Burning method and its device for burning irregular low ash smelting point fuel

A kind of ash melting point, irregular technology, applied in the fields of combustion method and equipment, combustion method and equipment for burning solid waste and biomass fuel, can solve the problems of large water content and large particle size, and achieve good emission, Effect of small temperature fluctuation and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

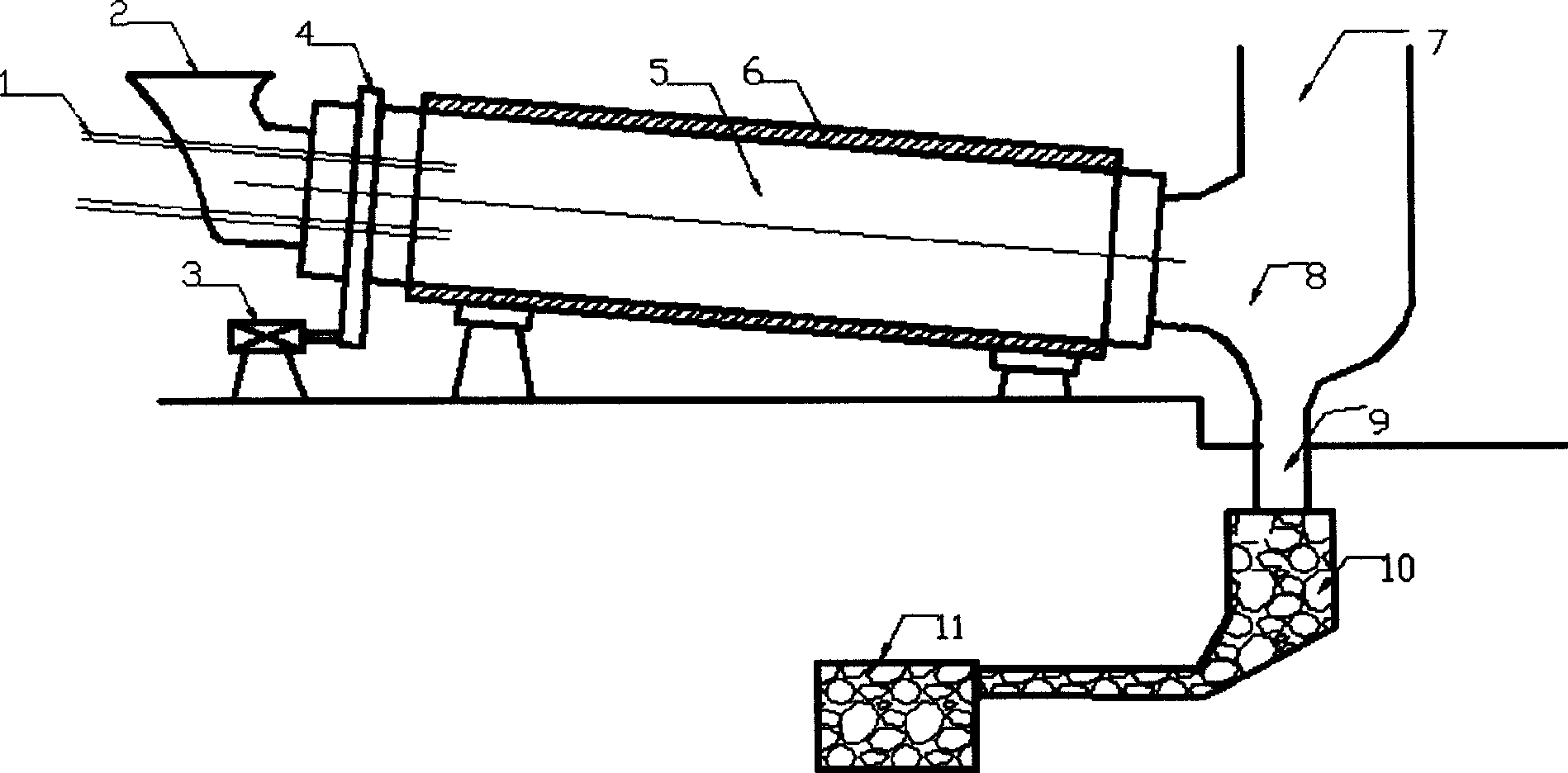

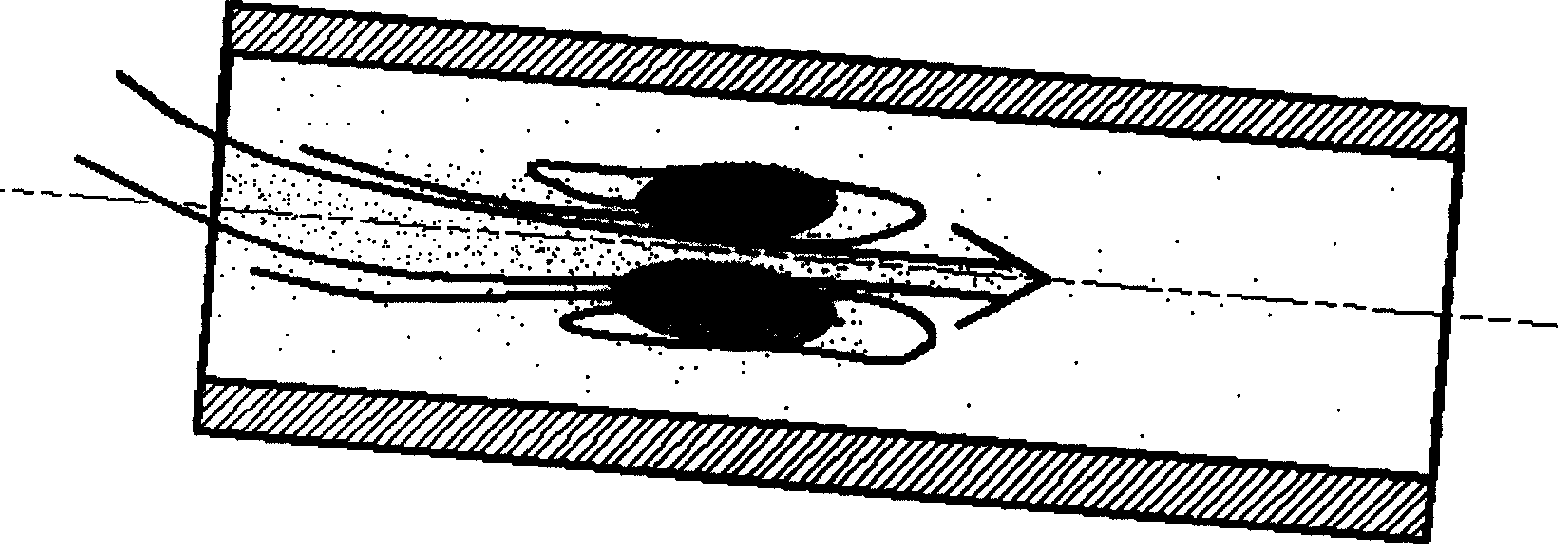

[0017] The working principle, structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The working principle of the present invention is as follows: In the present invention, a horizontal inclined rotating combustion chamber 5 is adopted, and a heat insulating layer 6 is arranged around the combustion chamber. After the normal operation of the combustion equipment, a high temperature zone is maintained in the combustion chamber. Since there is no need to arrange water-cooled walls in the furnace to absorb heat like chain furnaces and fluidized bed boilers, the heat balance equation can be expressed as:

[0019] Q r,w +Q r,a +Q r,k =Q 1 +Q 2 +Q 3 +Q 4 +Q 5

[0020] Among them: Q r,w : Calorific value of fuel kJ / h;

[0021] Q r,a Calorific value of auxiliary fuel kJ / h;

[0022] Q r,k Calorific value of combustion air kJ / h;

[0023] Q 1 The heat carried away b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com