Fertilizer composition and its preparation

A composition and fertilizer technology, applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of large lignin, consumption, etc., and achieve the effect of high product quality, mature technology, and insect pest control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

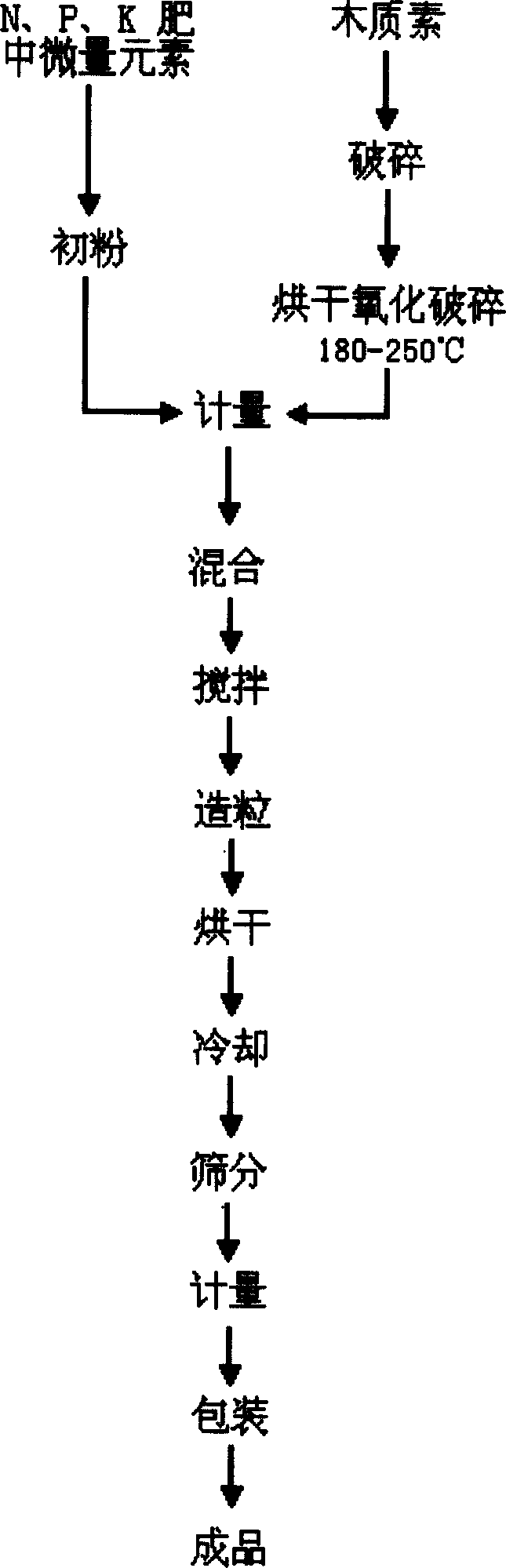

Method used

Image

Examples

Embodiment 1

[0060] Take the following components:

[0061] Lignin 3.06t

[0062] Urea 2.19t

[0063] Monoammonium phosphate 2.19t

[0064] Potassium sulfate 0.44t

[0065] Zinc acetate 0.87t

[0066] The lignin with a water content of 45-60% is crushed and sent to the dryer, and the temperature is raised to 180°C within half an hour, and then the lignin is linearly heated to 200°C within 30 minutes, and the temperature is raised after keeping for 40 minutes. The temperature of the lignin is raised linearly to 250° C. within 70 minutes, kept for 1.5 hours, the moisture content of the lignin is 8%, and the drying is finished. (heating curve see Figure 4 )

[0067] Urea, monoammonium phosphate and potassium sulfate enter the crusher for crushing; they are mixed with lignin after metering, stirred and transported to the granulator for granulation, and the finished product is dried, cooled and then sieved to obtain the final product.

[0068] Indicator name

Embodiment 2

[0070] Take the following components:

[0071] Lignin 6t

[0072] Urea 3.45t

[0073] Monoammonium phosphate 3.75t

[0076] Crumble the lignin with a water content of 45-60%, send it to the dryer, control the temperature of the lignin to 180°C within half an hour, and then linearly increase the temperature of the lignin to 200°C within 30 minutes, and keep it for 30 After 10 minutes, continue to raise the temperature. After 80 minutes, the lignin temperature rises linearly to 250° C., and keeps for 4 hours. The water content of the lignin is 6%, and the drying ends. (heating curve see Figure 5 )

[0077] Urea, monoammonium phosphate, potassium sulfate and iron salt enter the crusher for crushing; they are mixed with lignin after metering, stirred and transported to the granulator for granulation, and the finished product is dried, cooled and then sieved to obtain the final product.

Embodiment 3

[0079] Take the following components:

[0080] Lignin 4.05t

[0081] Urea 1.8t

[0082] Monoammonium phosphate 1.8t

[0083] Potassium sulfate 0.45t

[0084] Manganese sulfate 0.9t

[0085] The lignin with a water content of 45-60% is crushed and sent to the dryer, and the temperature is raised to 180°C within half an hour, and then to 200°C within 30 minutes, and the temperature is raised after 36 minutes, and after 73 minutes, The temperature of lignin is raised linearly to 250°C and kept for 3.5 hours, the moisture content of lignin is 7%, and the drying is finished. (heating curve see Figure 6 )

[0086] Urea, monoammonium phosphate, potassium sulfate and manganese salt enter the crusher for crushing; they are mixed with lignin after metering, stirred and transported to the granulator for granulation, and the finished product is dried, cooled and then sieved to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com