Polybenzazole fiber and use thereof

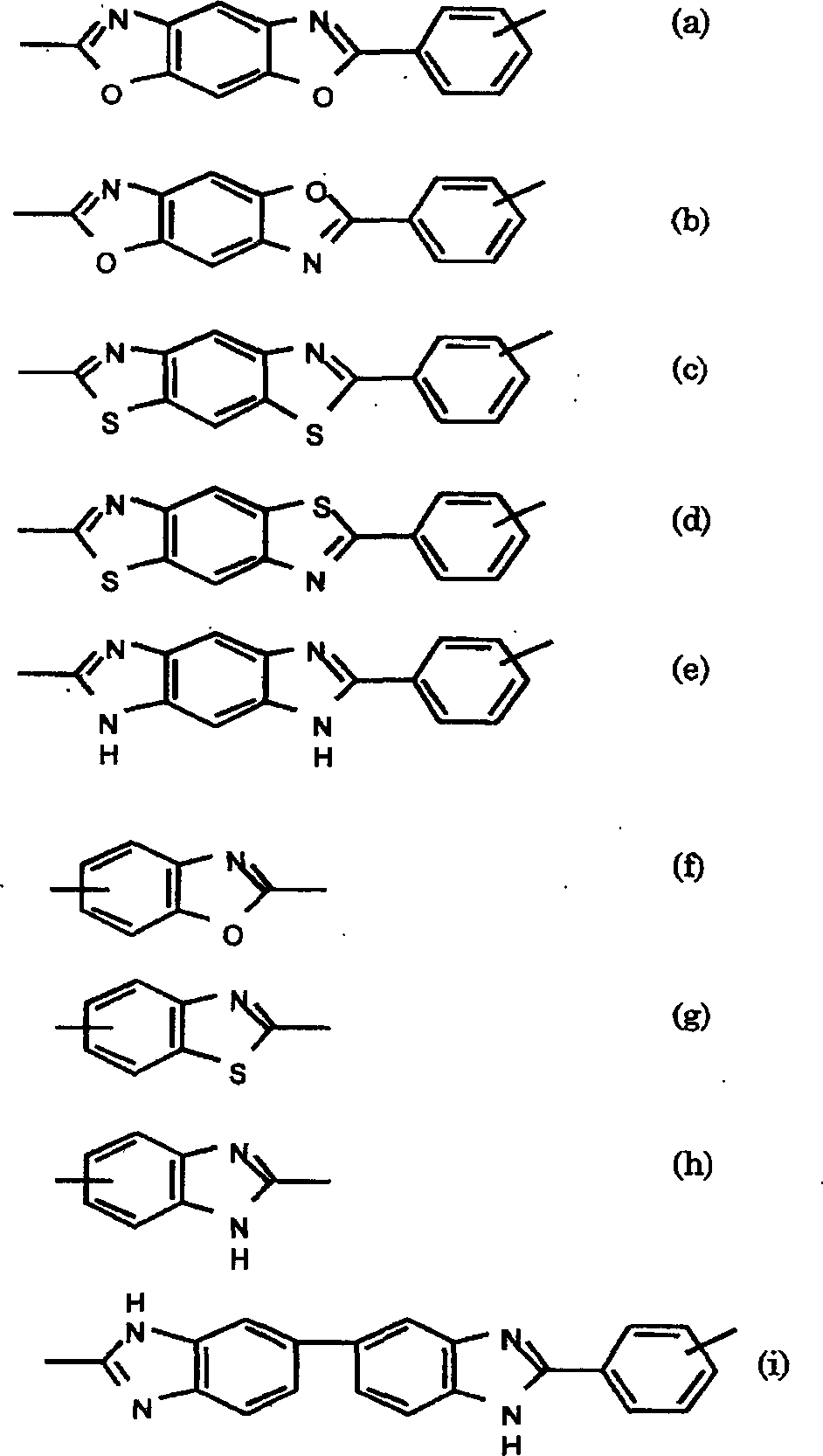

一种聚吲哚纤维、纤维的技术,应用在纤维化学特征、单组分合成聚合物人造丝、船只建造等方向,能够解决无法长期地穿戴、穿着感差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Under a nitrogen stream, 334.5 g of 4,6-diaminoresorcinol dihydrochloride, 260.8 g of terephthalic acid, and 2078.2 g of 122% polyphosphoric acid were stirred at 60° C. for 30 minutes, and then slowly heated to allow them to The reaction was carried out at 135°C for 20 hours, at 150°C for 5 hours, and at 170°C for 20 hours. Add 29H, 31H-phthalocyanine salt (2-)- N29, N30, N31, N32 copper 15.2g and stir to mix. Spinning is then carried out as described above. Table 1 shows the results of a high-temperature, high-humidity storage test (80°C, 80RH%) and a light exposure test performed on the obtained silk.

Embodiment 2

[0105] To 2.0 kg of the poly(p-phenylene benzobisoxazole) stock solution with an intrinsic viscosity of 29 dL / g obtained in the same manner as in Example 1, bis-benzimidazolo[2,1-b:2′,1 15.2 g of '-i]benzo[lmn][3,8]phenanthroline-8,17-dione were stirred and mixed. Spinning is then carried out as described above. Table 1 shows the results of a high-temperature, high-humidity storage test (80°C, 80RH%) and a light exposure test performed on the obtained silk.

Embodiment 3

[0107] Add 9,19-dichloro-5,15-diethyl-5 , 15.2 g of 15-dihydrodioindo[2,3-c: 2′,3′-n]tribenzodioxazine and stirred and mixed. Spinning is then carried out as described above. Table 1 shows the results of a high-temperature, high-humidity storage test (80°C, 80RH%) and a light exposure test performed on the obtained silk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength retention rate | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com