Variable frequency driving device of 3KV-10KV middle-high voltage multi-level three-phase AC motor

A three-phase AC, variable frequency drive technology, applied in the direction of DC motor speed/torque control, AC power input conversion to AC power output, AC power input conversion to DC power output, etc., can solve the increase in manufacturing difficulty and cannot reach 6KV The output and wiring are complex and other problems, so as to improve reliability, increase flexibility and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] To achieve the above object, the present invention adopts the following scheme:

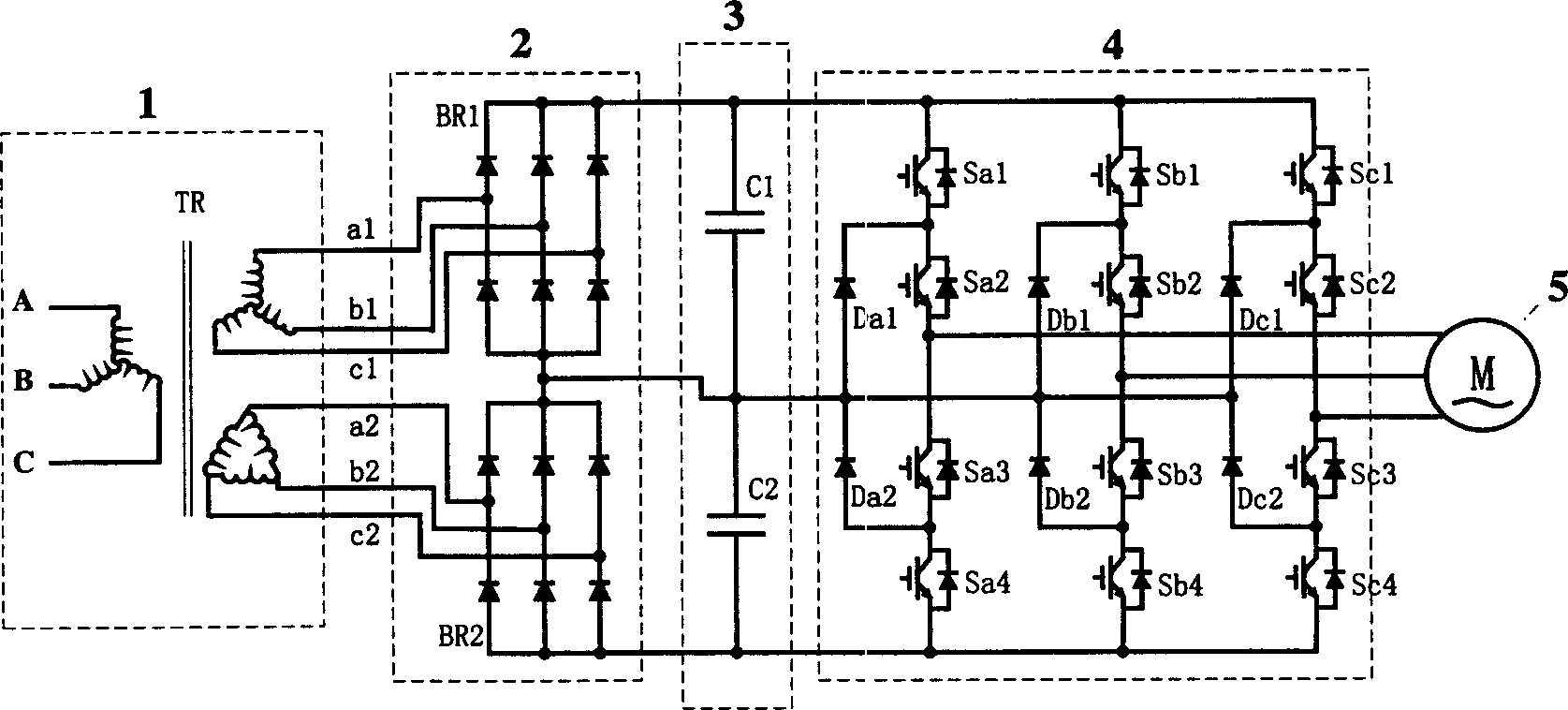

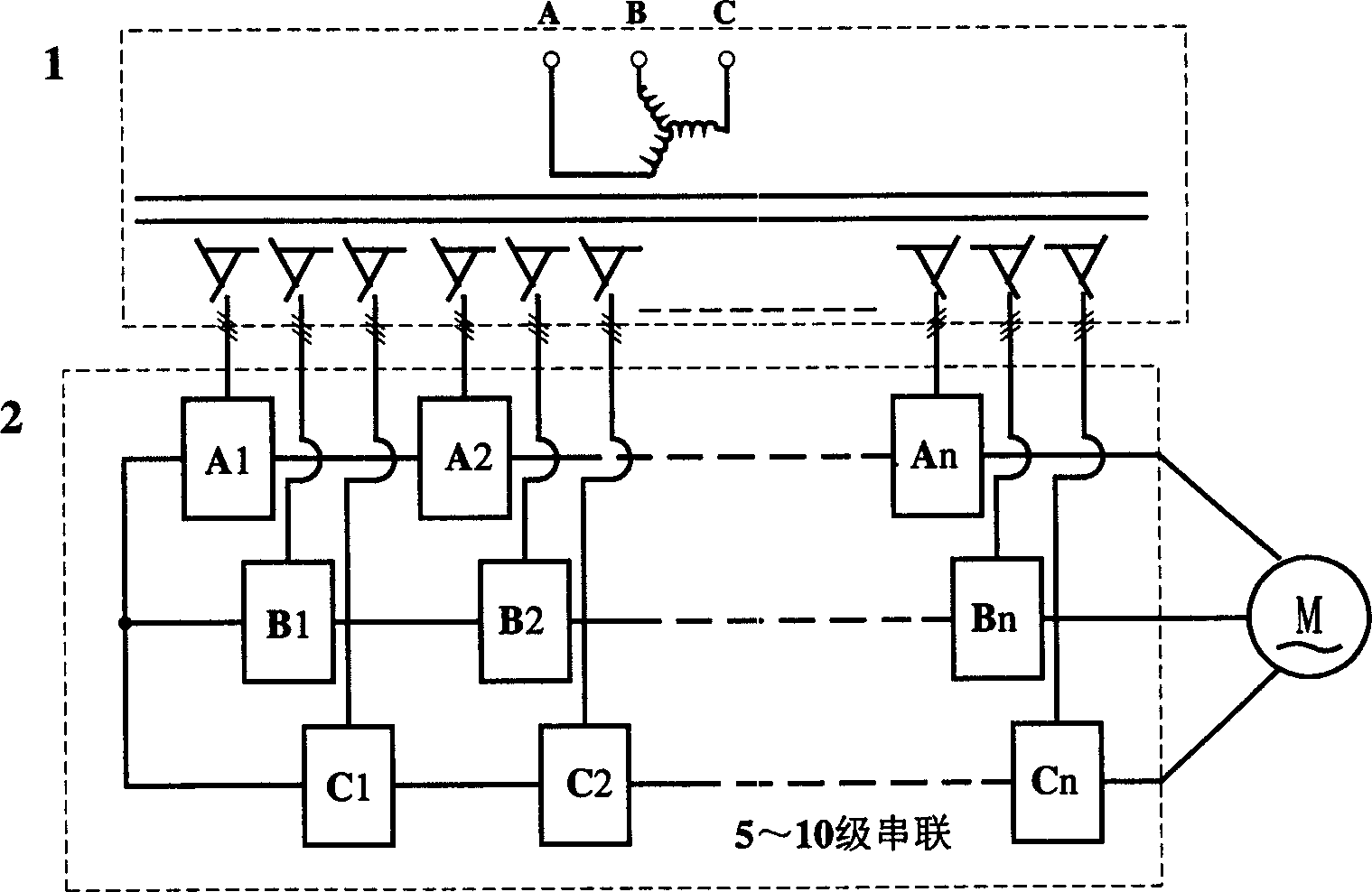

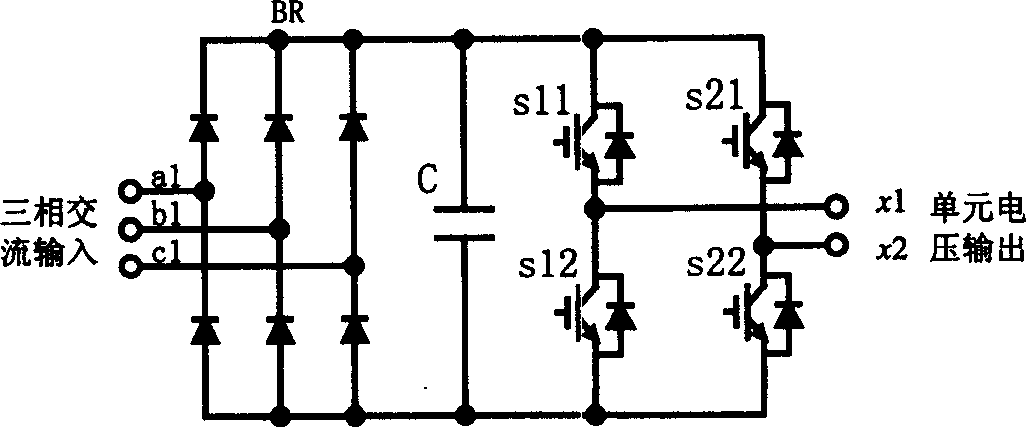

[0041] The present invention is composed of multi-winding secondary side phase-shift isolation transformer, a plurality of AC-DC-AC three-level H-bridge power conversion units (hereinafter referred to as three-level H-bridge power units) and an all-digital controller, see image 3 shown. The multi-winding secondary phase-shifting isolation transformer (hereinafter referred to as phase-shifting isolation transformer), its secondary windings are multiple sets of three-phase windings, and the output line voltage phases of each three sets of windings are sequentially shifted through the same phase angle; each output three-phase The windings are connected to a three-level H-bridge power unit, and the outputs of the three-level H-bridge power units connected to the three-phase windings with different phase shifts are connected in series to form a Y shape.

[0042] The three-level H-bridge power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com