Pelletized feed for java tilapia clean fish and manufacturing method thereof

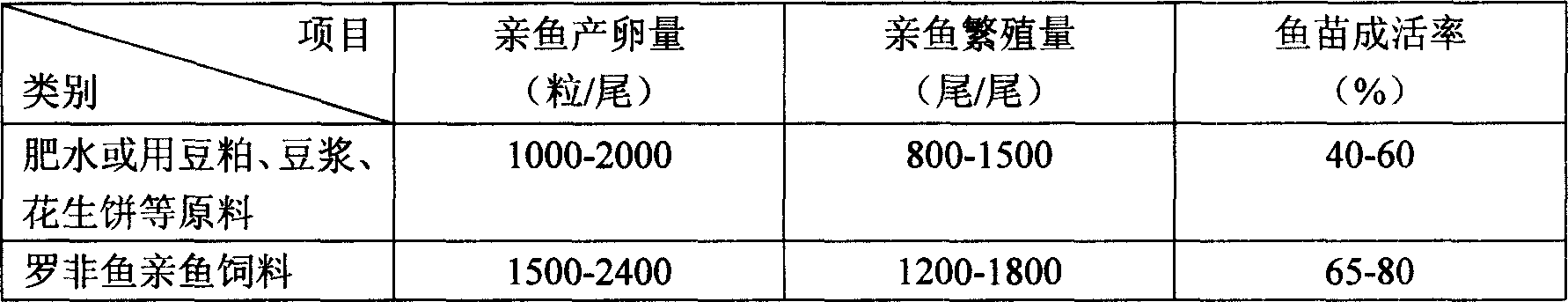

A technology of pellet feed and tilapia, applied in animal feed, animal feed, food preparation and other directions, can solve the problems of low spawning amount of broodstock, poor anti-stress ability of fry, restricting the healthy development of tilapia aquaculture, etc. To achieve the effect of healthy internal organs of broodstock, increase the survival rate of fry, and ensure healthy reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation steps:

[0045] ①Firstly crush 95% of fish meal, soybean meal, corn gluten powder, yeast powder, malt root, corn, soybean lecithin powder and pass through 40 mesh

[0046] ②Weigh the raw materials respectively according to the above formula, and mix them thoroughly with a mixer (CV≤5%)

[0047] ③Put the above-mentioned mixed materials through a steam granulation system at 80-85°C to granulate, the particle size is 2.5-3.5mm, dry in a cooler, remove powder by grading sieve, and pack after passing the inspection.

Embodiment 2

[0050] Preparation steps:

[0051] ① Firstly crush 95% of fish meal, soybean meal, corn gluten powder, yeast powder, malt root, corn, bran, soybean lecithin powder and pass through 40 mesh

[0052] ②Weigh the raw materials respectively according to the above formula, and mix them thoroughly with a mixer (CV≤5%)

[0053] ③Put the above-mentioned mixed materials through a steam granulation system at 80-85°C to granulate, the particle size is 2.5-3.5mm, dry in a cooler, remove powder by grading sieve, and pack after passing the inspection.

Embodiment 3

[0055] fish meal

[0056] Preparation steps: with embodiment 2

[0057] Example 3

[0058] fish meal

[0059] Preparation steps: with embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com