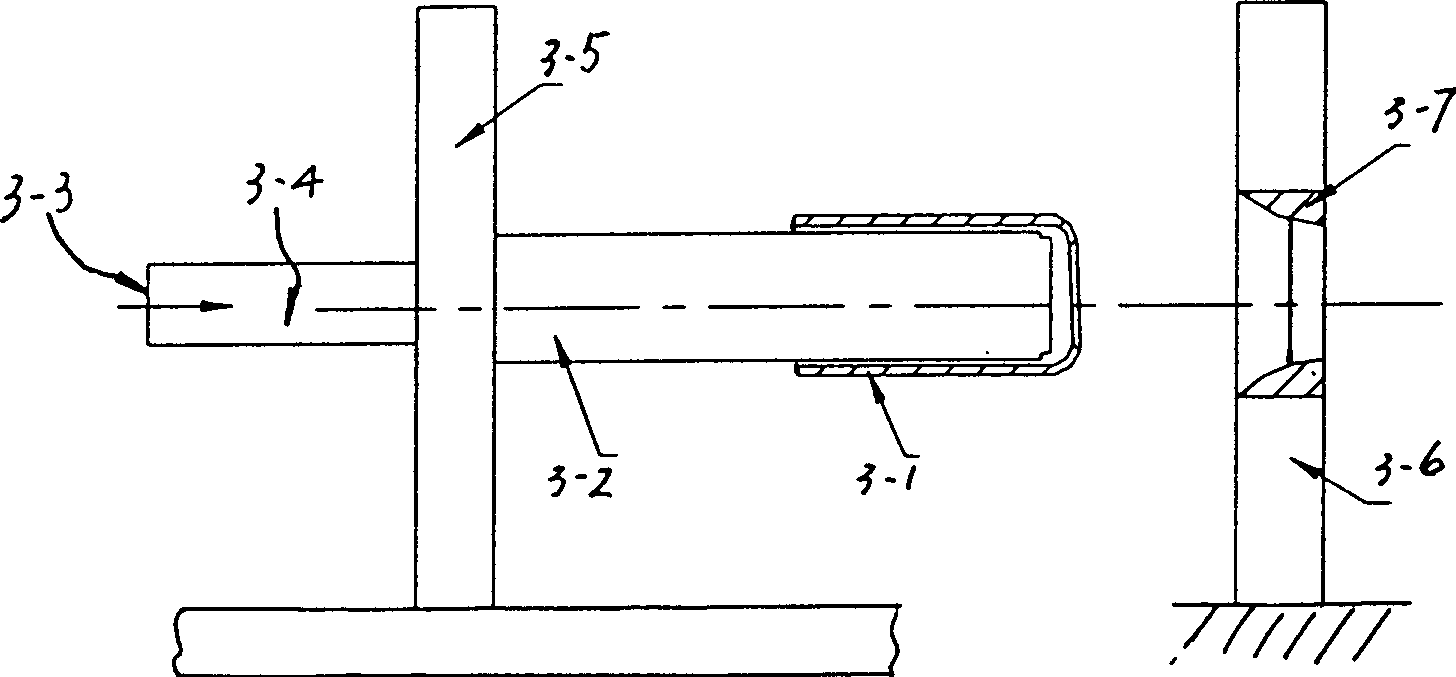

[0043] 5. Cold extrusion. Outer mold: φ107±0.015mm; mandrel: 102±0.015mm; workpiece moving speed is 6 m / s (see attached image 3 ).

[0044] 6. Cut off. Length 180±0.5mm.

[0045] 7. The two ends of the workpiece are processed by turning. Keep the total length 177.8±0.05mm.

[0046] 3. Processing steps after machining:

[0047] 8. Remove the saponified film on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com