Method for fabricating a nanoarray using the self-assembly of supramolecules and staining of metals

A supramolecular, self-assembly technology, applied in chemical instruments and methods, biochemical equipment and methods, nanotechnology, etc., can solve the problems of complex thin film structure, failure to develop diagnostic protein nanochips, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of the DNA chip in the biological chip of the present invention includes the step of connecting the pre-prepared probes to the surface of the solid substrate by means of a spotting method. In this case, the amine-bound probe is dissolved in 1X to 7X, preferably 2X to 5X, more preferably 3X SSC buffer solution (0.45M NaCl, 15mM C 6 h 5 Na 3 o 7 , pH 7.0), and then use a microarray spotter to spot it onto the substrate with aldehyde groups attached. Then, the probes are immobilized on the substrate by utilizing the interaction between aldehyde groups and amine groups. The concentration of probe used is greater than 10 pmol / μl, preferably greater than 50 pmol / μl, more preferably greater than 100 pmol / μl. The amine group combined with the probe and the aldehyde group combined with the substrate react with each other for 4-8 hours, preferably 5-7 hours, most preferably about 6 hours under the condition of 70-90%, preferably 80%, in humidity, so tha...

Embodiment 1

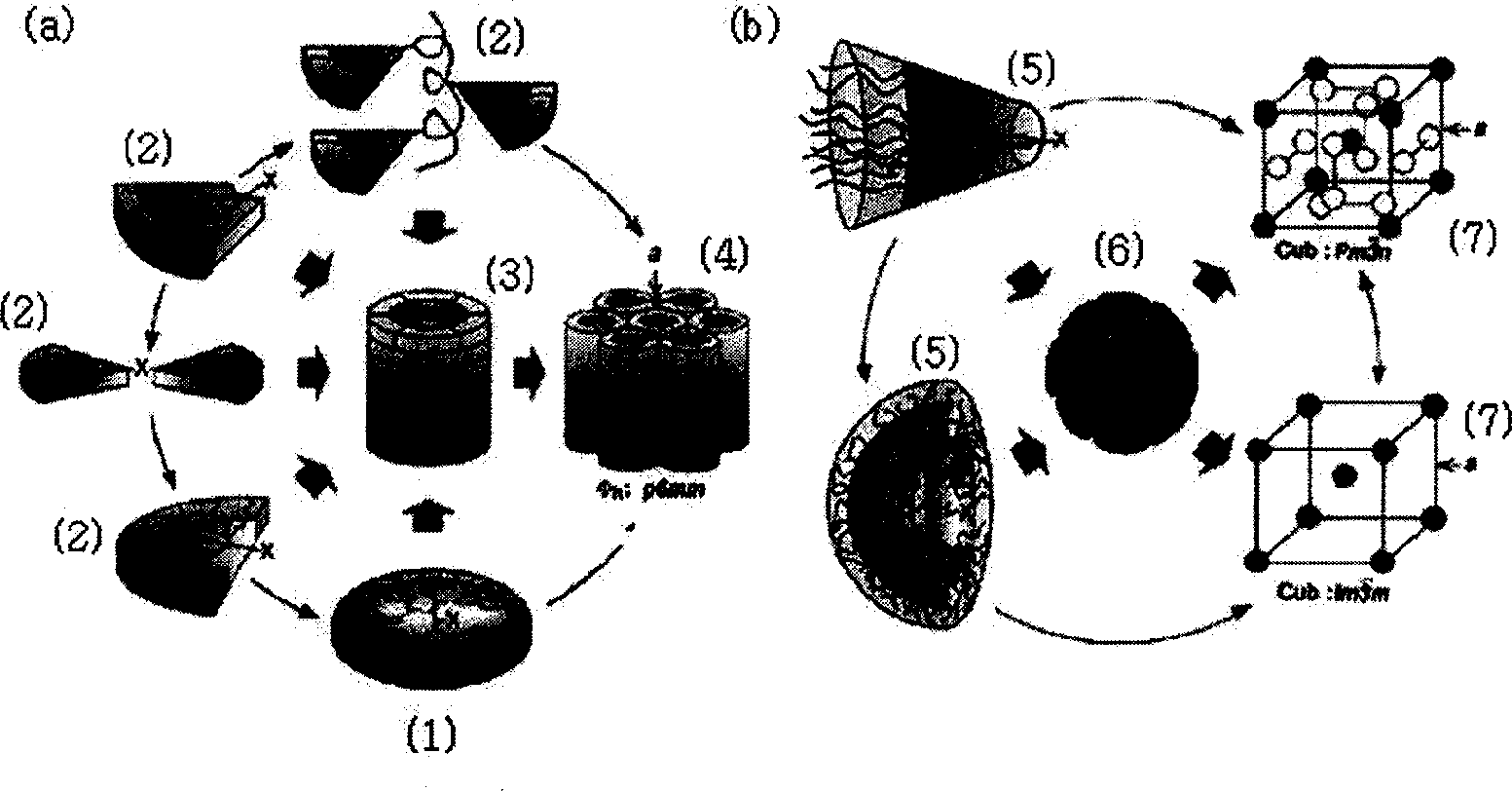

[0067] Embodiment 1: the synthesis of supramolecular

[0068] The supramolecule of formula (1) used in the present invention is synthesized through the steps of the following reaction scheme (1). The scanning electron microscope analysis of the supramolecule confirmed that the supramolecule is a regular cylindrical structure of nanoscale or smaller scale.

[0069] (Reaction Diagram 1)

[0070]

Embodiment 2

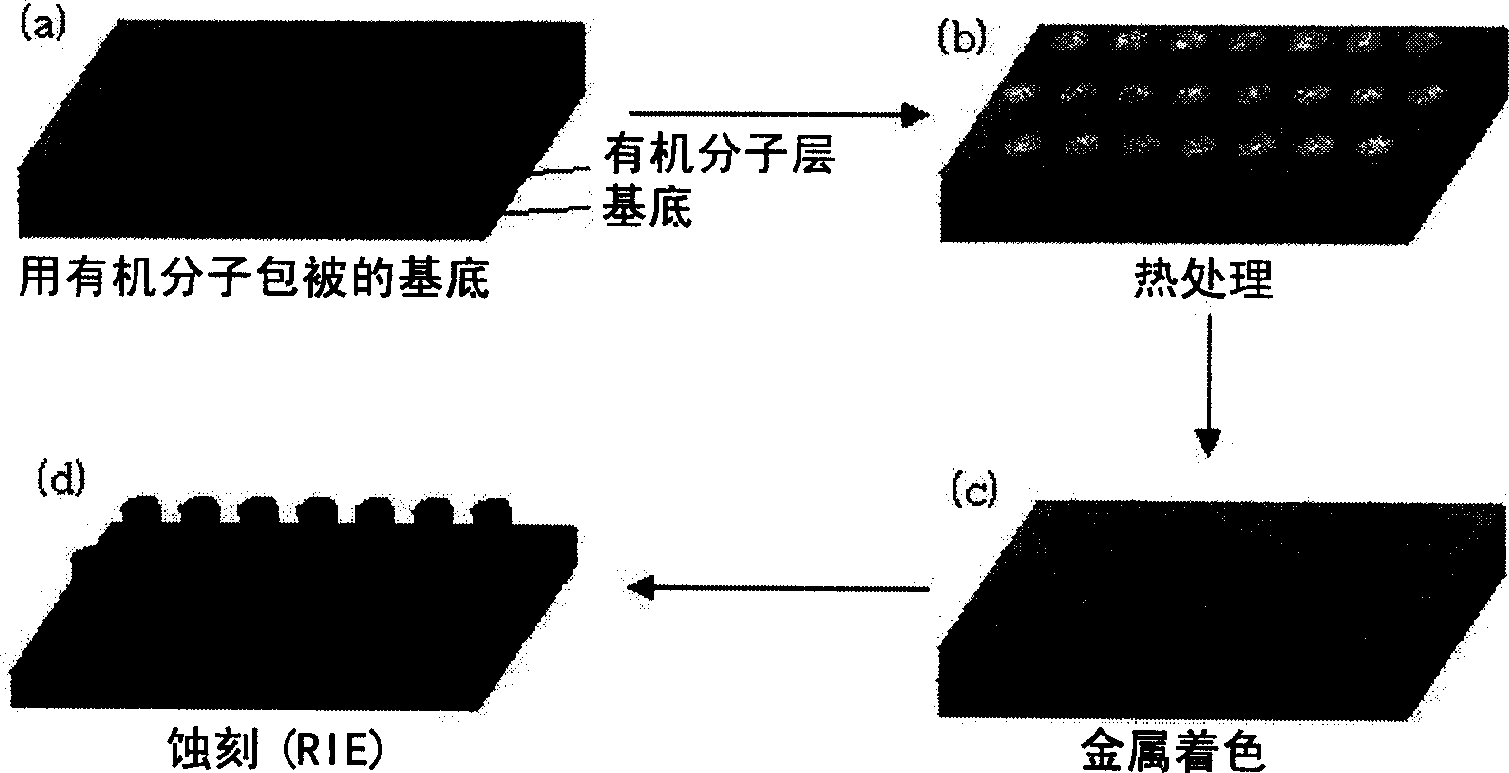

[0071] Embodiment 2: substrate surface modification

[0072] In the present invention, a silicon wafer is used as a substrate. Metallic, non-metallic, or other thin films may be formed on the surface of the substrate, if desired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com