Phosphorescent light-emitting component comprising organic layers

An organic layer and fluorescent technology, applied in the field of fluorescent emitting elements, can solve the problems of lowering OLED efficiency and failure to recombine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

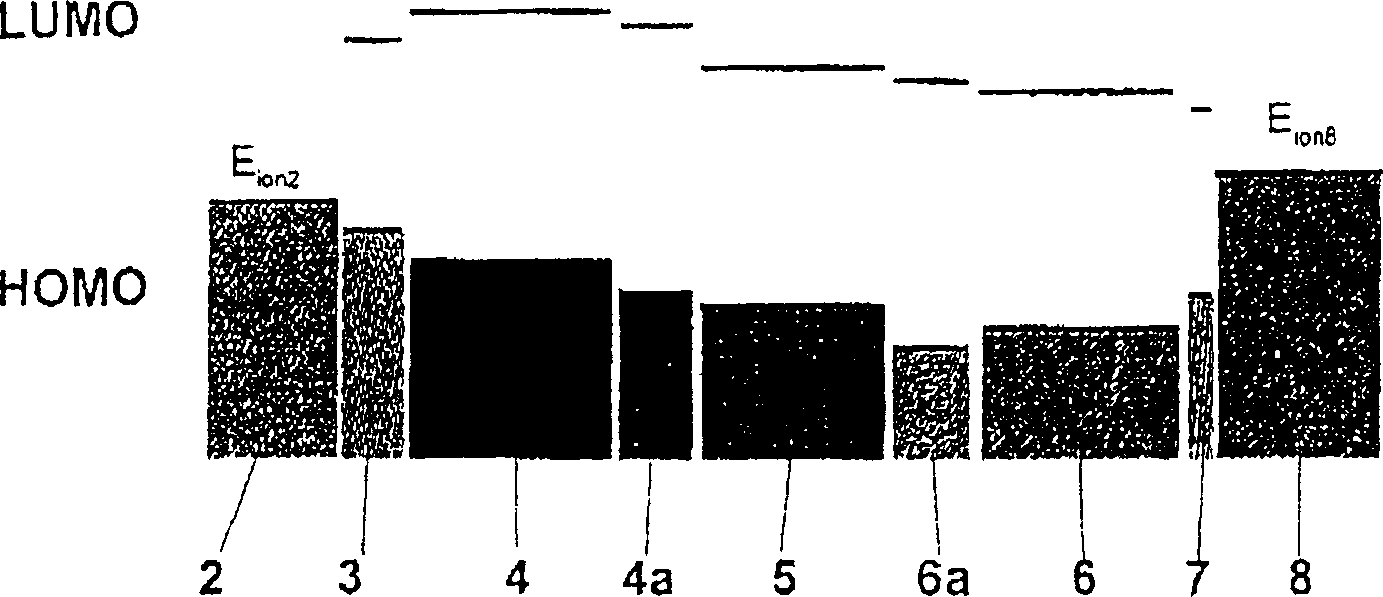

[0062] 1. Substrate,

[0063] 2. The bottom electrode, such as hole injection (anode),

[0064] 3. Hole injection layer,

[0065] 4. Hole Transport Layer (HTL),

[0066] 4a. If possible, there is a barrier layer on the hole side,

[0067] Light emitting area=multiple heterojunction (n=3)

[0068] 5A1d, hole transport material doped with emitter dopant (or bipolar transport material),

[0069] 5B1d or 5B1u, electron transport layer (or bipolar transport layer), may be doped with emitter dopants,

[0070] 5A2d, hole transport material doped with emitter dopant (or bipolar transport material),

[0071] 5B2d or 5B2u, electron transport layer (or bipolar transport layer), may be doped with emitter dopants,

[0072] 5A3d, hole transport material doped with emitter dopant (or bipolar transport material),

[0073] 5B3d or 5B3u, electron transport layer (or bipolar transport layer), may be doped with emitter dopants,

[0074] 6. Electron Transport Layer (ETL),

[0075] 7. Electron injectio...

example 2

[0081] 1. Glass substrate,

[0082] 2. ITO anode,

[0083] 4. Star-shaped (MTDATA) doped with F4-TCNQ 100nm (increased conductivity),

[0084] 4a. TPD (Triphenyldiamine), 5nm, HOMO=-5.4eV, LUMO=-2.4eV, light emitting area=multiple heterojunction (n=3)

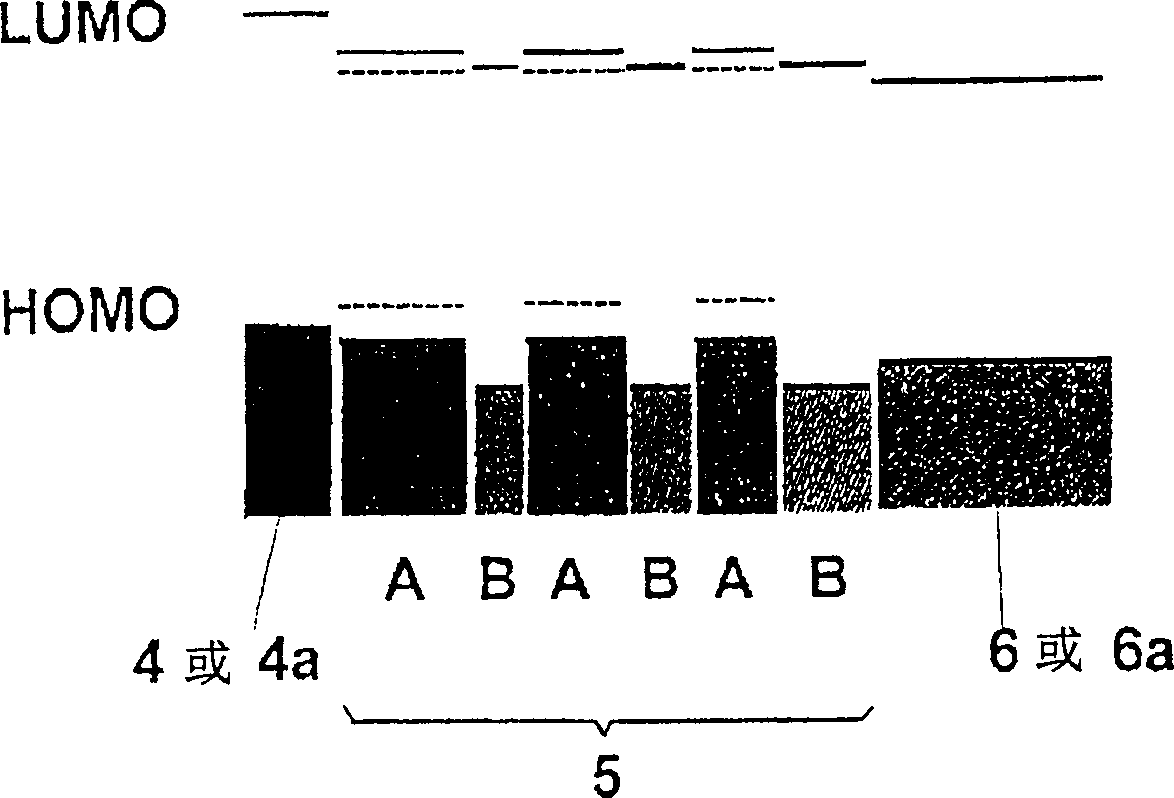

[0085] 5A1d, Ir(ppy)3 doped TCTA used as a three-state emitter, 10nm,

[0086] 5B1u, BPhen 5nm

[0087] 5A2d, TCTA: Ir(ppy)3 15nm

[0088] 5B2u, BPhen 5nm

[0089] 5A3d, TCTA: Ir(ppy)3 2nm

[0090] 5B3u, BPhen 10nm

[0091] 6. Alq3 40nm

[0092] 7. LiF (lithium fluoride) 1nm,

[0093] 8. Aluminum (cathode).

[0094] In this case, the interface AB is embodied, so that holes are blocked more effectively at the interface AB. This is necessary because only material A is doped with emitter dopants, and therefore there is a higher charge carrier density in material A. However, it is even more important that the three-state excitons in B have a greater energy than the energy in A. Therefore, the excitons generated on B can later be conver...

example 3

[0103] 1. Substrate,

[0104] 2. Bottom electrode, for example, ITO anode,

[0105] 3. Hole injection layer, such as phthalocyanine,

[0106] 4. Hole transport layer, such as MTDATA: F4-TCNQ,

[0107] 4a. The barrier layer on the hole side, such as TPD,

[0108] Light emitting area=multiple heterojunction (n=1)

[0109] 5AId, a hole transport layer doped with emitter dopants, such as TCTA: Ir(ppy)3,

[0110] 5B1d, electron transport layer and hole blocking layer doped with emitter dopants, such as Bphen:Ir(ppy)3,

[0111] 6a. The barrier layer on the electron side, such as BCP,

[0112] 6. Electron transport layer, such as Alq3,

[0113] 7. Electron injection layer, such as LiF,

[0114] 8. The top electrode (cathode), such as aluminum.

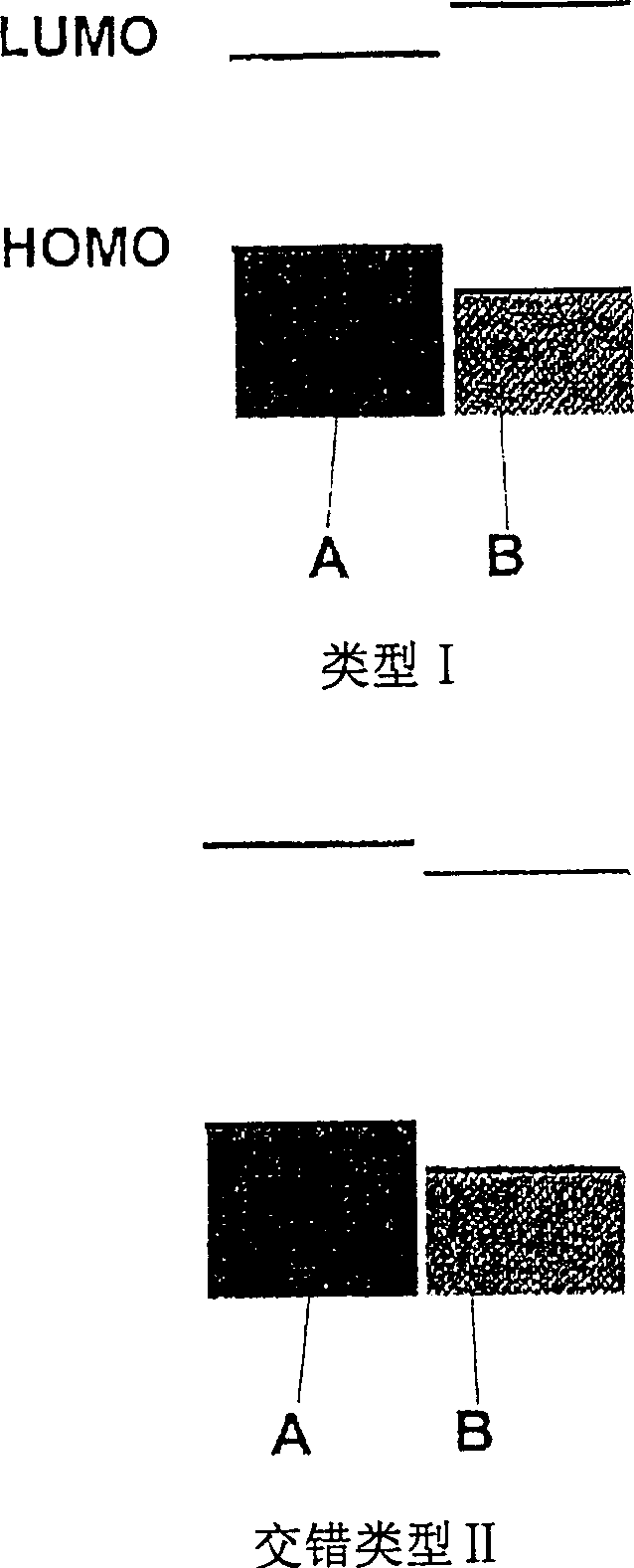

[0115] The formation of excitons in this OLED structure again occurs near the interfaces 5A1 and 5B1 (because the latter forms a "staggered II heterojunction"). The interface excitons can transfer their energy to the three-state excitons in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com