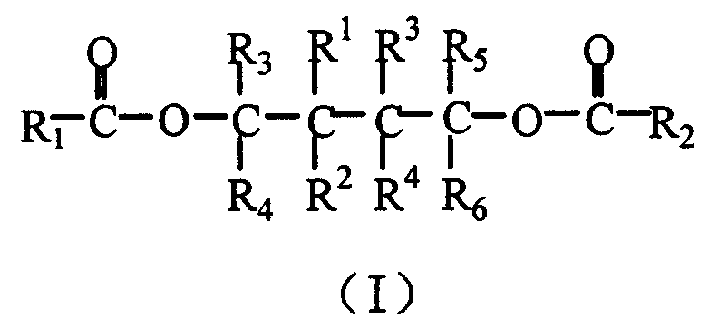

Glycol ester compound for preparing catalyst for olefinic polymerization

A compound and glycol ester technology, which is applied in the field of preparation of olefin polymerization catalysts, can solve the problems of low isotacticity of polymers, low catalytic activity of catalysts, and narrow molecular weight distribution of polymers, and achieves high stereospecificity and comprehensive performance. Excellent, wide molecular weight distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Synthesis of 2,3-diisopropyl-1,4-butanediol dibenzoate

[0034] (1) Synthesis of 2,3-diisopropyl-1,4-butanediol

[0035] The mixture of 5.1 g of lithium aluminum hydride and 120 ml of diethyl ether was cooled to 0°C, and at this temperature, a mixture of 11 g of diethyl 2,3-diisopropyl-1,4-succinate and 60 ml of diethyl ether was slowly added dropwise. After the addition, the temperature was raised to reflux and maintained at reflux for 1 hour. Then, it was lowered to 0°C, and 5ml of 15% sodium hydroxide solution and 20ml of water were added dropwise. After rising to room temperature, react for half an hour. After filtering, washing, drying and concentrating the organic phase, 8.4 g of product (76%) was obtained by distillation under reduced pressure. bp118°C / 0.1mmHg.

[0036] 1 H NMR (TMS, CDCl 3 , ppm): δ0.9 (14H), δ1.4 (2H), δ1.9 (4H), δ3.7 (2H).

[0037] (2) Synthesis of 2,3-diisopropyl-1,4-butanediol dibenzoate

[0038] 7.7 g of 2,3-diisopropyl-1,4-butanedi...

Embodiment 2

[0041] 2,3-Dimethyl-1,4-butanediol dibenzoate

[0042] With the preparation method of Example 1, the raw material 2,3-diisopropyl-1,4-diethyl succinate is changed to 2,3-dimethyl-1,4-diethyl succinate:

[0043] (1) 2,3-Dimethyl-1,4-butanediol

[0044] bp95℃ / 0.1mmHg; 1 H NMR (TMS, CDCl 3 , ppm): δ0.7~1.8 (8H), δ3.2~3.8 (4H), δ4.8 (2H).

[0045] (2) 2,3-Dimethyl-1,4-butanediol dibenzoate

[0046] 1 H NMR (TMS, CDCl 3 , ppm): 1.1-1.6 (8H), 5.0-5.5 (4H), 7.3-8.2 (10H).

Embodiment 3

[0048] 2,3-Diethyl-1,4-butanediol dibenzoate

[0049] With the preparation method of Example 1, the raw material 2,3-diisopropyl-1,4-diethyl succinate is changed to 2,3-diethyl-1,4-diethyl succinate:

[0050] (1) 2,3-diethyl-1,4-butanediol

[0051] bp110℃ / 0.1mmHg; 1 H NMR (TMS, CDCl 3 , ppm): 0.7-1.9 (12H), 3.3-3.9 (4H), 4.8 (2H).

[0052] (2) 2,3-Diethyl-1,4-butanediol dibenzoate

[0053] 1 H NMR (TMS, CDCl 3, ppm): 1.0-1.5 (10H), 2.1-2.3 (2H), 4.3-4.5 (4H), 7.3-8.1 (10H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com