Differential pressure control adaptive throttle expansion valve

A throttling expansion and self-adaptive technology, applied in the field of throttling expansion valve in the field of throttling refrigeration technology, can solve the problems of unstable system operation, larger valve opening, and smaller throttle valve opening under heavy load, etc. To achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

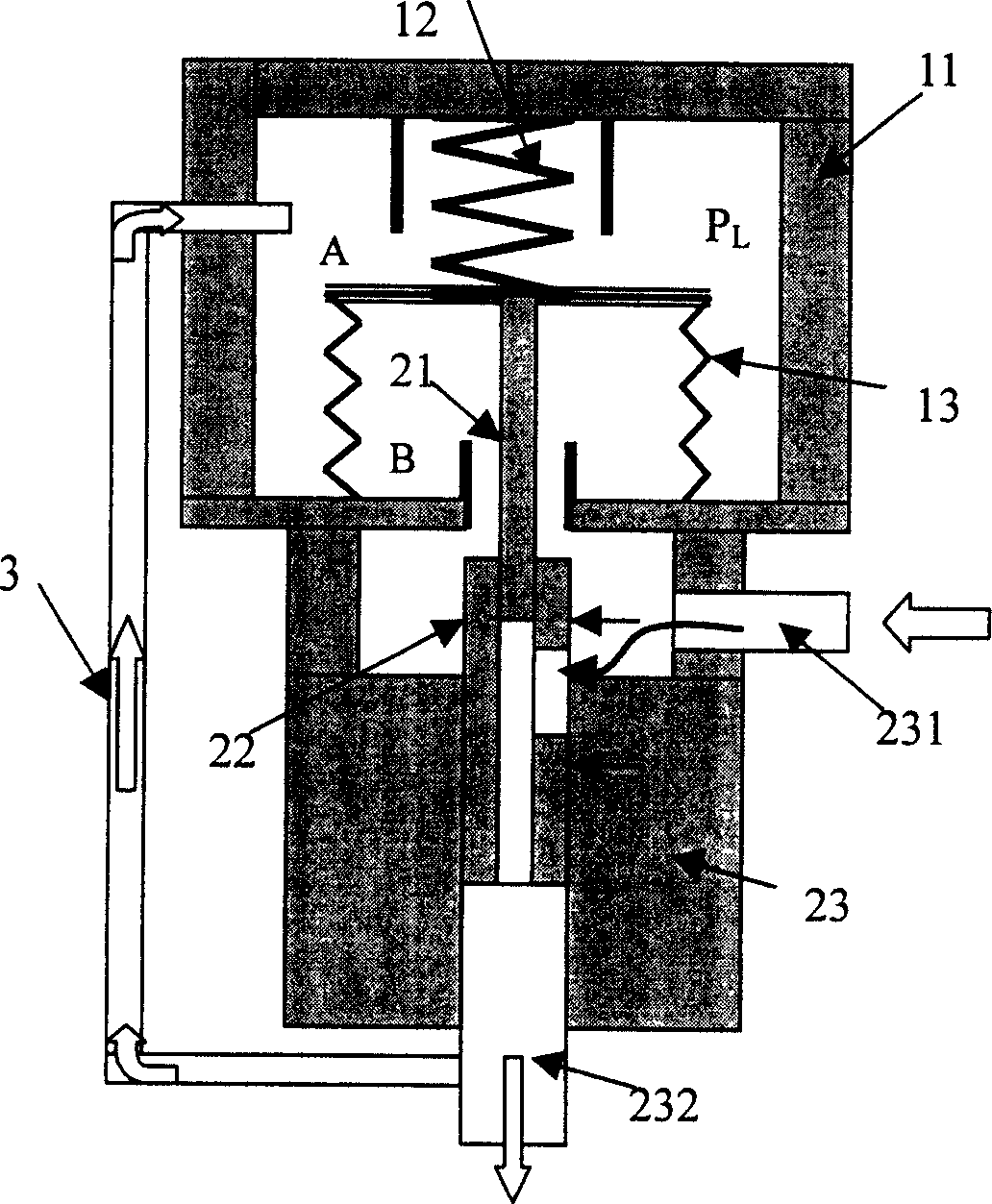

[0021] Example 1 Prepare an adaptive throttling expansion valve with differential pressure control, the structural diagram is shown in figure 1 .

[0022] The differential pressure controlled adaptive throttling expansion valve consists of:

[0023] A differential pressure sensing mechanism includes: a housing 11, an elastic element 12, and an elastic bellows 13 with one end closed; The outer side of the closed end of the tube 13 is fixedly connected to the inner top end of the shell 11, and the bottom end of the elastic bellows 13 is fixedly connected to the inner bottom end of the shell 11; a cavity A is formed between the elastic bellows 13 and the shell 11;

[0024] A flux regulating mechanism: including a transmission rod 21 connected to the inner top of the closed end of the elastic bellows 13, a valve needle 22 and a valve body 23; the valve body 23 has a through hole, and the valve needle 22 moves in the through hole of the valve body 23 Inside, its upper end is clos...

Embodiment 2

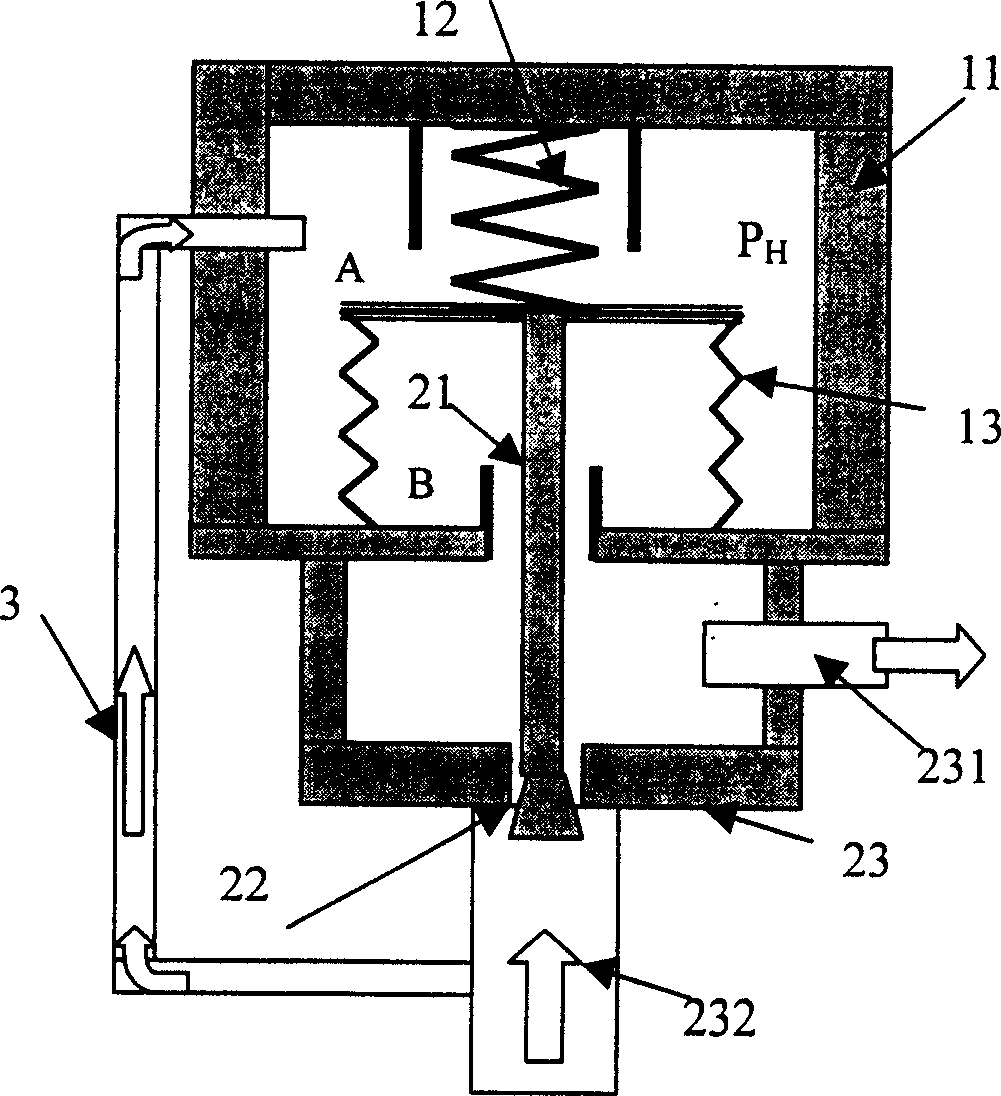

[0028] Example 2 Prepare an adaptive throttling expansion valve with differential pressure control, the structure diagram is shown in figure 2 .

[0029] The differential pressure controlled adaptive throttling expansion valve consists of:

[0030] A pressure difference sensing mechanism: including a casing 11, a tension spring 12, and an elastic bellows 13 with one end closed; the flux adjustment mechanism includes a transmission rod 21, a valve needle 22 and a valve body 23; its structure is: an elastic bellows with one end closed A chamber A is formed between 13 and the shell 11, a chamber B is formed between the bellows 13 and the valve body 23, and the tension spring 12 is used to balance the force generated by the pressure difference between the chambers A and B; the transmission rod 21 and the bellows The closed end of 13 is connected, and the valve needle 22 is connected to the top of the transmission rod 21; the change of pressure difference causes the bellows 13 to...

Embodiment 3

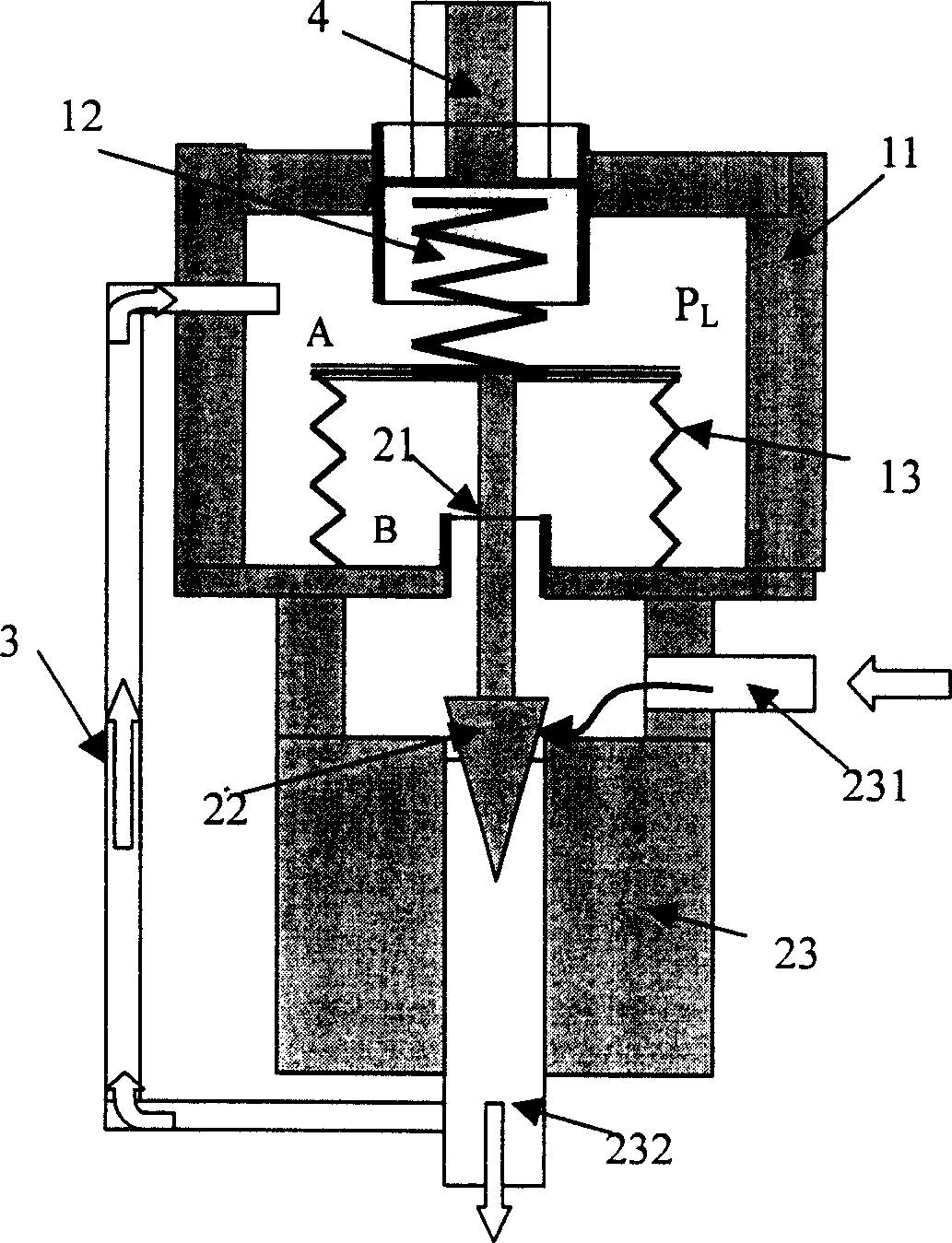

[0031] Example 3 Prepare an adaptive throttling expansion valve with differential pressure control, the structure diagram is shown in image 3 .

[0032] The self-adaptive throttling expansion valve with differential pressure control in this embodiment includes a differential pressure sensing mechanism and a flux regulating structure;

[0033] The differential pressure sensing mechanism includes a casing 11, a pressure spring 12, and an elastic bellows 13 with one end closed; the flux adjustment mechanism 2 includes a transmission rod 21, a valve needle 22 and a valve body 23; its structure is: an elastic bellows 13 with one end closed It forms a chamber A with the shell 11, the bellows 13 and the valve body 23 form a chamber B, and the pressure spring 12 is used to balance the force generated by the pressure difference between the chambers A and B; the transmission rod 21 is connected to the closed end of the bellows 13 , the valve needle 22 is connected to the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com