Purification catalyst for exhaust gas, production method therefor, and purification catalyst device for exhaust gas

A technology for exhaust gas purification and manufacturing method, which is applied in exhaust devices, catalyst activation/preparation, chemical elements of heterogeneous catalysts, etc., and can solve problems such as reduction of active points and reduction of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

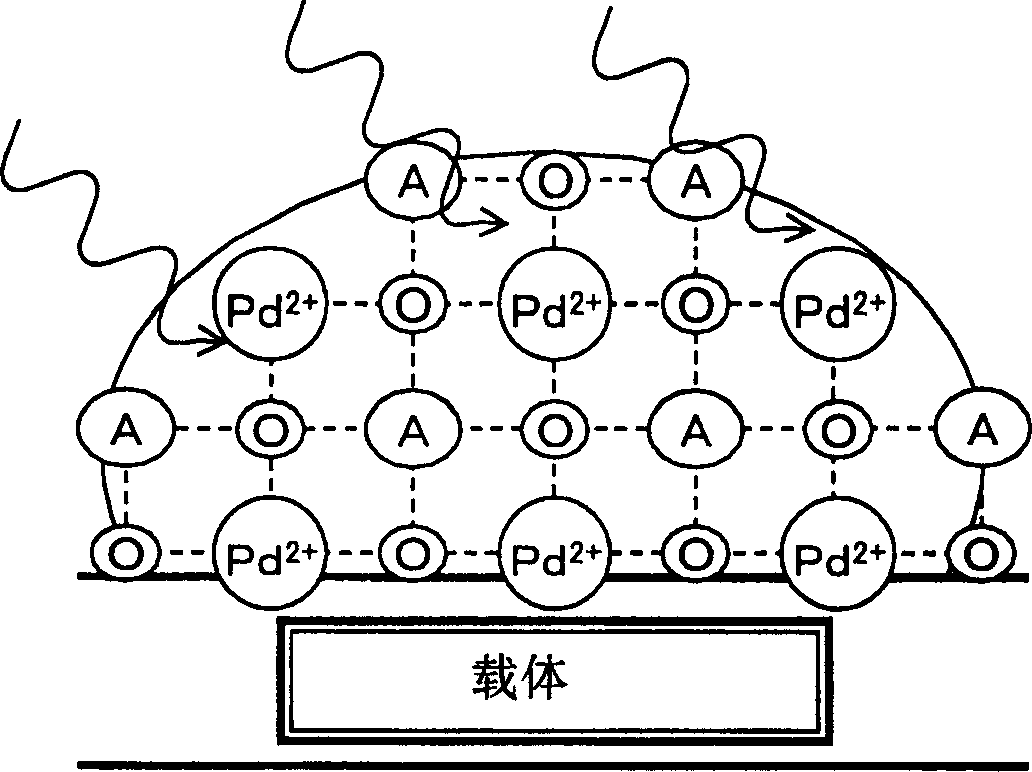

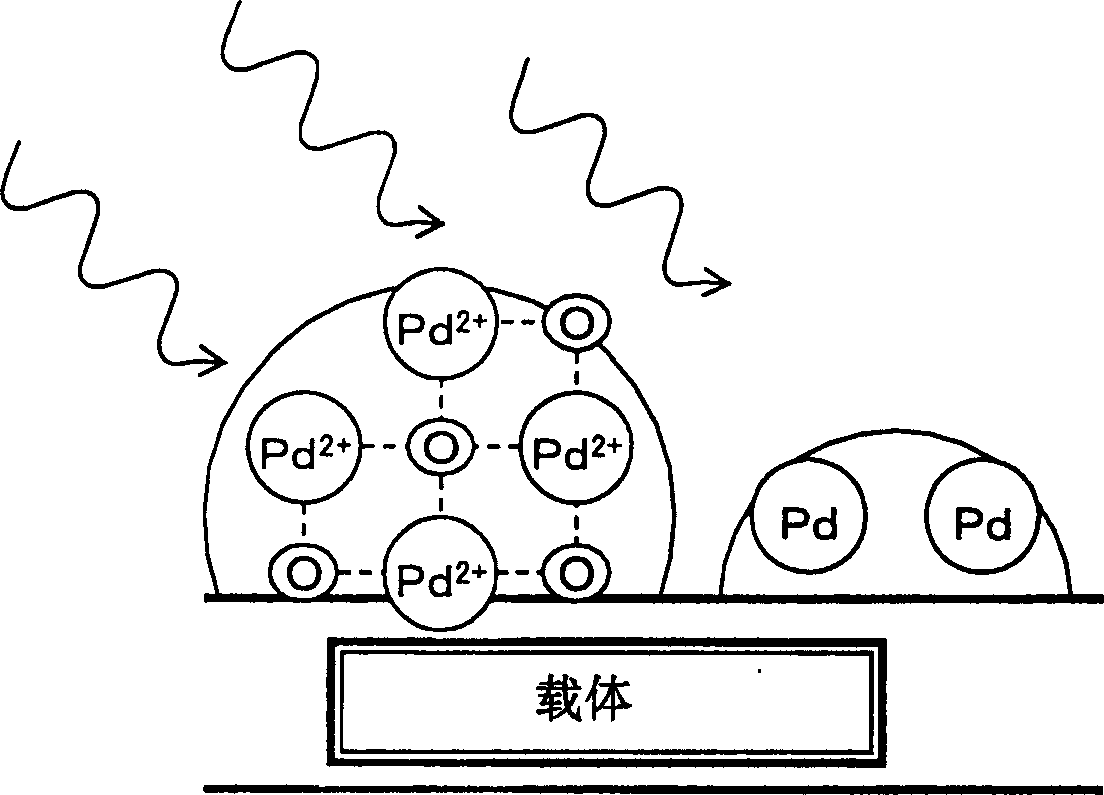

Method used

Image

Examples

Embodiment

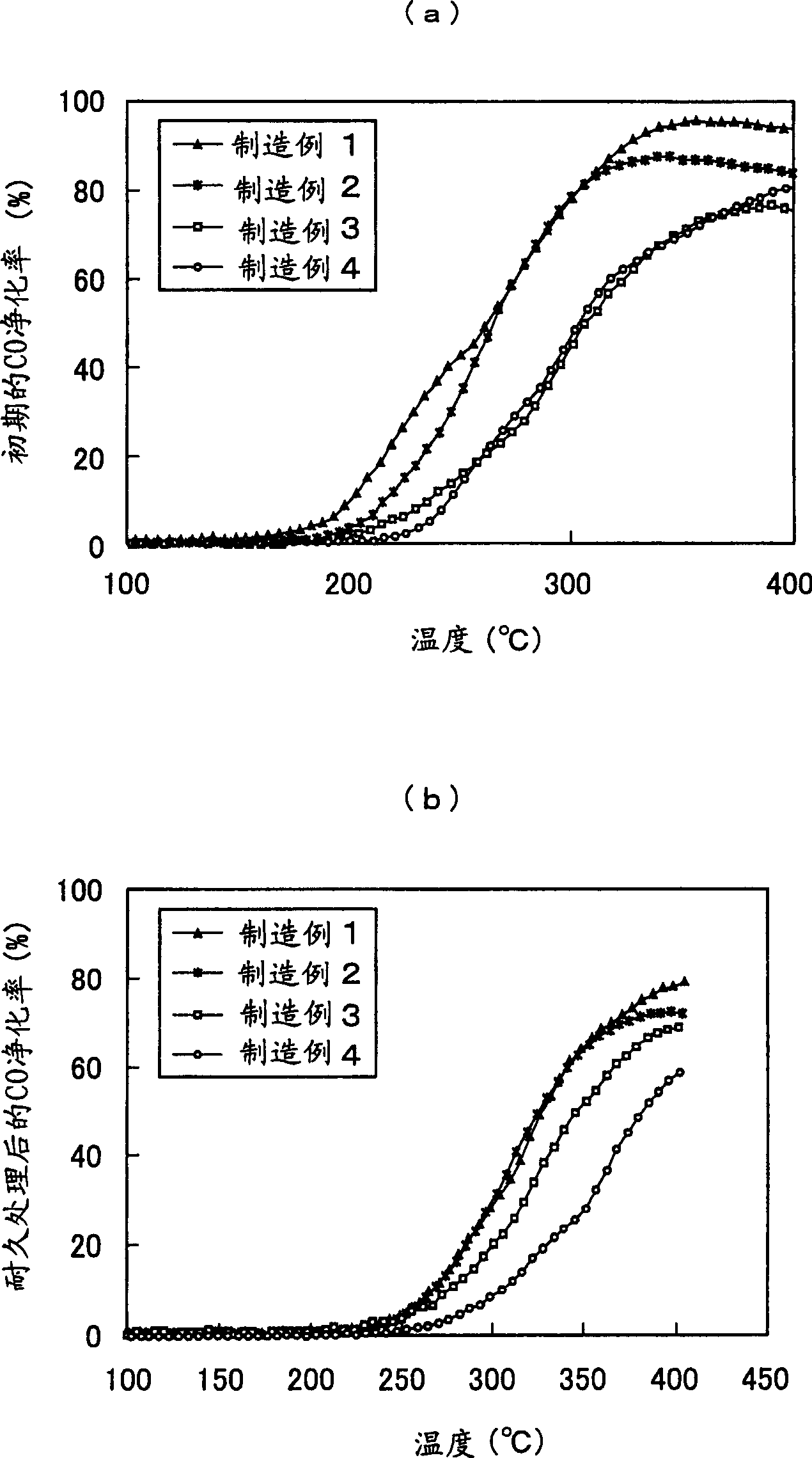

[0057] The present invention will be described in further detail below according to the examples.

[0058] 1. First Embodiment

manufacture example 1

[0060] 2.96 g (0.014 mol) of strontium nitrate, 1.86 g (0.007 mol) of palladium nitrate, and 3.75 g (0.028 mol) of malic acid were dissolved in 100 ml of ion-exchanged water to prepare a mixed metal nitrate aqueous solution. Then prepare the above-mentioned mixed metal nitrate aqueous solution, put it on the electric hot plate stirrer, stir it with a stirring bar, and evaporate and dry it at 250°C at the same time, then transfer it to an alumina crucible, and use a muffle furnace to heat the mixture at 2.5°C / min The speed is raised to 350°C, and heat treatment is performed at 350°C for 3 hours. Thus, a pseudo-calcined body from which nitrate groups were removed was produced.

[0061] The above-mentioned to-be-roasted body was pulverized and mixed for 15 minutes in a mortar, and then put into an alumina crucible, and the temperature was raised to 750°C with a muffle furnace at a rate of 5°C / min, and kept at 750°C for 10 hours to perform the main roasting. Next, the catalyst po...

manufacture example 2

[0063] Using barium nitrate instead of the strontium nitrate used in the above Production Example 1, Ba 2 PdO 3 exhaust gas purification catalyst. The other conditions were the same as in Production Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com