Waste heat solar energy system

A technology of solar energy and electric energy, which is applied in the directions of solar thermal power generation, mechanical power generated by solar energy, machines/engines, etc., and can solve problems such as increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description describes the present invention in detail through examples, but does not limit the present invention. This specification will ensure that those of ordinary skill in the art make and use the invention, and describe several embodiments, uses, modifications, improvements, and use of the invention, including the best mode for carrying out the invention.

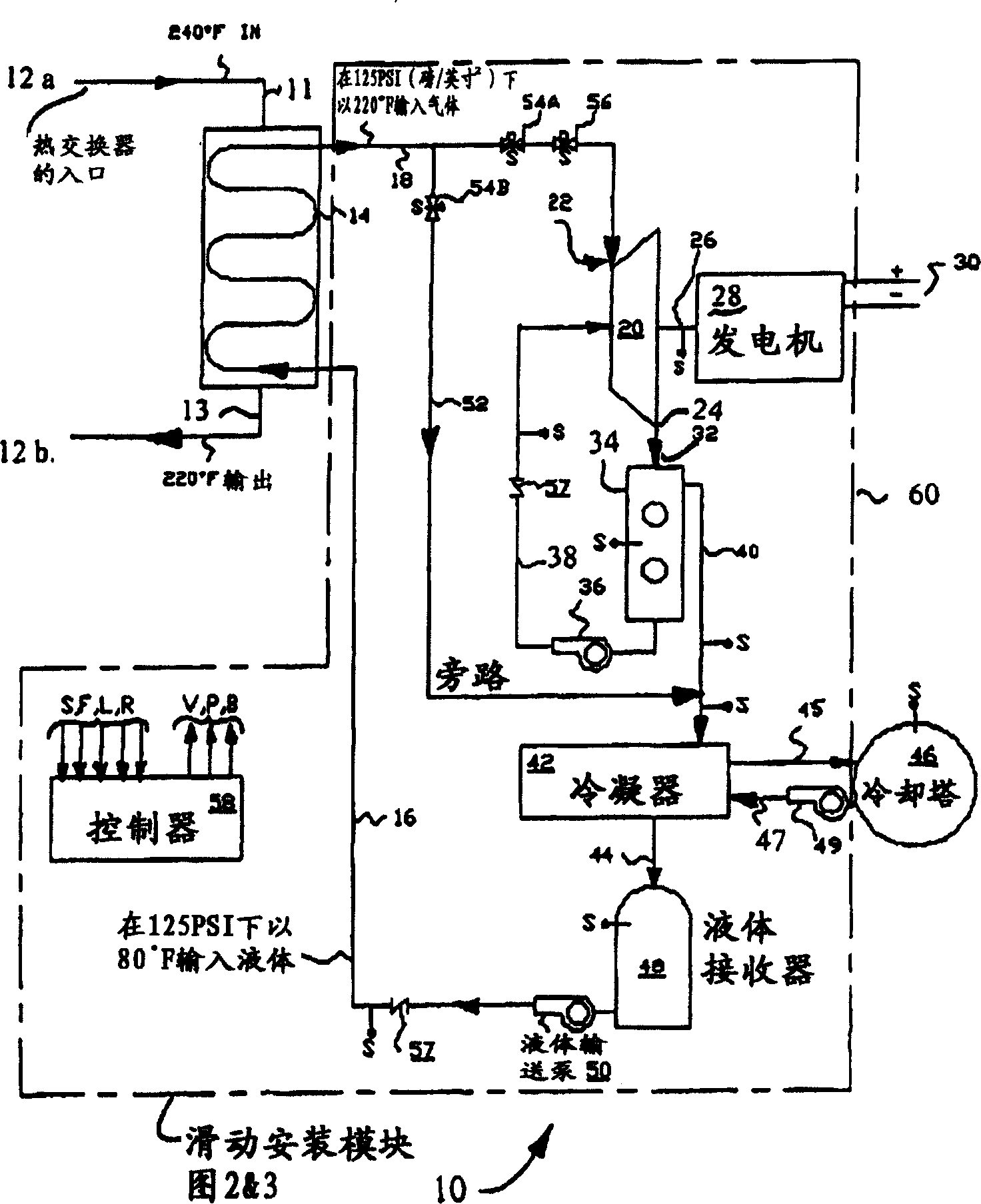

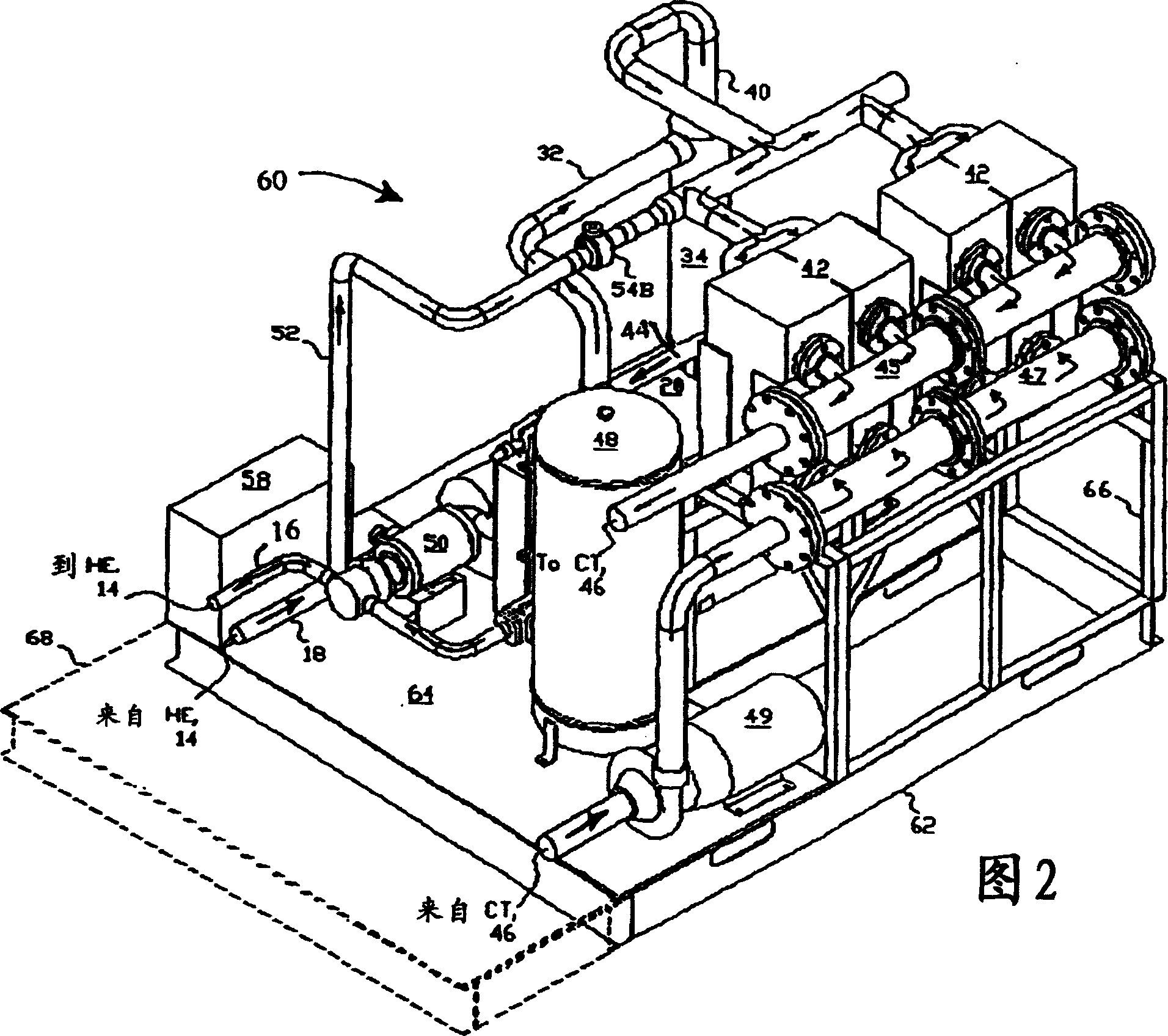

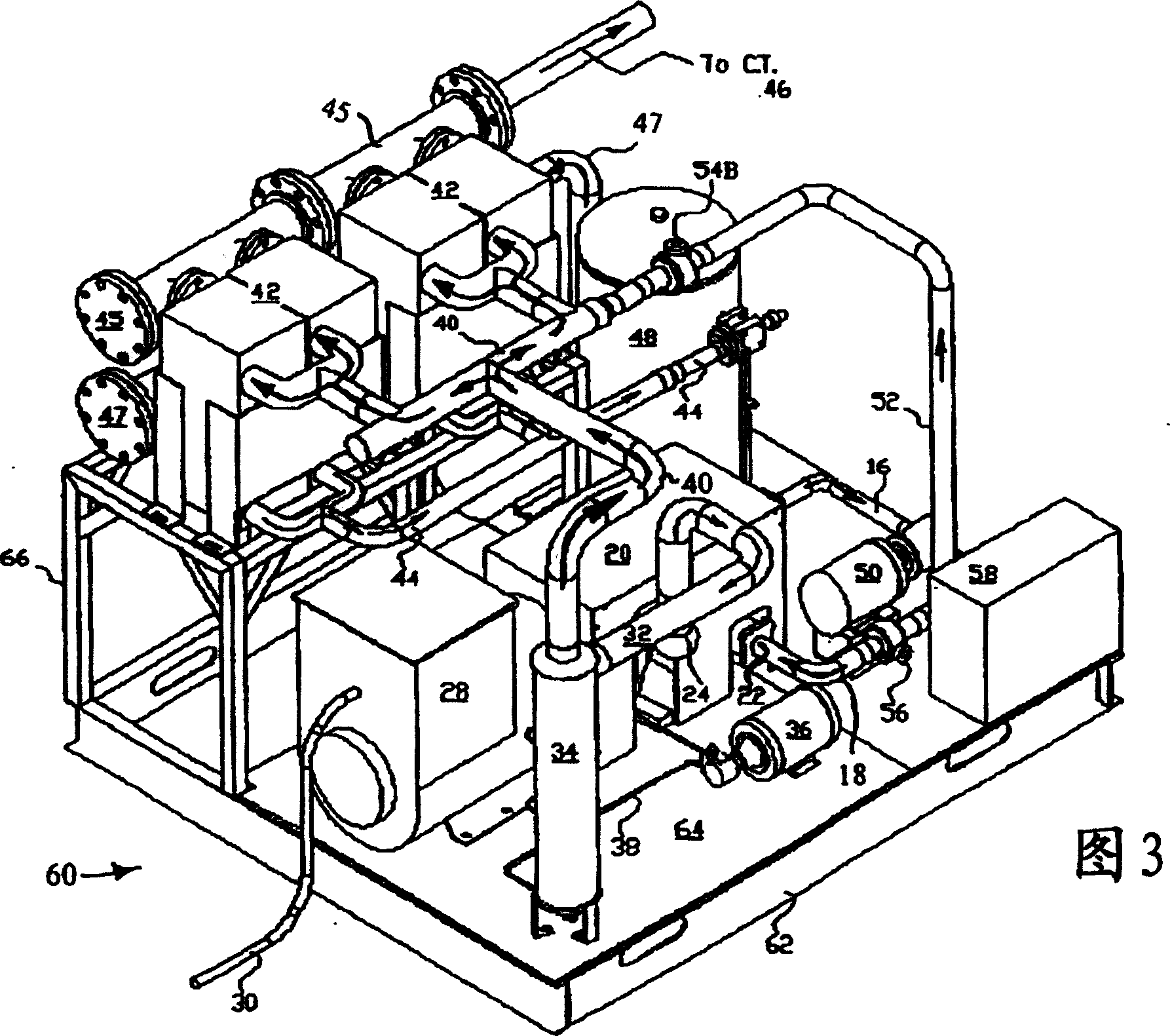

[0036] The present invention is shown in detail in several drawings. It is very complex, with many elements, interrelationships and combinations, and cannot be simply represented by a patent-type view. For clarity and conciseness, several drawings schematically show, or omit elements that are not essential in the figures, and only show elements that describe specific features, aspects, and principles of the present invention. Thus, a preferred embodiment of a certain feature can be displayed in one embodiment, and another feature can be displayed in another view. In terms of materials and test data, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com