Post extraction production technology of pullulanose

A pullulan sugar and production process technology, applied in fermentation, ultrafiltration and other directions, can solve the problems of high steam consumption, flammable and explosive, unsafe, etc., and achieve high extraction yield, good quality, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

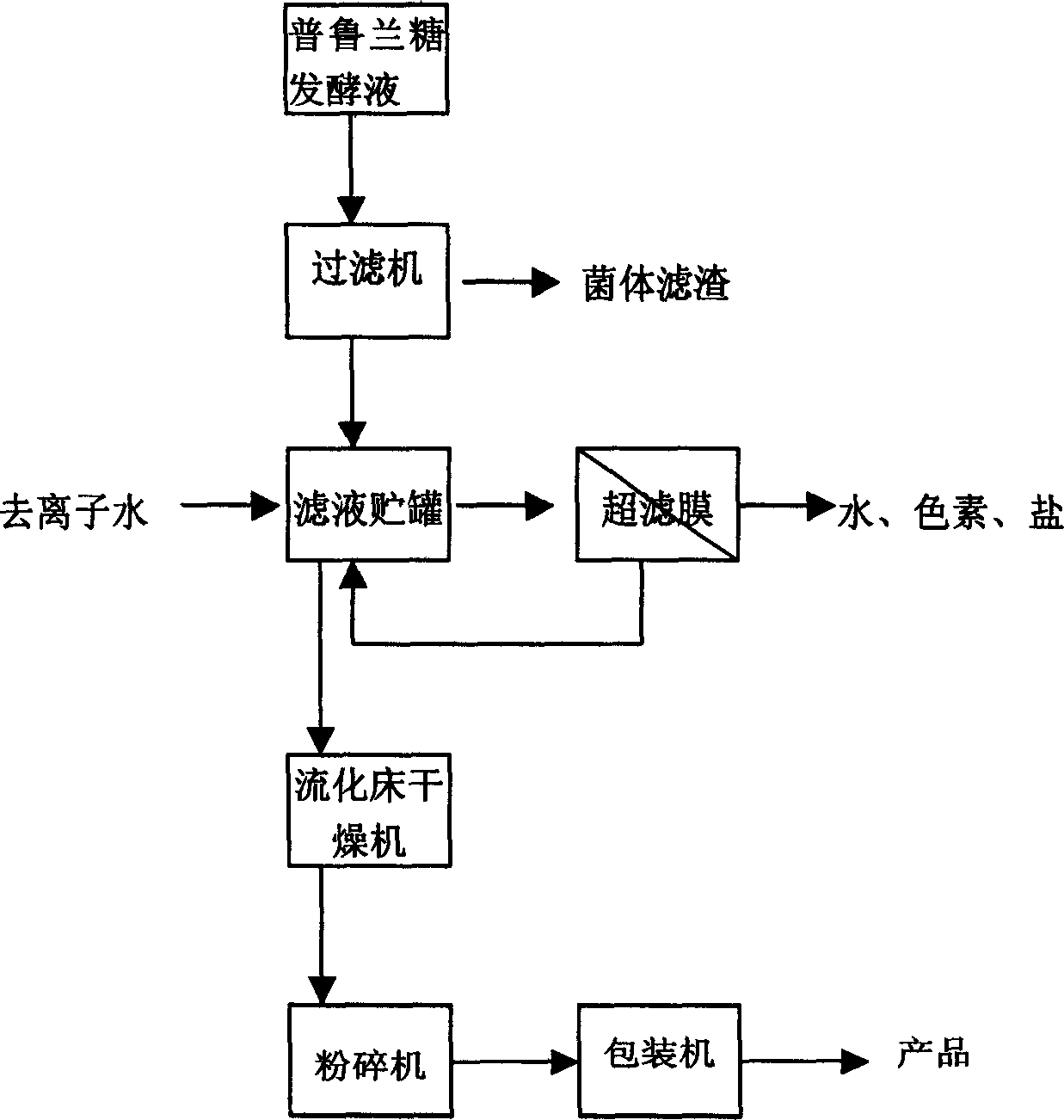

[0015] Post-extraction production process of pullulan: as shown in the figure.

[0016] 1. The pullulan fermentation liquid is filtered to remove bacteria, and the clear liquid is pumped into the filtrate storage tank.

[0017] 2, the clarification pullulan sugar fermented liquid (7m 3 ) into the hollow fiber ultrafiltration membrane separator, the molecular weight cut-off of the membrane is 6000D, the retained liquid is returned to the storage tank, and water, pigment and inorganic salt permeate the membrane. During this process, deionized water is continuously added to the storage tank to remove The additional amount of deionized water is 50% of the volume of the permeate. When the chroma and salinity reach the standard, stop adding deionized water; continue the ultrafiltration operation until the concentration reaches 20%.

[0018] 3. The concentrated pullulan solution is pumped into the fluidized bed, and dried to obtain a 430Kg sample. The extraction yield is 97.8%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com