Full light wave converter based on laser four wave mixing effect

A wavelength converter and four-wave mixing technology, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as high cost and complex device structure, and achieve low cost, adjustable conversion wavelength, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

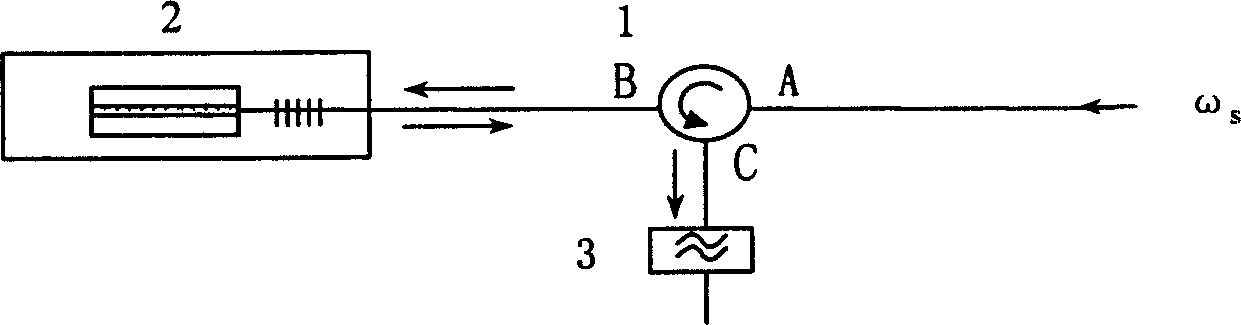

[0017] Embodiment one: fiber grating external cavity semiconductor laser as an all-optical wavelength conversion device ( figure 1 )

[0018] The signal light is input from the A port of the circulator 1, and injected into the fiber grating external cavity semiconductor laser through the B port. The signal light (frequency ωs) in the active medium of the laser produces a four-wave mixing effect with the pumping laser (frequency ωp) to generate a conjugate wave (frequency 2ωp-ωs) as the converted output signal.

[0019] The converted output signal enters the B port of circulator 1, and then is coupled out by the C port. Using a fiber optic circulator for coupling between the signal and the semiconductor laser chip can improve the coupling efficiency, reduce the influence of the converted signal light and the light source feedback light on the signal light source, and increase the output power of the converted signal.

[0020] The converted output signal coupled from the C por...

Embodiment 2

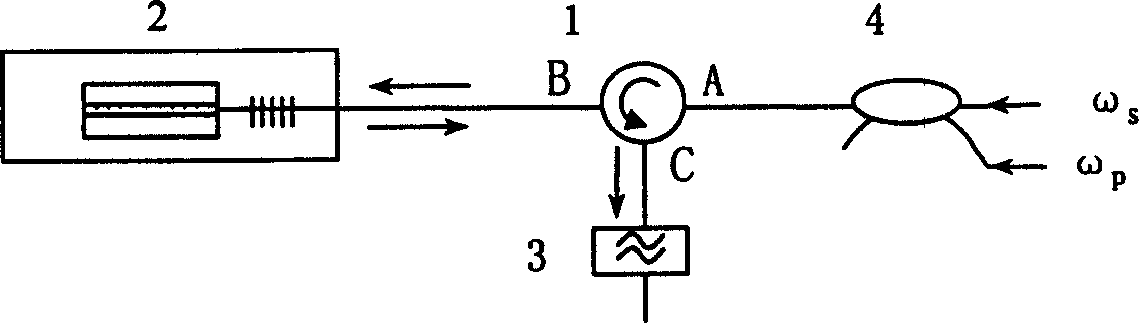

[0021] Embodiment two: fiber grating external cavity semiconductor laser is used as an all-optical wavelength conversion device for converting an output light source ( figure 2 )

[0022] The signal light (frequency ωs) and continuous pump light (frequency ωp) enter the A port input of the circulator 1 through the coupler 4, and are injected into the fiber grating external cavity semiconductor laser 2 through the B port. The working current of the laser 2 is adjusted, and the laser 2 is in a critical excitation state (not yet excited) under the condition that only continuous pumping light is injected. When a "1" signal is injected, the signal light and the pump light will generate a conjugate wave (frequency is 2ωp-ωs), and the excitation frequency of the fiber grating external cavity semiconductor laser 2 is selected to be 2ωp-ωs, then the conjugate wave will be Quite an "injection seed" to excite the laser 2 as the converted signal light. Because the frequency of the conj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com