High speed percision polishing device and polishing method with diamond film

A diamond film, precision polishing technology, applied in polishing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high heating temperature of polishing disc, large warping deformation of polishing disc, large temperature gradient, etc. The effect of small warpage deformation and small temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

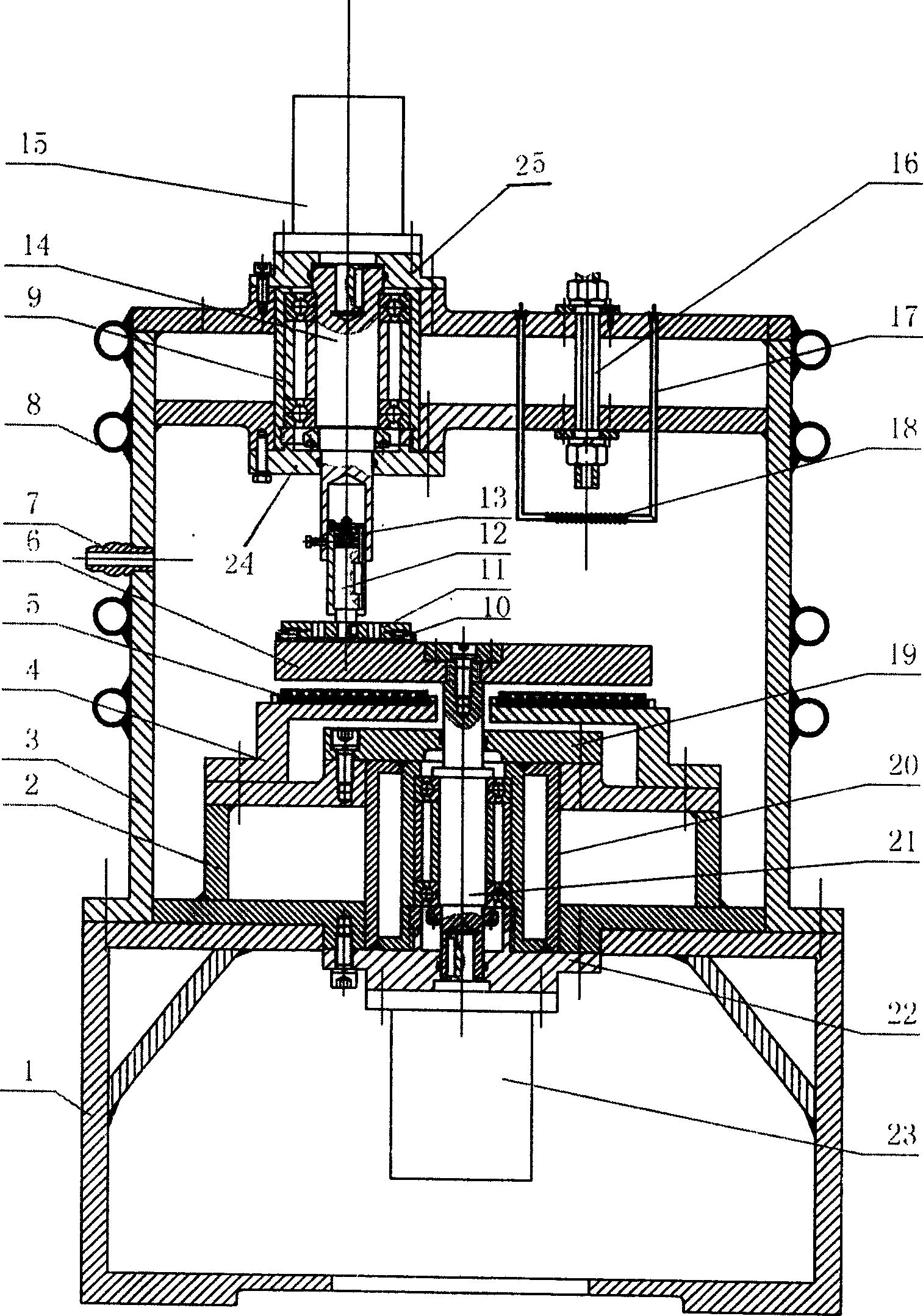

[0010] As shown in the figure, the structural scheme and working process of the present invention are further described in conjunction with examples.

[0011] A diamond film high-speed precision polishing device and polishing method, the polishing device includes a bed 1, a polishing disk drive device, a diamond film drive device, a vacuum polishing chamber cover 3 and a heater 5, and the polishing disk drive device is arranged on the vacuum polishing chamber cover 3, and are respectively fixed on the bed 1 by bolts. The vacuum polishing outer cover 3 is arranged on the bed 1, the diamond film driving device is fixed on the vacuum polishing outer cover 3 by bolts, and the electromagnetic heater 5 is arranged on the upper support 4 of the polishing disc driving device; Optical disc 6, flange plate 19, support body 20, polishing main shaft 21, fixed disc 22, speed-regulating motor 23, polishing disc 6 is fixed on the polishing main shaft 21 with screw by pressing plate, and poli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com