Curcumin and phosphatide composite and its preparation method

A curcumin phospholipid and a technology for describing curcumin phospholipid are applied in the field of medicine to achieve the effects of improving absorption and solving low bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 37g of curcumin (approximately equivalent to 0.1mol), dissolve it in 1000ml of absolute ethanol at 45°C to 55°C to obtain a red clear liquid, keep it warm at 55°C, add 75g of soybean lecithin (average molecular weight 750), and stir until The solution is clear, after about 10 minutes, connect the reflux device, shake and react for 1 hour while heating and keeping warm, remove the reflux device, concentrate under reduced pressure at 60°C until the reaction volume is 250ml, pour it into 2000ml of n-hexane immediately, the upper layer of the solution is yellow and turbid Liquid, the lower layer is a red oily substance, the red oily substance is taken, and vacuum-dried by a conventional method to obtain 102 g of a brick-red dried substance, which is the curcumin phospholipid complex.

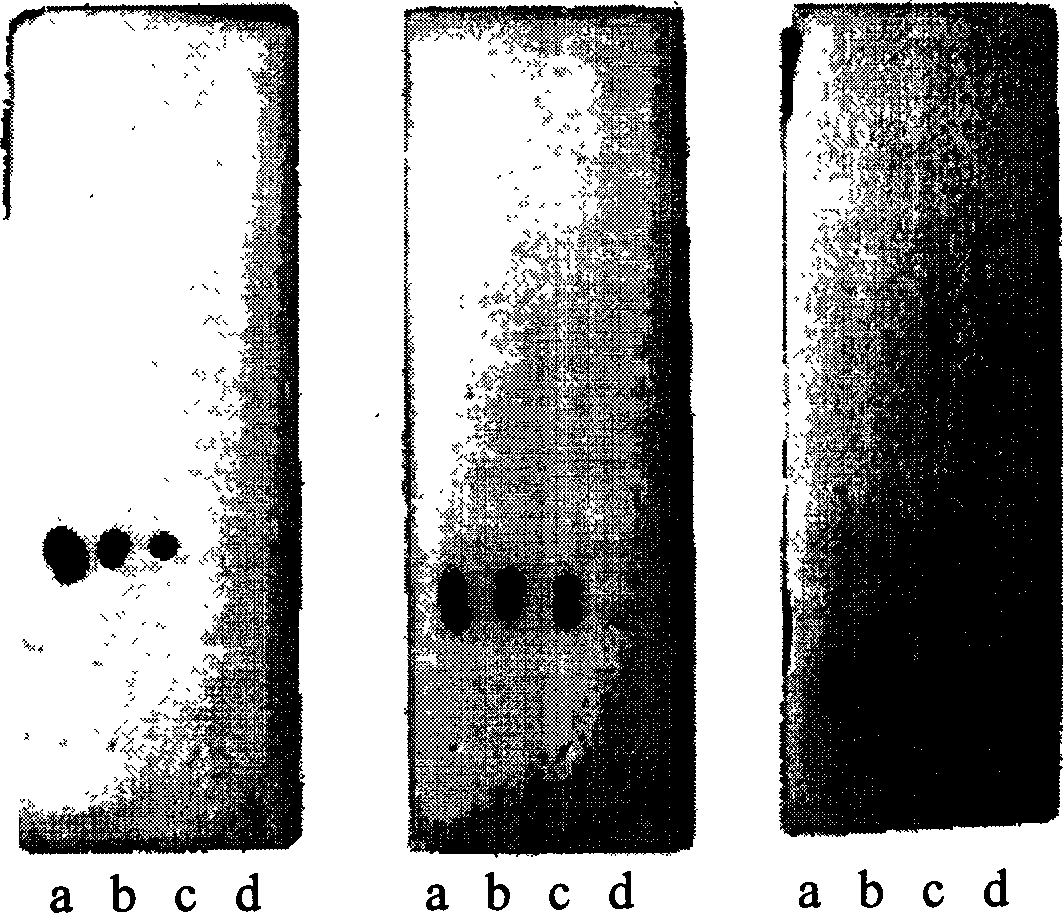

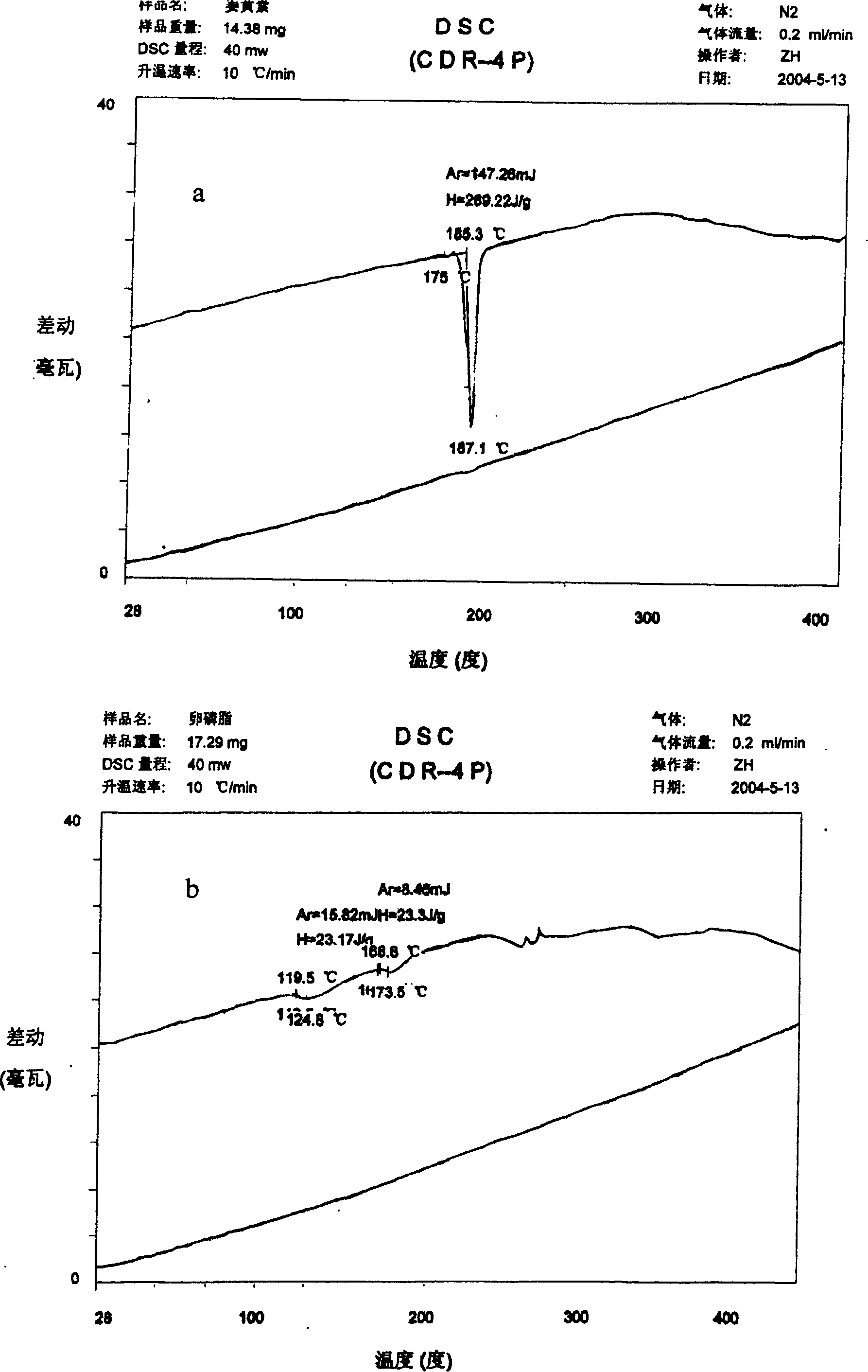

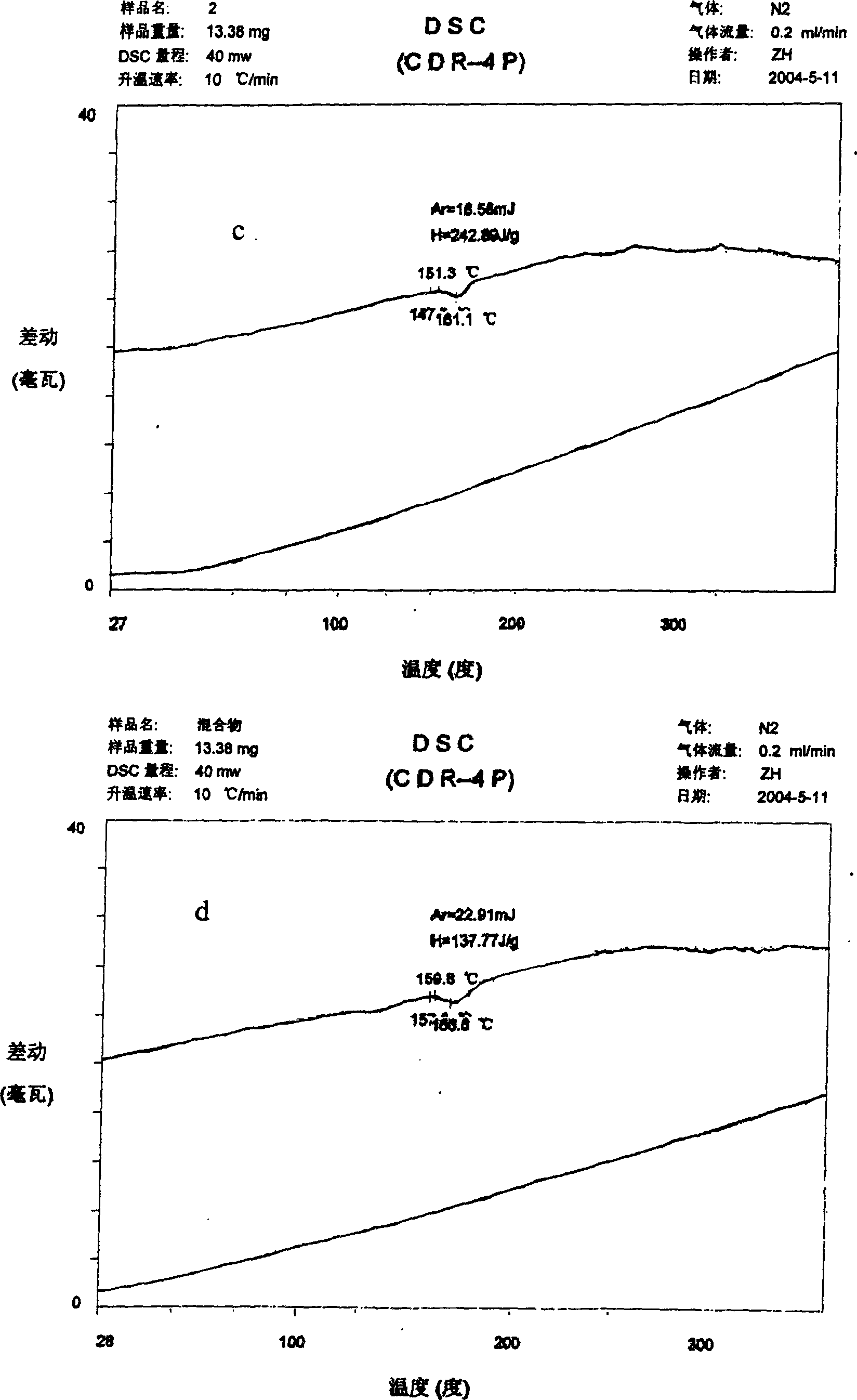

[0031] The following expansion systems were used respectively: ① ethyl acetate: methanol = 20: 1; ② ethyl acetate: acetone = 2: 1; ③ ethyl acetate: cyclohexane = 1: 2, curcumin, curcumin ...

Embodiment 2

[0038] Take 37g of demethoxycurcumin (Cur-2) (equivalent to approximately 0.1mol), dissolve it in 1000ml of acetone at 60°C to obtain a red clear liquid, keep it warm at 70°C, add approximately equivalent to curcumin or its derivatives Egg yolk lecithin (average molecular weight 780) of 2 times the molar amount is stirred until the solution is clear. After about 5 minutes, the reflux device is connected, and the reaction is shaken while heating and insulated for 2 hours. The reflux device is removed and concentrated in a vacuum until the reaction volume is 300ml. Immediately poured into 2500ml of n-hexane, the upper layer of the solution was a yellow turbid liquid, and the lower layer was a red oily substance. The red oily substance was taken and vacuum-dried to obtain 160g of a brick-red dried substance, which was the curcumin phospholipid complex.

Embodiment 3

[0040] Take dideoxycurcumin (Cur-3) 37g (equivalent to approximately 0.1mol), dissolve it in 1000ml of methanol at 40°C to obtain a red clear liquid, keep it warm at 40°C, and add approximately equivalent to curcumin or its derivatives 3 times the molar amount of lecithin (average molecular weight 700), stir until the solution is clear, about 15min, connect to the reflux device, shake and react for 1.5 hours while heating and keeping warm, remove the reflux device, and concentrate under reduced pressure at 60°C until the reaction volume is 200ml , immediately poured into 1500ml of n-hexane, the upper layer of the solution was a yellow turbid liquid, and the lower layer was a red oily substance, and the red oily substance was taken and vacuum-dried to obtain 230g of a brick-red dried substance, which was the curcumin phospholipid complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com