Size-uniform agarose gel microball and its preparing method

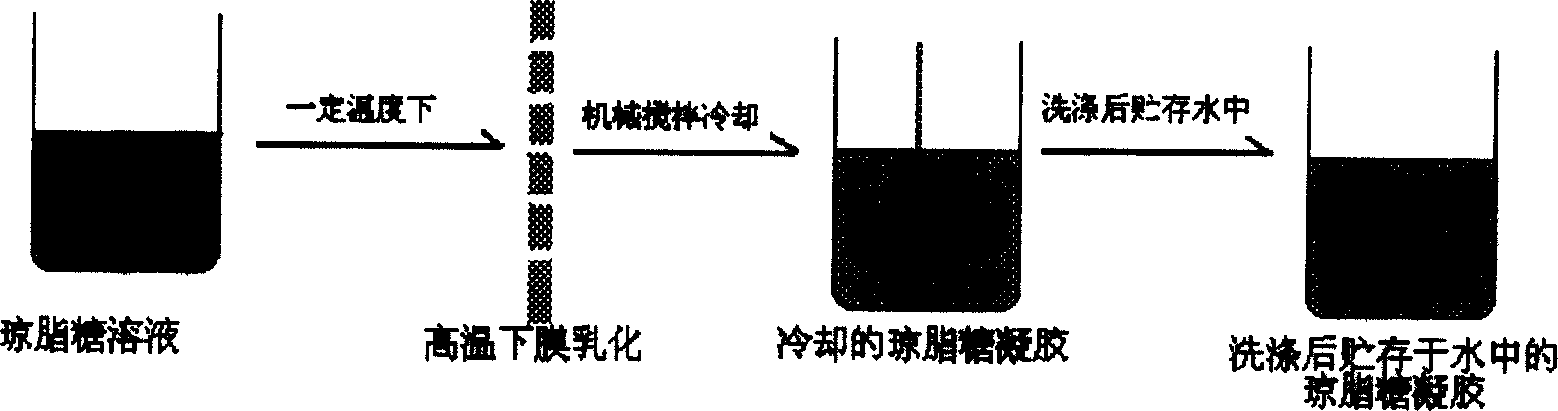

A technology of agarose gel and agarose, which is applied in the field of biochemical separation of bioengineering, can solve the problems of inhomogeneous particle size of agarose gel microspheres, large pressure changes, and poor separation effect, so as to avoid recognition and immune rejection , The pressure is stable and uniform, and the effect of column packing is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

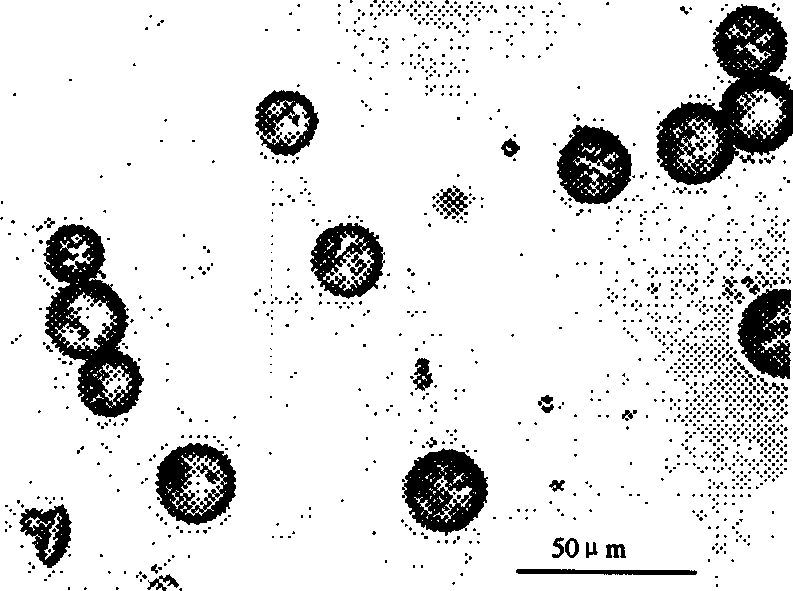

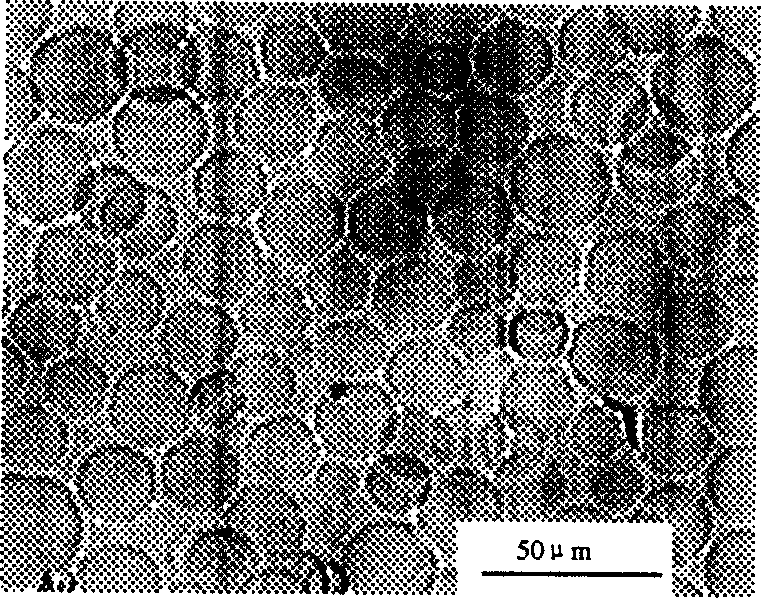

[0037]The hydrophobic membrane with a pore size of 5.7 μm is immersed in a lipophilic substance to fully wet the porous membrane to ensure that the hydrophobic chains on the membrane are completely stretched. Accurately weigh a certain amount of agarose and a certain amount of NaCl and add it to a certain amount of water, so that the concentration of the agarose is 4%, and the concentration of NaCl is 0.9%, and it is fully dissolved under heating conditions, and the solution is kept constant. The temperature is reserved. Add the oil-soluble emulsifier into 200ml of liquid paraffin, stir until completely dissolved and heat to 50°C as the oil phase. Quickly transfer about 6.0g of the water phase into the membrane emulsification device that has been preheated to 50°C in the oil phase while it is hot, and press it into the oil phase through a hydrophobic microporous membrane with uniform pore size under constant pressure to obtain W / O type emulsion; after the emulsification is co...

Embodiment 2

[0041] The hydrophobic membranes with pore diameters of 4.7 μm, 5.7 μm, 13 μm, and 19.6 μm were soaked in lipophilic substances, so that the porous membranes were fully wet to ensure that the hydrophobic chains on the membranes were completely stretched. Accurately weigh a certain amount of agarose and a certain amount of NaCl and add it to a certain amount of water, so that the concentration of the agarose is 4%, and the concentration of NaCl is 0.9%, and it is fully dissolved under heating conditions, and the solution is kept constant. The temperature is reserved. Add the oil-soluble emulsifier into 200ml of liquid paraffin, stir until completely dissolved and heat to 50°C as the oil phase. Quickly transfer about 6.0g of the water phase into the membrane emulsification device that has been preheated to 50°C in the oil phase while it is hot, and press it into the oil phase through a hydrophobic microporous membrane with uniform pore size under constant pressure respectively. ...

Embodiment 3

[0043] The hydrophobic membrane with a pore size of 4.7 μm is immersed in a lipophilic substance to fully wet the porous membrane to ensure that the hydrophobic chains on the membrane are completely stretched. Accurately weigh a certain amount of agarose and a certain amount of NaCl and add them to a certain amount of water so that the concentrations of the agarose are 2%, 4%, 6% and 8%, respectively, and the concentration of NaCl is 0.9%. Make it fully dissolved, and keep the solution at a certain temperature for later use. Add the oil-soluble emulsifier into 200ml of liquid paraffin, stir until completely dissolved and heat to a certain temperature as the oil phase. Quickly transfer about 6.0g of the water phase into the membrane emulsification device that has been preheated to the required temperature in the oil phase, and press it into the oil phase through a hydrophobic microporous membrane with uniform pore size under constant pressure , to obtain a W / O type emulsion; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com