High fluidity nano talcum powder modified polypropylene composite material and its preparation method

A nano-talc, high-fluidity technology, applied in the field of nano-composite materials and their preparation, can solve the problems of decreased impact strength and elongation at break, and achieve improved fluidity and toughness, impact strength and elongation at break. The effect of improving the tensile strength, impact strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

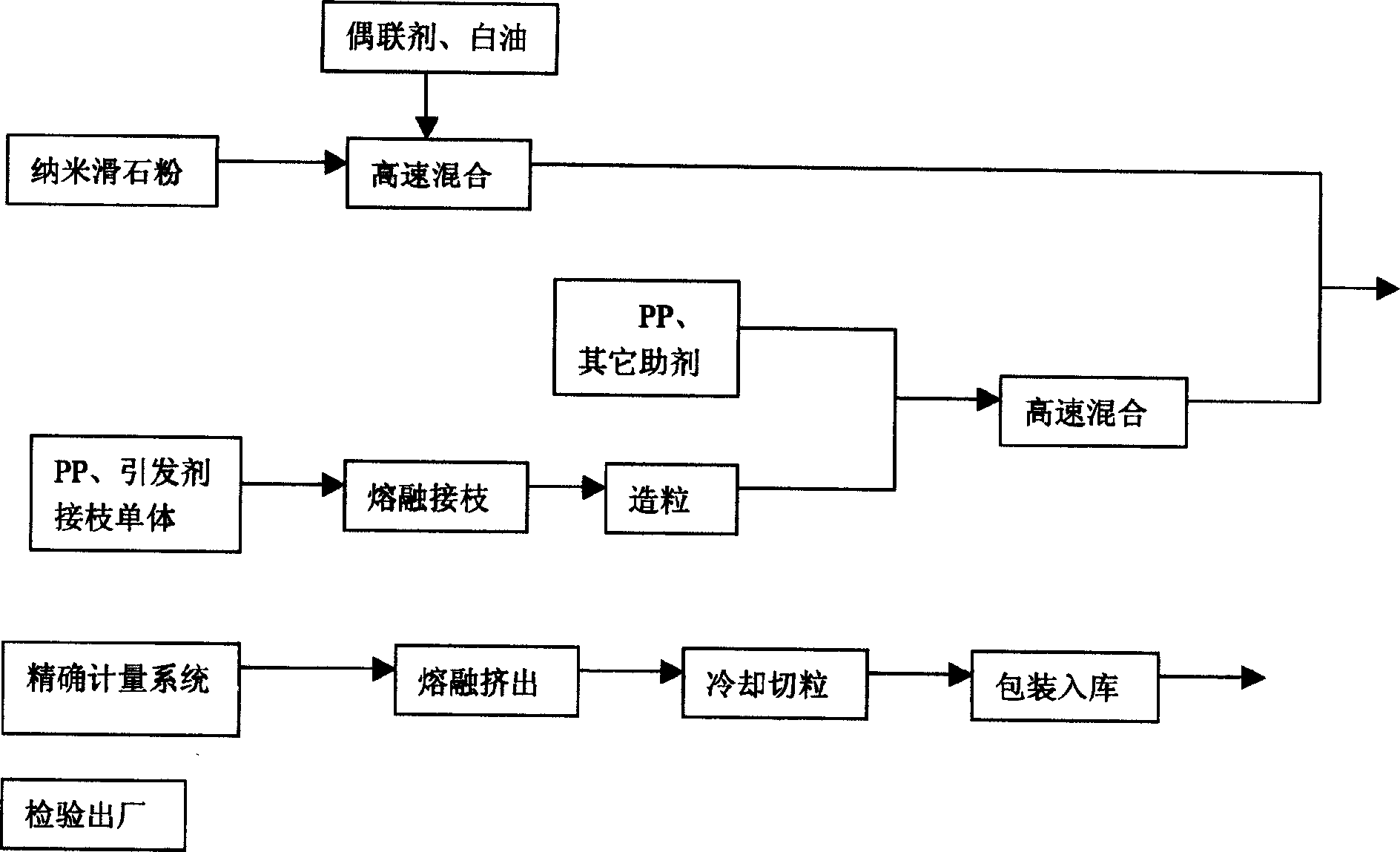

Image

Examples

Embodiment 1

[0037]Embodiment 1: 30 kilograms of nano talc powders with an average size of 30-120 nm are first put into a high mixer (set heating temperature is 110° C.). Start the high-mixer at a low speed, and then add 0.8 kg of γ-aminopropyltriethoxysilane (KH-550) diluted with white oil (0.4 kg of white oil, 0.4 kg of KH- 550), high-speed stirring treatment after 30 minutes, discharging to obtain mixture A2; simultaneously the weight ratio is: polypropylene is 100 parts, methyl methacrylate grafted polypropylene is 15 parts, and polyolefin elastomer (POE) is 20 parts , 2 parts of γ-aminopropyltriethoxysilane (KH-550), and 4 parts of microcrystalline paraffin. The above-mentioned substances are mixed by a high-speed mixer to obtain a mixture A1; then the mixtures A1 and A2 are fed into the Twin-screw or reciprocating single-screw extrusion equipment. The feeding ratio of A1 and A2 is set to be 141:50 through feeding control. The material is fully plasticized, melted and compounded und...

Embodiment 2

[0038] Embodiment 2: First put 30 kilograms of nano talcum powder with an average size of 30-120 nm into a high mixer (set heating temperature to be 110° C.). Start the high-mixer at a low speed, and then add 0.8 kg of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane (KH-792) diluted with white oil after the temperature of the material rises to 80°C (including 0.4 kilograms of white oil, 0.4 kilograms of KH-792), high-speed stirring treatment 30 minutes after discharge to obtain mixture A2; simultaneously the weight ratio is: polypropylene is 100 parts, butyl acrylate grafted polypropylene is 8 parts, N-β -(Aminoethyl)-γ-aminopropyltrimethoxysilane (KH-792) is 4 parts, ethylene-propylene rubber (EPR) is 24 parts, polyethylene wax is 1.3 parts, and the above-mentioned materials are mixed by a high-speed mixer The mixture A1 is obtained; then the mixtures A1 and A2 are sent into twin-screw or reciprocating single-screw extrusion equipment by a precision metering device. The feedi...

Embodiment 3

[0039] Embodiment 3: first put 30 kilograms of nano talc powder with an average size of 30-120nm into a high mixer (set heating temperature to be 110° C.). Start the high-mixer at a low speed, and then add 0.6 kg of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) diluted with white oil after the temperature of the material rises to 80°C (of which 0.3 kg of white oil, 0.3 kg KH-560), high-speed stirring treatment after 30 minutes discharging to obtain mixture A2; simultaneously the weight ratio is: polypropylene is 100 parts, pentaerythritol triacrylate grafted polypropylene is 5 parts, polyolefin elastomer (POE) is 8 2.5 parts of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560), 0.8 parts of EBO (N, N`-ethylene bisoleamide), and the above-mentioned materials are mixed by a high-speed mixer to obtain a mixture A1; then the mixtures A1 and A2 are sent into twin-screw or reciprocating single-screw extrusion equipment by a precision metering device. The feeding ratio of A1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com