New film coating

A film and weight technology, applied in the direction of drug delivery, pharmaceutical formulations, etc., can solve the problems of film coating performance change, inappropriateness, stability impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

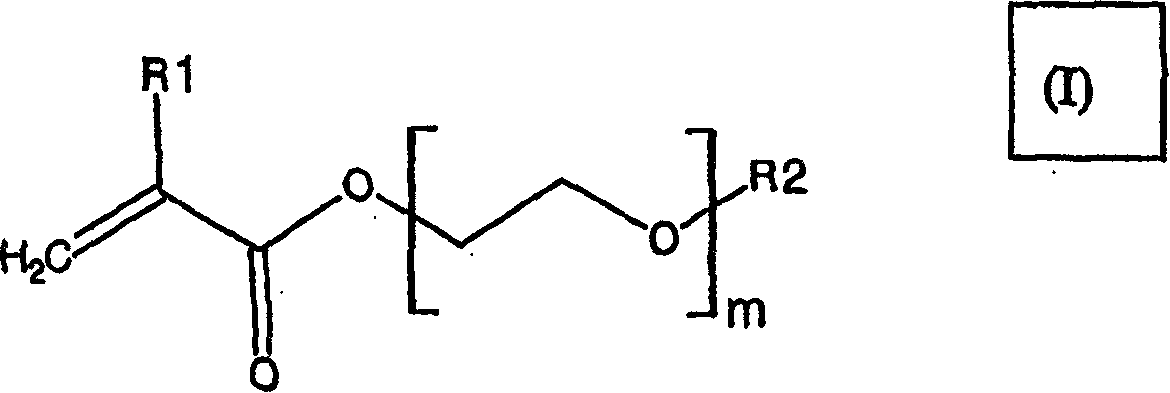

Method used

Image

Examples

Embodiment 1

[0174] Example 1: Synthesis of polymer dispersions using M1, M2 and M3

[0175] The polymerization was carried out using ethyl acrylate, 2-methyl methacrylate and monomers M1, M2 and M3.

[0176] Dispersions D1, D2 and D3 were prepared using the following components:

[0177] D1

[0178] Water 677.55g

[0179]Ethyl acrylate 217.75g

[0180] Methyl methacrylate 108.88g

[0181] Monomer M1 2.18g

[0182] Sodium dodecyl sulfate (SDS) 2.18g

[0183] NaHCO 3 (0.005M) 0.27g

[0184] Na 2 S 2 o 8 (Initiator) 1.67g

[0185] D2

[0186] Water 677.42g

[0187] Ethyl acrylate 218.23g

[0188] Methyl methacrylate 109.12g

[0189] Monomer M2 3.75g

[0190] SDS 2.19g

[0191] NaHCO 3 (0.005M) 0.27g

[0192] Na 2 S 2 o 8 1.72g

[0193] D3

[0194] Water 675.31g

[0195] Ethyl acrylate 218.85g

[0196] Methyl methacrylate 109.43g

[0197] Monomer M3 7.15g

[0198] SDS 2.19g

[0199] NaHCO 3 (0.005M) 0.27g

[0200] Na 2 S 2 o 8...

Embodiment 2

[0202] Example 2: Synthesis of polymer dispersion using M4

[0203] Dispersion D4 was prepared using the following components:

[0204] water 600g

[0205] Ethyl acrylate 120g

[0206] Methyl methacrylate 70g

[0207] Monomer M4 (hydroxyethyl methacrylate, see Table 1) 10g

[0208] SDS 3g

[0209] NaOH(1M) 2.3g

[0210] K 2 S 2 o 8 (Initiator) 0.6g

[0211] The monomer is distilled to remove the initiator. The emulsion polymerization was performed in a tightly capped water-jacketed vessel equipped with nitrogen sparging and stirring. Disperse monomer, SDS and sodium hydroxide in water and stir (50 rpm). The temperature was raised to 50°C and the initiator was added. After the polymerization was carried out for 20 hours, the temperature was set to 70°C and carried out for another 2 hours. The dispersion was then filtered and cooled.

Embodiment 3

[0212] Embodiment 3: prepare film F1-F4 by embodiment 1 and 2

[0213] About 10 ml each of the dispersions D1-D4 were poured into a Teflon mold to obtain monomer films F1-F4. The mold was then placed in a temperature and humidity chamber at 25° C. and 60% relative humidity for 19 hours for drying and film formation.

[0214] result:

[0215] The tackiness of the film was tested by simply handling the film manually. The films were subjected to permeability testing as described in Example 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com