Organic field effect transistor orientation layer and its preparing method and use

An orientation layer, organic field technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as breakdown of OFETs, surface unevenness of rayon, and effects of OFET switching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

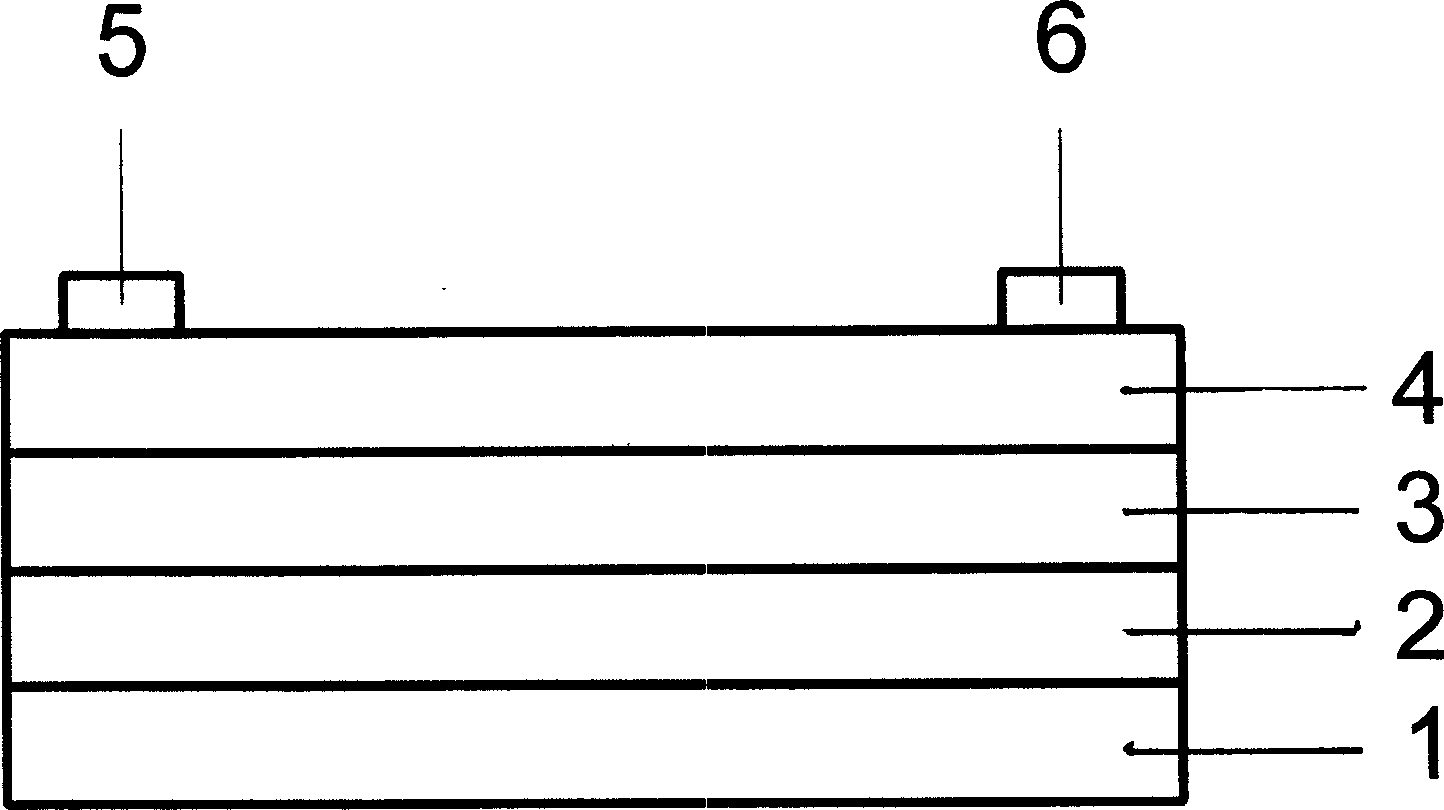

[0037] The polyimide (PI) we used was RN-1333 type PI provided by Nissan Chemical Industry at a concentration of 5 wt%. We dilute it to 2wt% when using it. First form an ITO electrode on a clean glass substrate, and then use photolithography to form a gate pattern on the substrate. After the polyimide (PI) solution is dispersed by ultrasonic waves for 20-30 minutes, it is spin-coated on On the ITO glass substrate, control a certain spin-coating speed and time. Then place the coated substrate on a hot table at 100°C to dry for 5 minutes for pre-baking treatment, and then place it in a clean oven at 250°C for 1 hour to perform film hardening treatment. Thereafter, it was naturally cooled to room temperature.

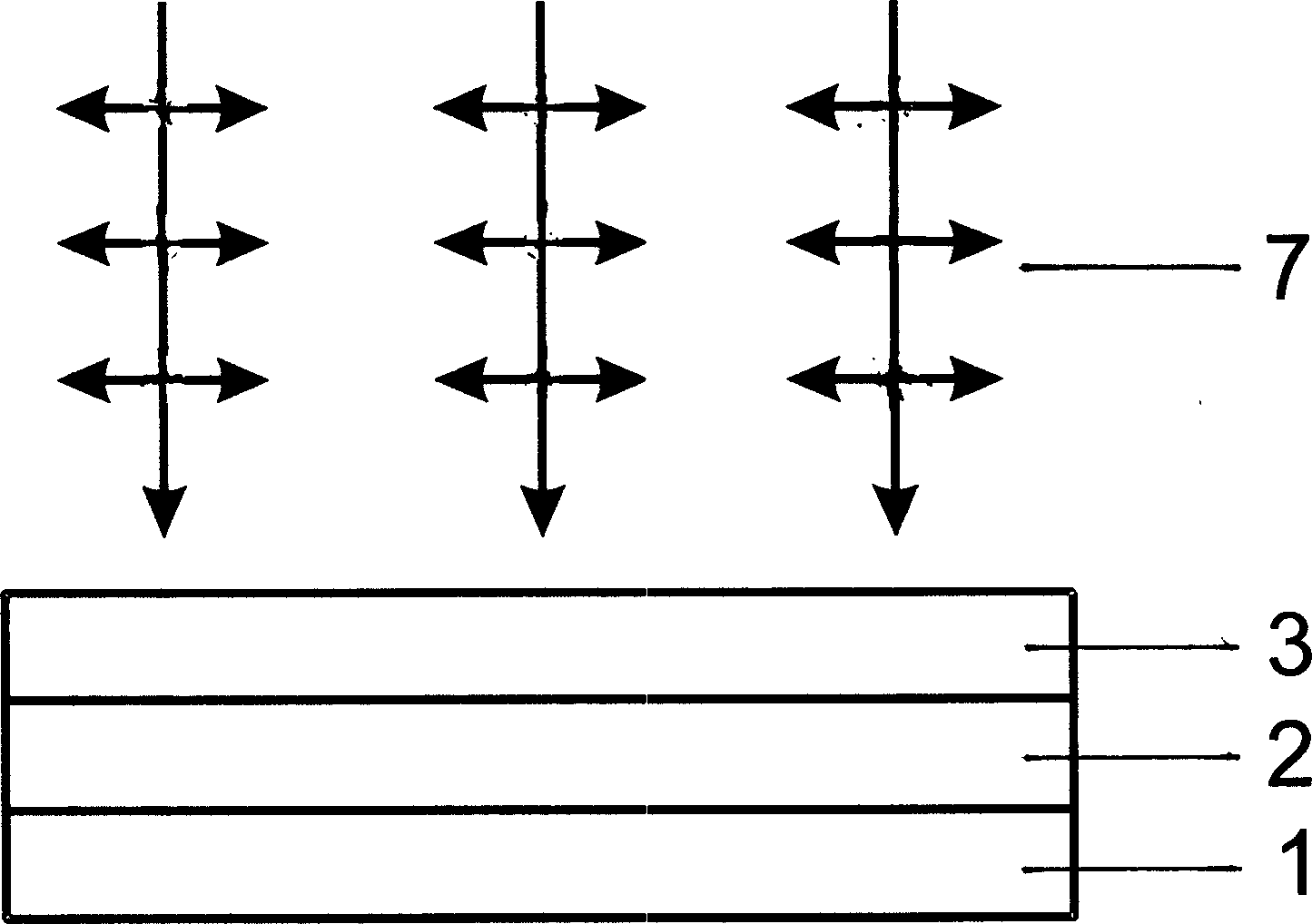

[0038] Then, with a power density of 10mW / cm 2 The ultra-high pressure mercury lamp directly irradiates linearly polarized ultraviolet light with a spectral peak of about 365nm onto the above-mentioned orientation insulating layer vertically, as shown in the attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com