On-line silk screen printing apparatus for paper production

A technology of screen printing and screen printing device, which is applied in the field of online screen printing equipment for paper production, can solve the problems of high equipment investment, small curing area, long distance between production lines, etc., and achieves good equipment sealing and stable printed product quality. , The effect of less on-site occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

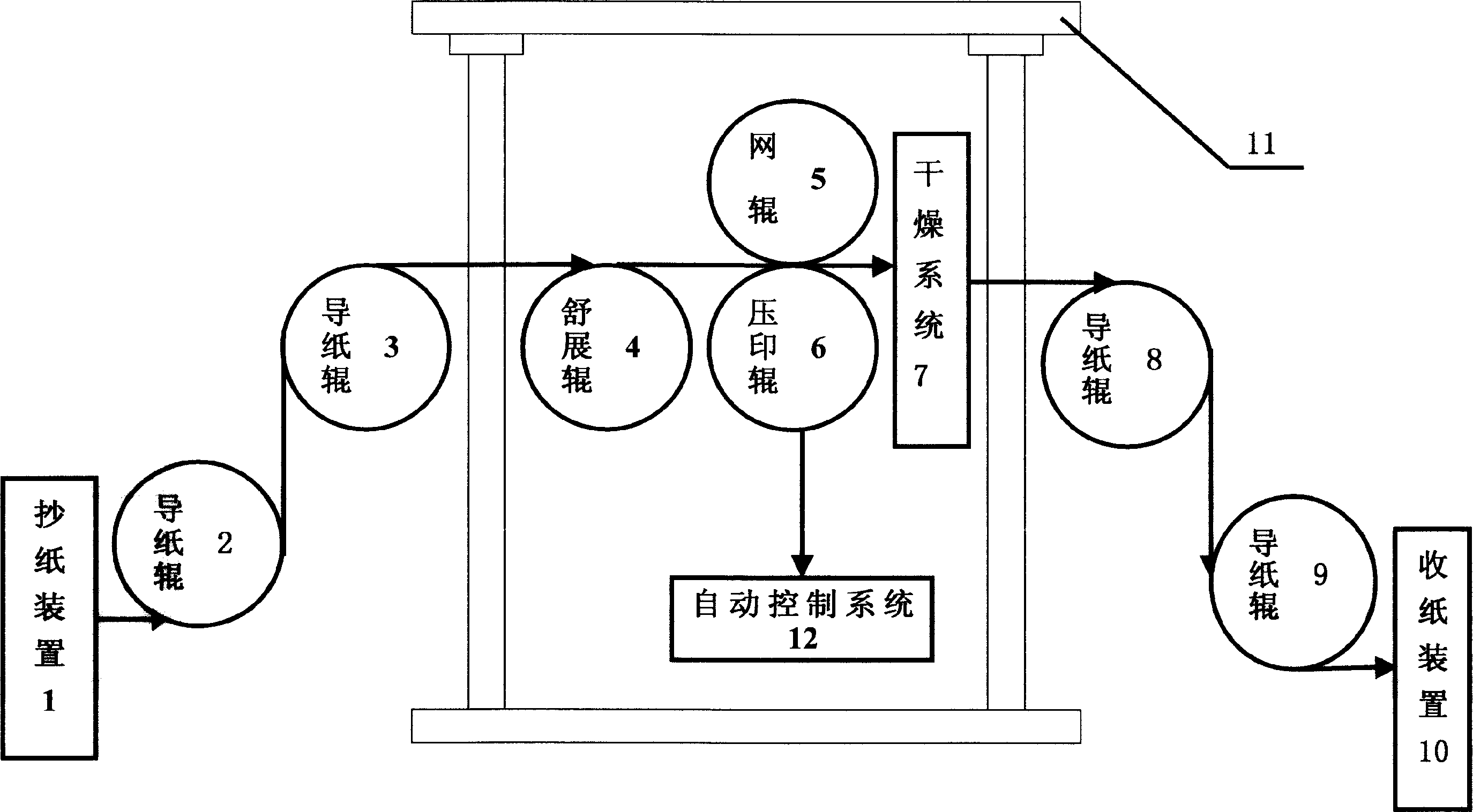

[0027] The present invention unifies the screen printing device and the papermaking device into a whole, and provides integral transmission for the screen printing machine and the paper machine through the traction equipment, so that the screen printing machine and the paper machine can work synchronously, and electrical control, data processing Use one system together with controls such as moisture detection.

[0028] Referring to the accompanying drawings, the paper machine of the present invention consists of a paper making device 1 and a paper delivery device 10 in two parts. A screen printing device is arranged between the papermaking device 1 and the papermaking device 1; the screen printing device includes: a printing automatic control system 12 and a screen roll 5, a spreader roll 4 positioned at the input end of the screen roll 5 after the paper guide roll 3, The embossing roller 6 arranged under the mesh roller 5 and parallel to it is arranged at the output end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com