Thermal-insulation anti-cracking composite coating

A composite coating and anti-cracking technology, which is applied in the direction of filling slurry, etc., can solve the problems that cracks are difficult to eliminate, and cannot have high strength and high thermal insulation performance, so as to avoid cracks that are difficult to eliminate, save indoor space and cost, effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

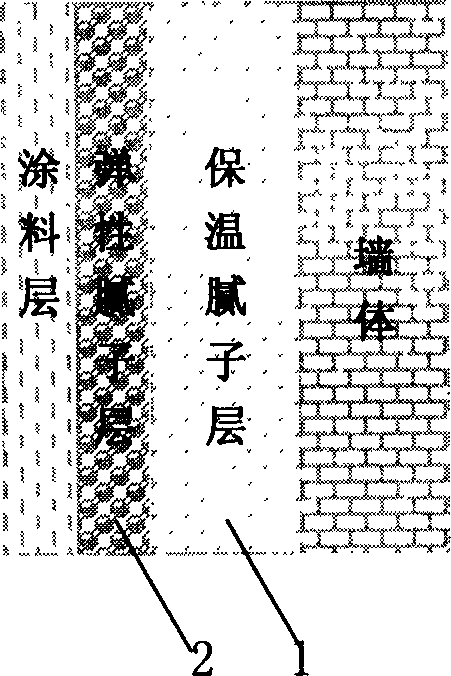

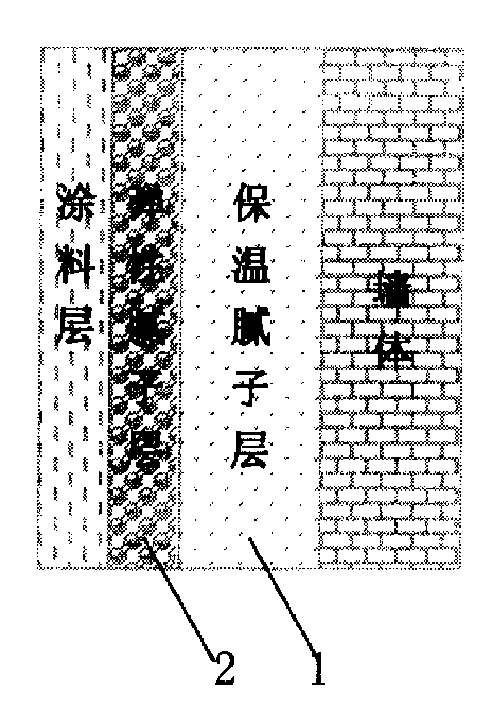

[0015] 1. The production method of inner wall thermal insulation putty (1)

[0016] Put 300kg of expanded perlite, 600kg of acrylic emulsion, 100kg of methyl cellulose colloid, 10kg of sodium methyl siliconate, and 1kg of sodium benzoate into a mixer according to a conventional method and stir evenly. According to the above production method, the main performance indicators of the interior wall thermal insulation putty are: compressive strength ≥ 0.5Mpa; shear strength ≥ 0.25Mpa; thermal conductivity ≤ 0.08w / m.k.

[0017] 2. How to make elastic putty (2)

[0018] Pour 400kg of light calcium carbonate, 200kg of acrylic elastic emulsion, 100kg of methyl cellulose colloid, 1kg of sodium benzoate, and 200g of defoamer into the mixer, and stir evenly according to the conventional method. According to the above production method, the main performance indicators of the elastic putty are: drying time (surface dry) 0.25Mpa; dynamic crack resistance ≥0.5mm.

[0019] 3. The effect of t...

Embodiment 2

[0033] Put 308kg of expanded perlite, 660kg of acrylic emulsion, 121kg of methyl cellulose colloid, 10.1kg of sodium methyl siliconate, and 0.88kg of sodium benzoate into a mixer according to a conventional method and stir evenly to make an inner wall thermal insulation putty. Pour 342kg of light calcium carbonate, 174kg of acrylic elastic emulsion, 82.8kg of methyl cellulose colloid, 0.72kg of sodium benzoate, and 150g of defoamer into the mixer, and stir evenly according to the conventional method to make elastic putty. Other implementation conditions are as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com