Waste water and coke powder mixed solid fuel and its preparing method

A technology of solid fuel and coke powder, which is applied in the field of waste water coke powder mixed solid fuel and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

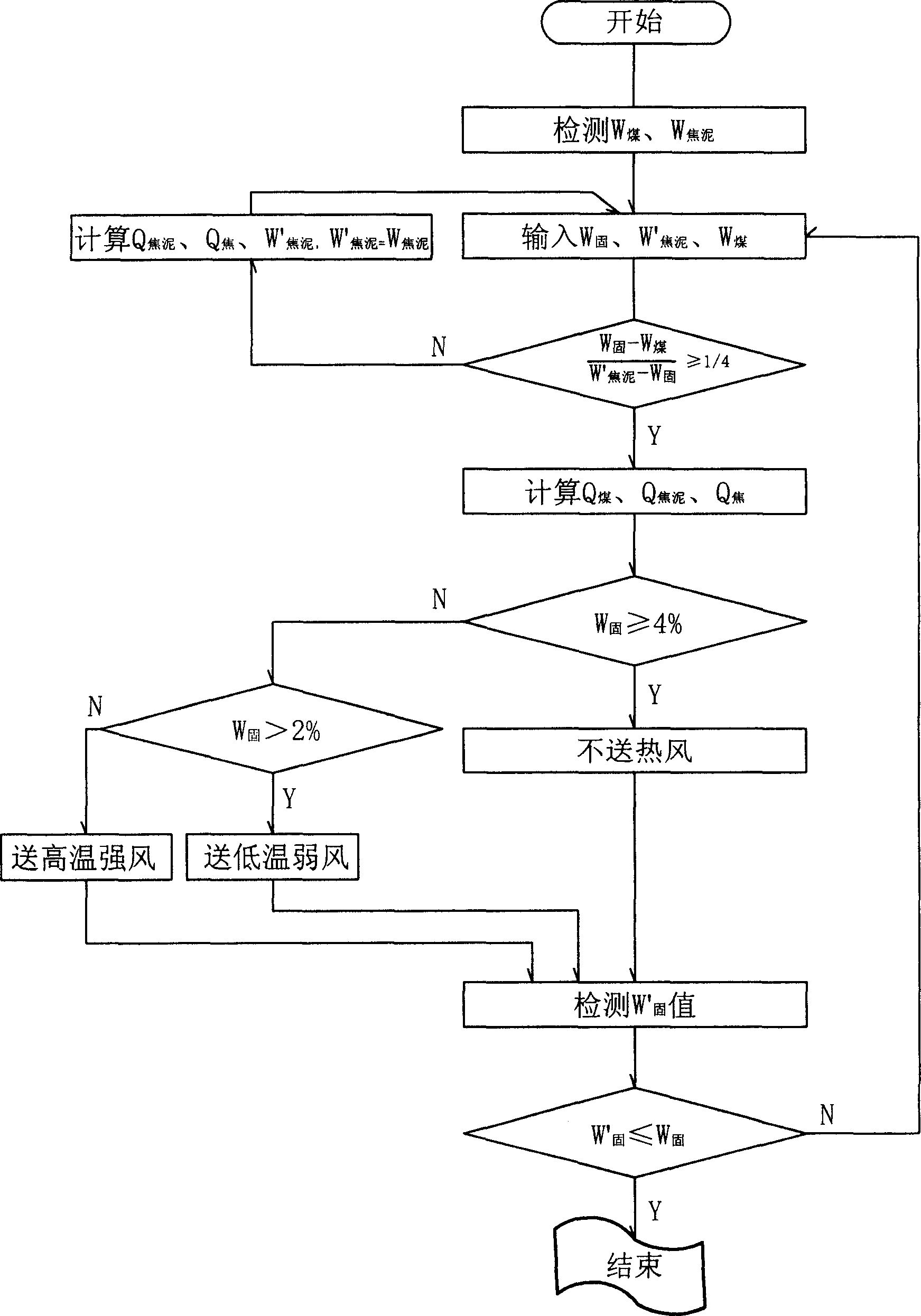

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Add coal powder to the wastewater coke powder mixture after filtration and adsorption treatment of industrial wastewater and urban sewage to make wastewater coke powder mixed with solid fuel, which is used as fuel for circulating fluidized bed boilers.

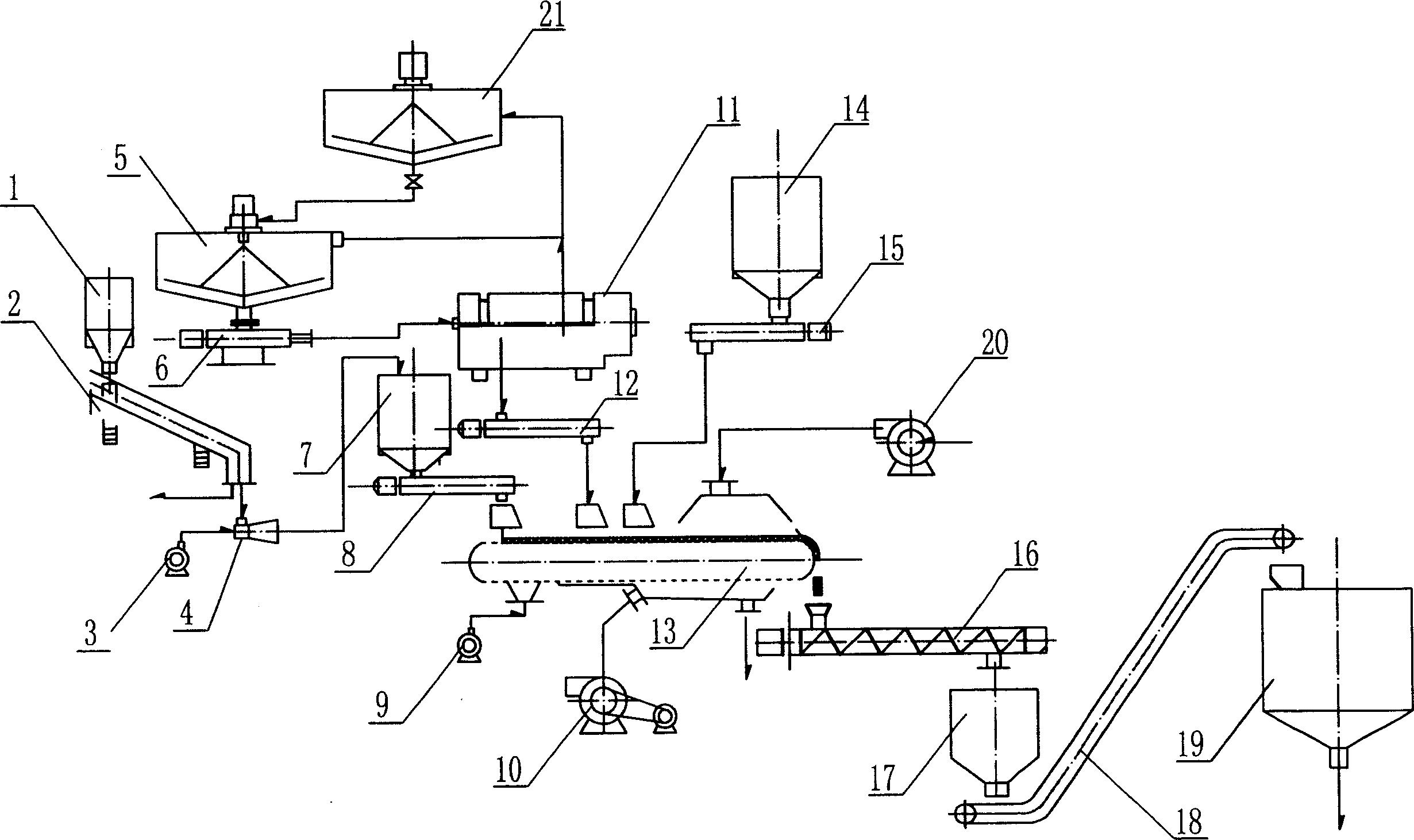

[0057] (1) Making waste water coke powder mixed with solid fuel

[0058] Use low-temperature coke powder and silica coke powder to treat industrial wastewater and municipal sewage. Transport the wastewater coke powder mixture produced by filtration and adsorption treatment of industrial wastewater and urban sewage to the concentration tank 5 for sedimentation and dehydration, so that the water content of the wastewater coke powder mixture is reduced to 焦泥 = 30%. Circulating fluidized bed boiler requires fuel moisture content W 固 =15%, the selected bituminous coal powder, its water content W 煤 = 5.1%.

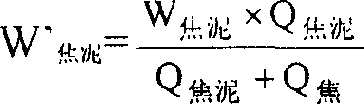

[0059] Calculated:

[0060] There is no need to add filter coke powder, and because W 固 =15%>4% does...

Embodiment 2

[0074] Example 2: Add coal powder to the wastewater coke powder mixture after filtration and adsorption treatment of industrial wastewater and urban sewage to prepare wastewater coke powder mixed with solid fuel, which is used as fuel for the grate boiler.

[0075] (1), preparation of waste water coke powder mixed solid fuel

[0076] Use lignite coke powder to treat industrial wastewater and municipal sewage. Transport the wastewater coke powder mixture produced by filtration and adsorption treatment of industrial wastewater and urban sewage to the concentration tank 5 for sedimentation and dehydration, so that the water content of the wastewater coke powder mixture is reduced to 固 =14%, through horizontal screw type sedimentation centrifuge 13 to the waste water coke powder mixture after the sedimentation dehydration is further dehydrated to W 焦泥 =22%, select lignite powder, its water content W 煤 = 2%.

[0077] Calculated:

[0078] There is no need to add filter coke powd...

Embodiment 3

[0091] Example 3: Add coal powder to the wastewater coke powder mixture after filtration and adsorption treatment of industrial wastewater and urban sewage to make wastewater coke powder mixed with solid fuel, which is used as fuel for pulverized coal boilers.

[0092] (1), preparation of waste water coke powder mixed solid fuel

[0093] Use metallurgical coke powder and gas coal coke powder to treat industrial wastewater and urban sewage. Transport the wastewater coke powder mixture after filtration and adsorption treatment of industrial wastewater and urban sewage to the concentration tank 5 for sedimentation and dehydration, so that the water content of the wastewater coke powder mixture is reduced to 固 ≤4%, the waste water coke powder mixture after sedimentation and dehydration is further dehydrated through the horizontal screw type sedimentation centrifugal dehydrator 13; its water content W 焦泥 =22%, choose bituminous coal powder, its water content W 煤 = 2%

[0094] Cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com