Method for preparing nano metal and bimetal hollow ball

A nano-metal and bi-metal technology, applied in the nano field, can solve the problems of high cost, high energy consumption, long preparation cycle, etc., and achieve the effect of saving materials and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

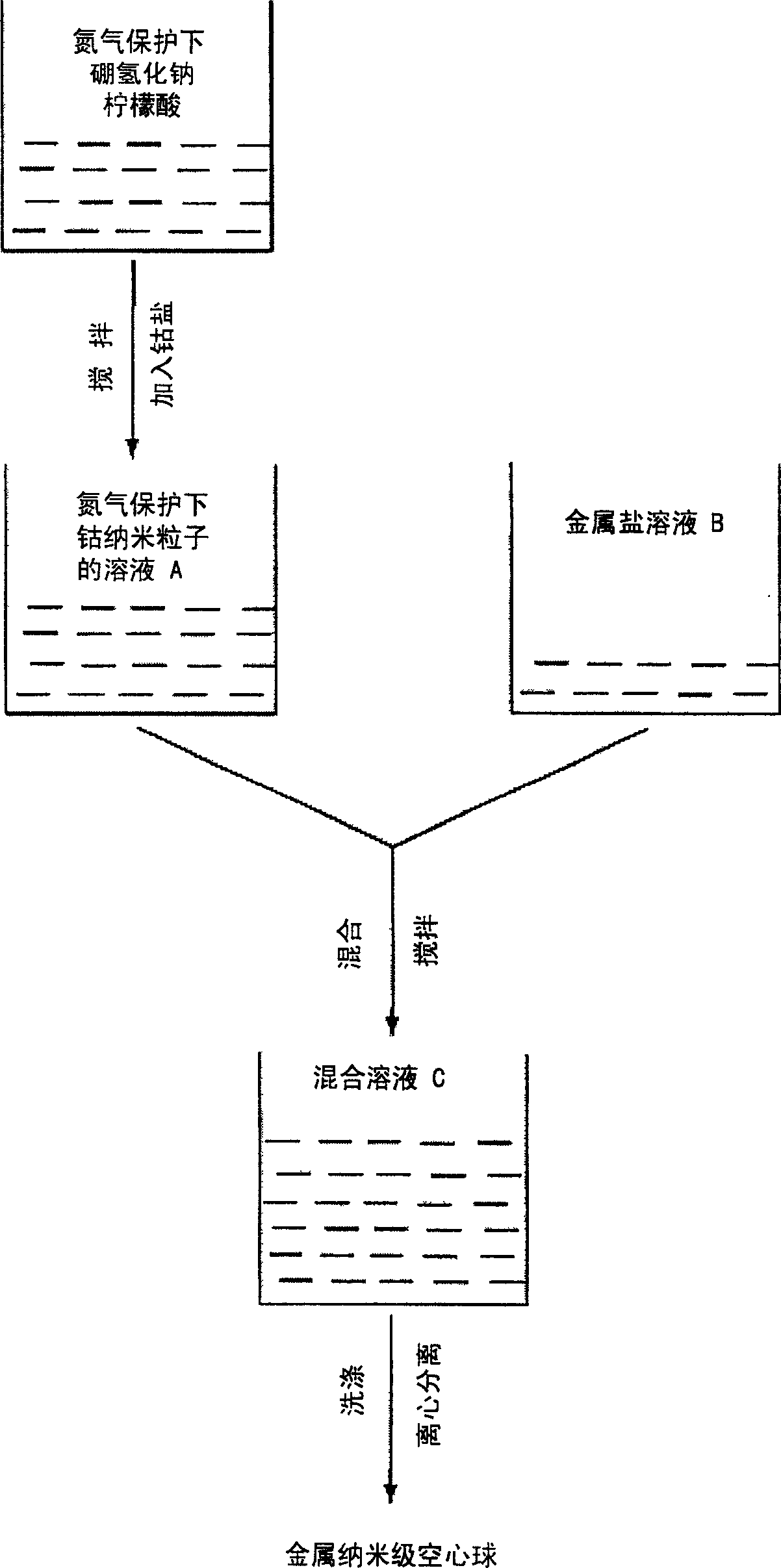

Method used

Image

Examples

Embodiment 1

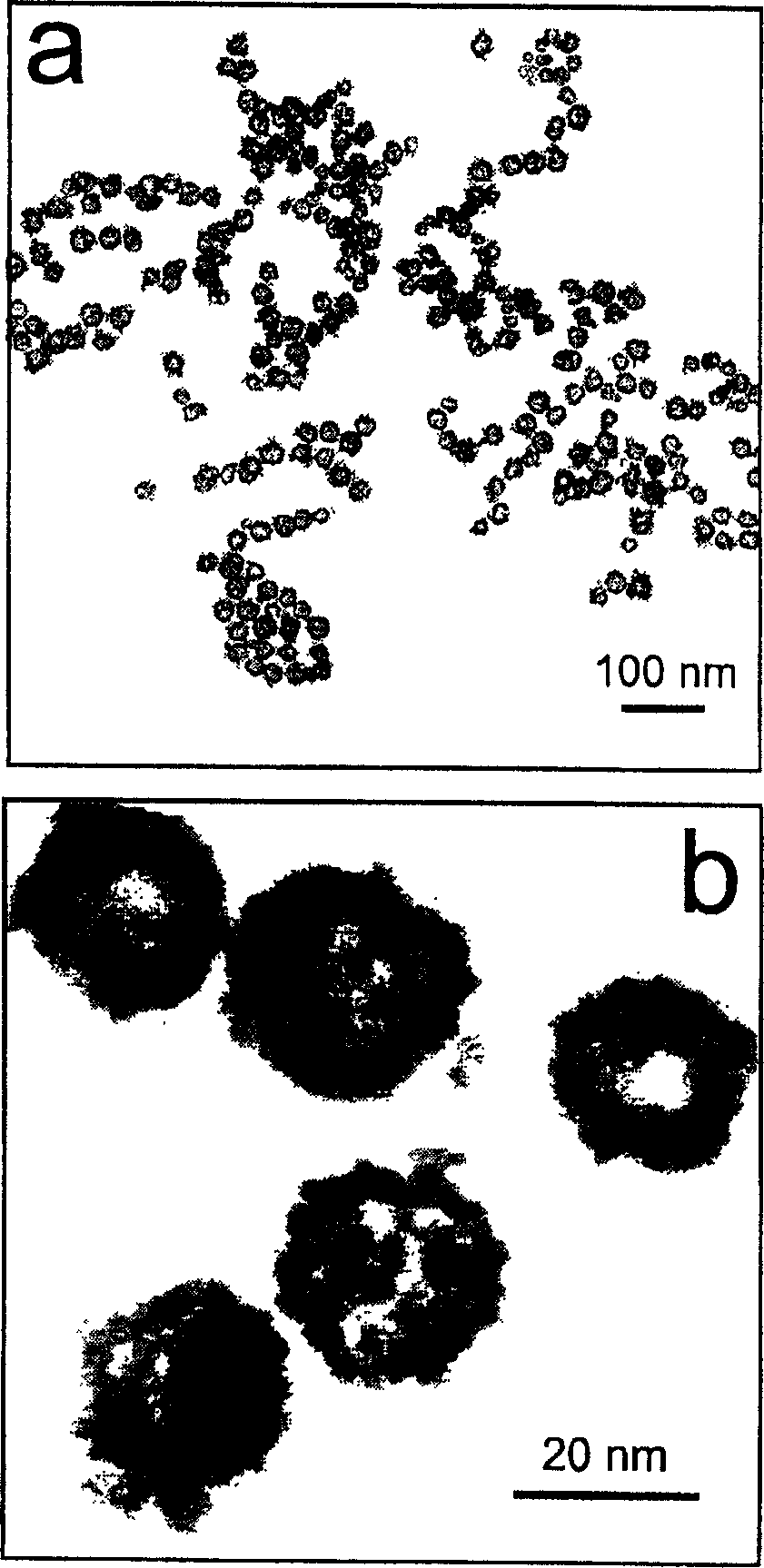

[0035] Embodiment 1: At first, the sodium borohydride of 0.01513 grams is added in the 0.4mM citric acid solution of 100 milliliters under the protection of nitrogen, at this moment, there will be bubble (hydrogen) to generate in the solution. Then add the 0.4M cobalt chloride solution of 100 microliters, while adding the cobalt chloride solution, the solution becomes black at once, namely cobalt chloride is reduced by sodium borohydride to generate cobalt nanoparticles, and the obtained 100 ml The cobalt particle solution was rapidly mixed with the 1 mM chloroplatinic acid solution (solution B), that is, the reaction solution A was quickly poured into the solution B under stirring and mixed.

[0036] (1)

[0037] According to the stoichiometric ratio shown in Equation 1 above, the complete reaction of the reaction solution A and the chloroplatinic acid solution B is controlled. Cobalt particles and chloroplatinic acid will undergo a rapid displac...

Embodiment 2-4

[0039]By the same procedure in Example 1, according to the stoichiometric relationship, reaction solution A is mixed with solution B (auric chloride solution, palladium chloride solution and rhodium chloride solution) respectively, and nanoscale gold, palladium and rhodium can be obtained hollow ball.

Embodiment 5-7

[0041] According to the same procedure in Example 1, the mixed solution (solution B) of solution A and bimetallic (platinum, platinum-palladium and gold-palladium) salts can be mixed to make nano-scale bimetallic (platinum, platinum-palladium and gold-palladium) hollow ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com