Non-gelatinous capsule film compositions and capsules using the same

一种组合物、胶凝的技术,应用在非有效成分的医用配制品、胶囊输送、微型胶囊等方向,能够解决降低存储稳定性、胶囊壳龟裂或软化、胶囊易碎吸湿性/释放性等问题,达到高强度、易于崩解、佳存储稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The capsule shell components shown in Table 1 were mixed to prepare a non-gelled capsule shell composition. MCTs (medium chain triglycerides) shown in Table 1 were prepared as the contents of the capsules.

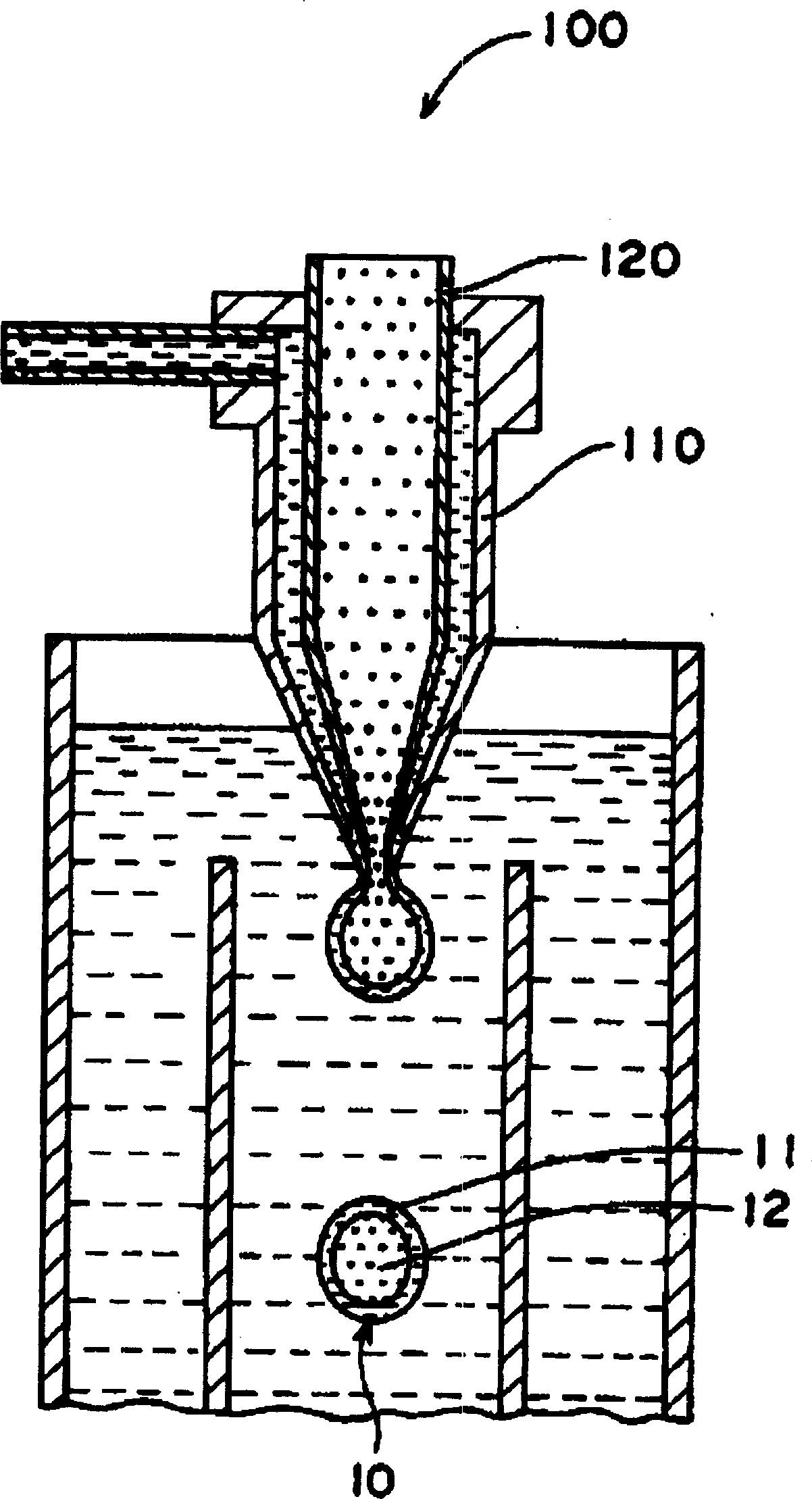

[0058] The shell composition and contents are used as figure 1 The shown machine 100 for preparing seamless capsules prepares the capsule 10 of the present invention having a double structure in which the contents 12 are contained in the capsule shell 11 according to the following method. The non-gelled capsule shell composition of the present invention heated to 70° C. is sprayed through the outer nozzle of a concentric double nozzle and simultaneously sprays the contents through its inner nozzle, thereby forming a dual and then release the jet into a cooled solution (vegetable oil cooled to a temperature not higher than 20° C.), thereby obtaining the seamless capsule of the present invention. After drying the resulting capsules in a forced air circulation oven a...

Embodiment 2

[0078] The same method as described in Example 1 was used to prepare the seamless capsule of the present invention, except that the capsule shell and content formulations shown in Table 2 were used. The obtained capsule 10 had a particle diameter φ of 2 mm and a capsule shell thickness of 85 μm.

[0079] Table 2

[0080] Composition Quantity

[0081] (shell)

[0082] Matrix:

[0083] Soluble starch (Stabilose TA-13)** 15.2% by weight

[0084] Gelling agent:

[0085] κ-Carrageenan 2.3% by weight

[0086] Locust bean gum 0.1% by weight

[0087] Shell Enhancer:

[0088] Glycerin 4.5% by weight

[0089] Gelling aids:

[0090] Potassium chloride 0.4% by weight

[0091] Purified water 77.5% by weight

[0092] 22.5% solids

[0093] (inclusions)

[0094] MCT (Medium Chain Triglycerides) 100% by weight

[0095] **: Commercially available from Matsutani Chemical Industry Co., Ltd.; average molecular weight = 20,000 to 30,000; DE = about 1.

Embodiment 3

[0097] The same method as described in Example 1 was used to prepare the seamless capsule of the present invention, except that the capsule shell and content formulations shown in Table 3 were used. The obtained capsule 10 had a particle diameter φ of 2 mm and a capsule shell thickness of 85 μm.

[0098] table 3

[0099] Composition Quantity

[0100] (shell)

[0101] Matrix:

[0102] Soluble starch (Stabilose TA-13)** 14.1% by weight

[0103] Gelling agent:

[0104] Furcellan 2.3% by weight

[0105] Locust bean gum 0.1% by weight

[0106] Shell Enhancer:

[0107] Glycerin 5.6% by weight

[0108] Gelling aids:

[0109] Potassium chloride 0.4% by weight

[0110] Purified water 77.5% by weight

[0111] 22.5% solids

[0112] (inclusions)

[0113] MCT (Medium Chain Triglycerides) 100% by weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com