Methods of forming solder areas on electronic components and electronic components having solder areas

A technology of electronic components and solder, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components, which can solve the problems of high labor intensity, high cost, and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

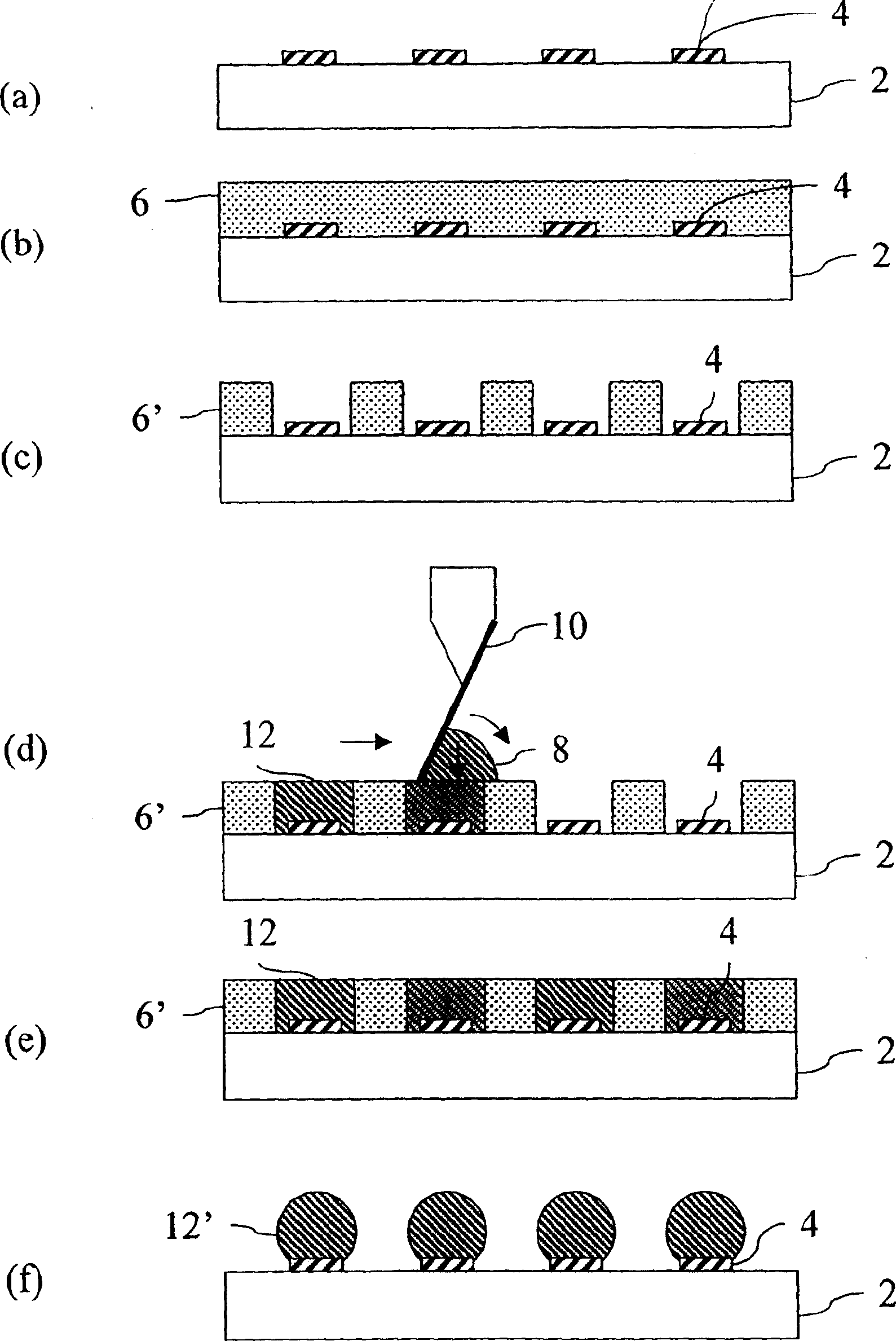

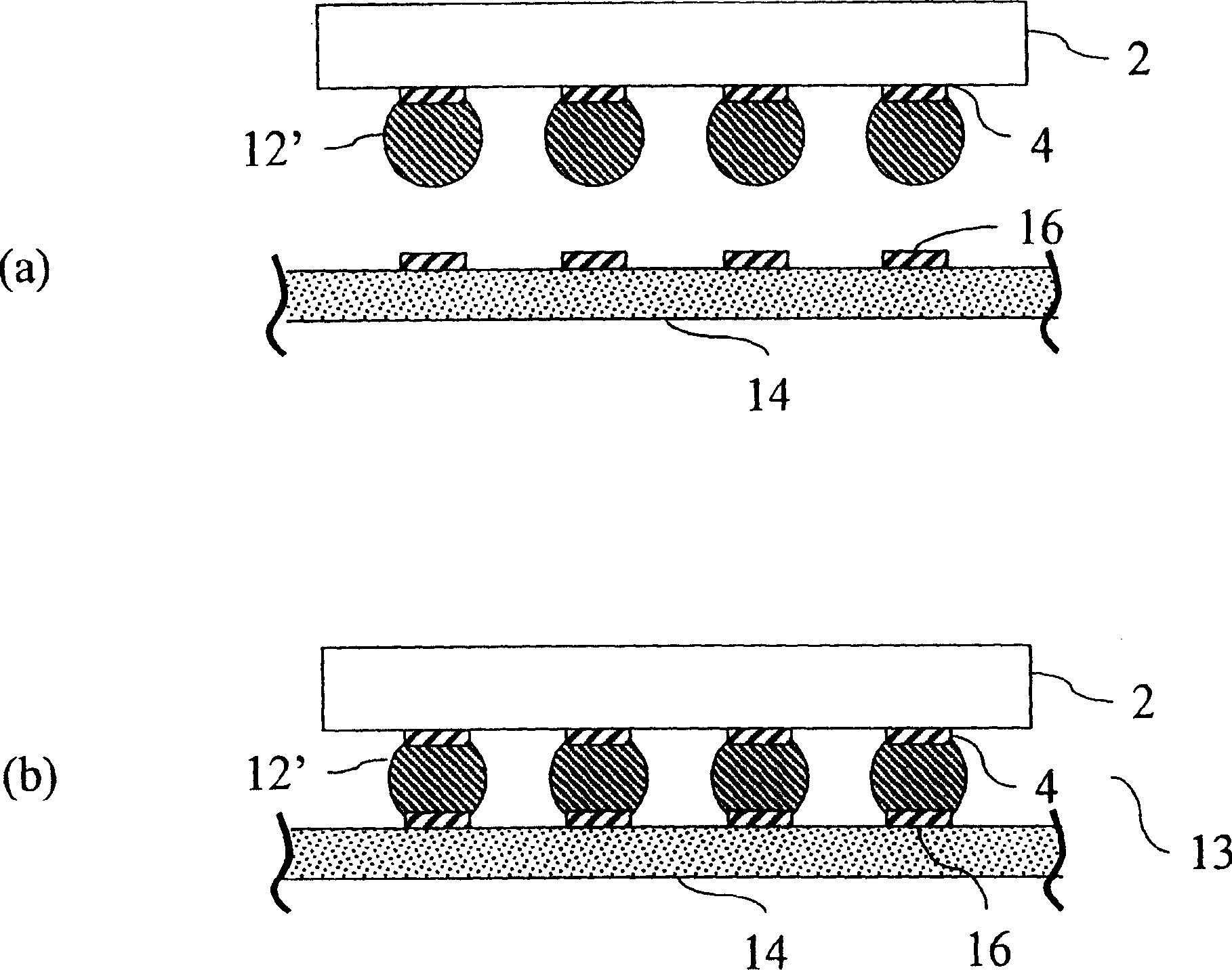

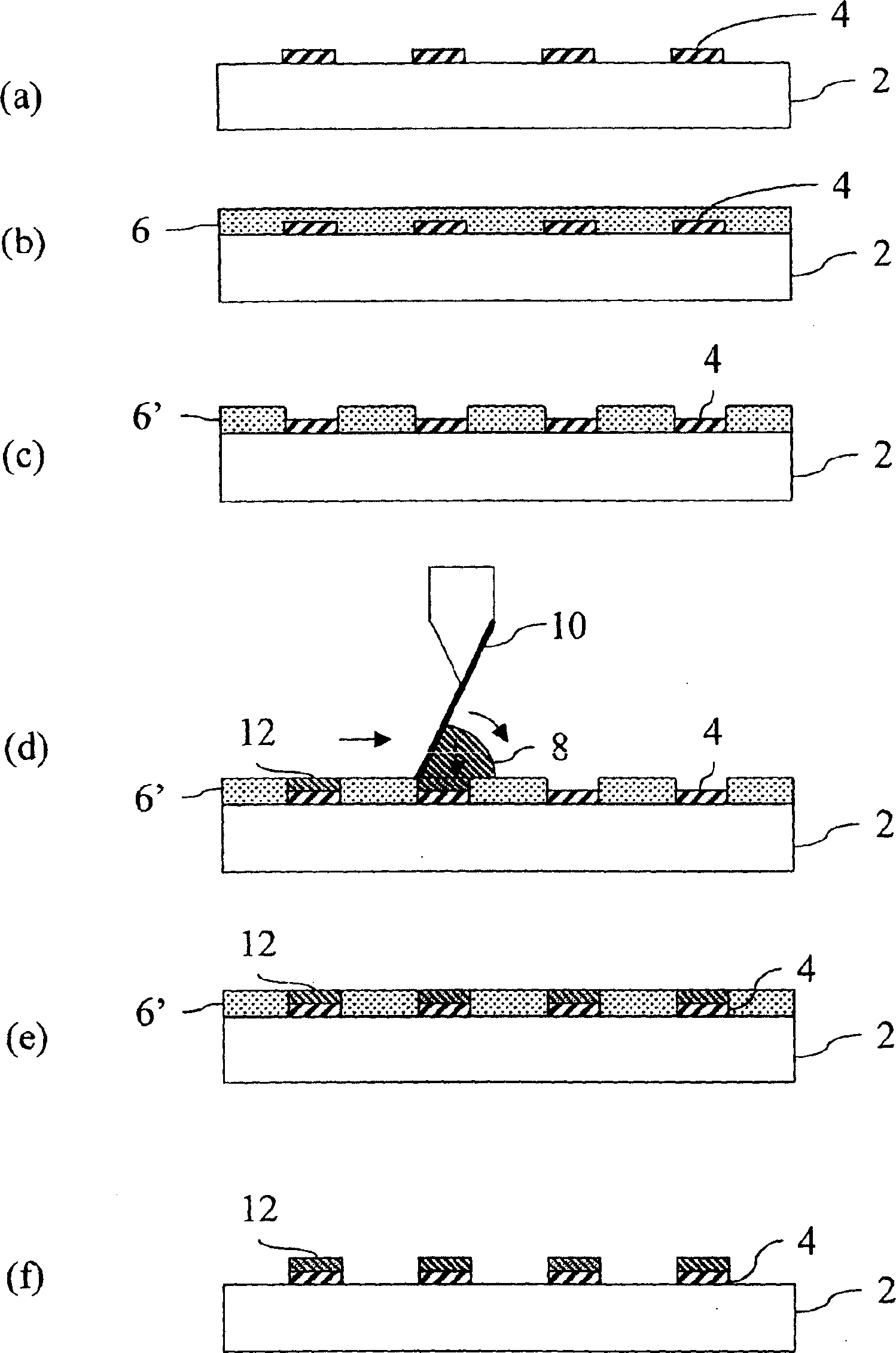

Method used

Image

Examples

Embodiment 1-10

[0046] Nanoparticle solder pastes according to the present invention were prepared as follows. A 0.25 M solution of benzoic acid was prepared from 0.92 g of benzoic acid and 20 ml of diethyl ether. 86 g of solder alloy nanoparticles were added to the solution and soaked for one hour with occasional stirring. The powder slurry is rinsed and dried. A rosin-based flux was prepared from 50 wt% rosin, 41 wt% ethylene glycol solvent, 4 wt% succinic acid, and 5 wt% castor oil. The flux was added to the metal particles to form a paste with 88 wt% metal, as shown in Table 1. The resulting solder paste was used to form solder lands on electronic devices as described below.

[0047] A semiconductor wafer having IC chips formed on its surface is provided. Each IC chip has 64 contact pads with a pitch of 100 μm (each side is 200 μm). A metal mask was placed in contact with the surface, the mask having openings with a diameter of 150 μm exposing the contact pads. Use the squeegee to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com