Quenched skeleton cobalt base catalyst for cinnamyl aldehyde hydrogenation to prepare cinnamyl alcohol and its preparing method

A cobalt-based catalyst and catalyst technology, applied in the chemical industry, can solve the problems of high price, unsuitable cinnamyl alcohol, and the highest yield of less than 50%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Preparation of quenched Co-Al alloy

[0020] Metals Co and Al with a weight ratio of 40 / 60 were added to the quartz tube, and the sample was heated to 1573K in a high-frequency furnace to melt and alloy it. Use argon to quickly press the molten alloy from the quartz tube onto the high-speed rotating water-cooled copper roller and throw it out, so that the alloy is ~10 6 Cool at a rate of K / s to obtain alloy strips with a thickness of 2 μm and a width of 5 mm. Grind the strip-shaped alloy in an agate mortar and sieve, and take the part with a particle size of 100-200 mesh for aluminum extraction and activation.

Embodiment 2

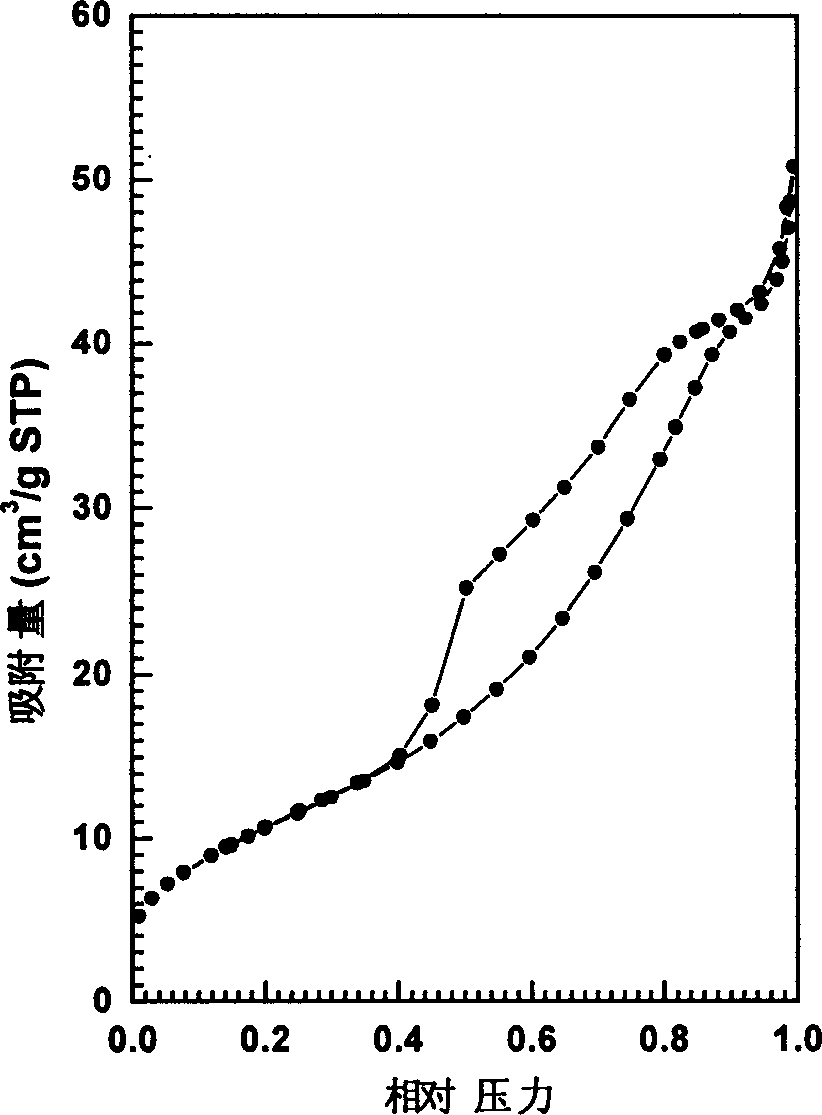

[0021] Embodiment 2: the preparation of quenching framework Co catalyst (RQ Co)

[0022] Heat 100 mL of 6.0 M NaOH solution to 363 K, and then add 10.0 g of quenched Co-Al alloy in batches under slow magnetic stirring. After adding the alloy, continue to stir at this temperature for 1.0h, so that the aluminum in the alloy is fully extracted. The obtained black solid powder was washed with a large amount of distilled water to neutrality, the water was replaced with ethanol three times, and stored in ethanol for later use. Some characterization results of the catalyst are shown in Table 1.

Embodiment 3

[0023] Embodiment 3: the preparation of modified type quenching framework Co-M catalyst (RQ Co-M, M is Cr, Mn, Fe, Ni, Cu, Zn, Sn or Mo)

[0024] Add 10.0 g of quenched skeleton Co catalyst to 220 mL of CrCl at 303 K 3 Ethanol solution, MnCl 2 ethanol solution, FeCl 2 Ethanol solution, NiCl 2 ethanol solution, CuCl 2 Ethanol solution, ZnCl 2 Ethanol solution, SnCl 2 Ethanol solution or Na 2MoO 4 The aqueous solution was stirred for 60 min. After the reaction, wash 3 times with distilled water, then wash 3 times with ethanol, and store in ethanol. The addition amount of the additive is 0.10 g by weight of the metal element. Some characterization results of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com