Inner mold for molding glass and its regeneration process

A kind of molding and glass technology, which is applied in the field of mold core and regeneration of molded glass, can solve the problems of bad influence of production cost, thick intermediate layer, etc., achieve excellent reproducibility, short regeneration time, and increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

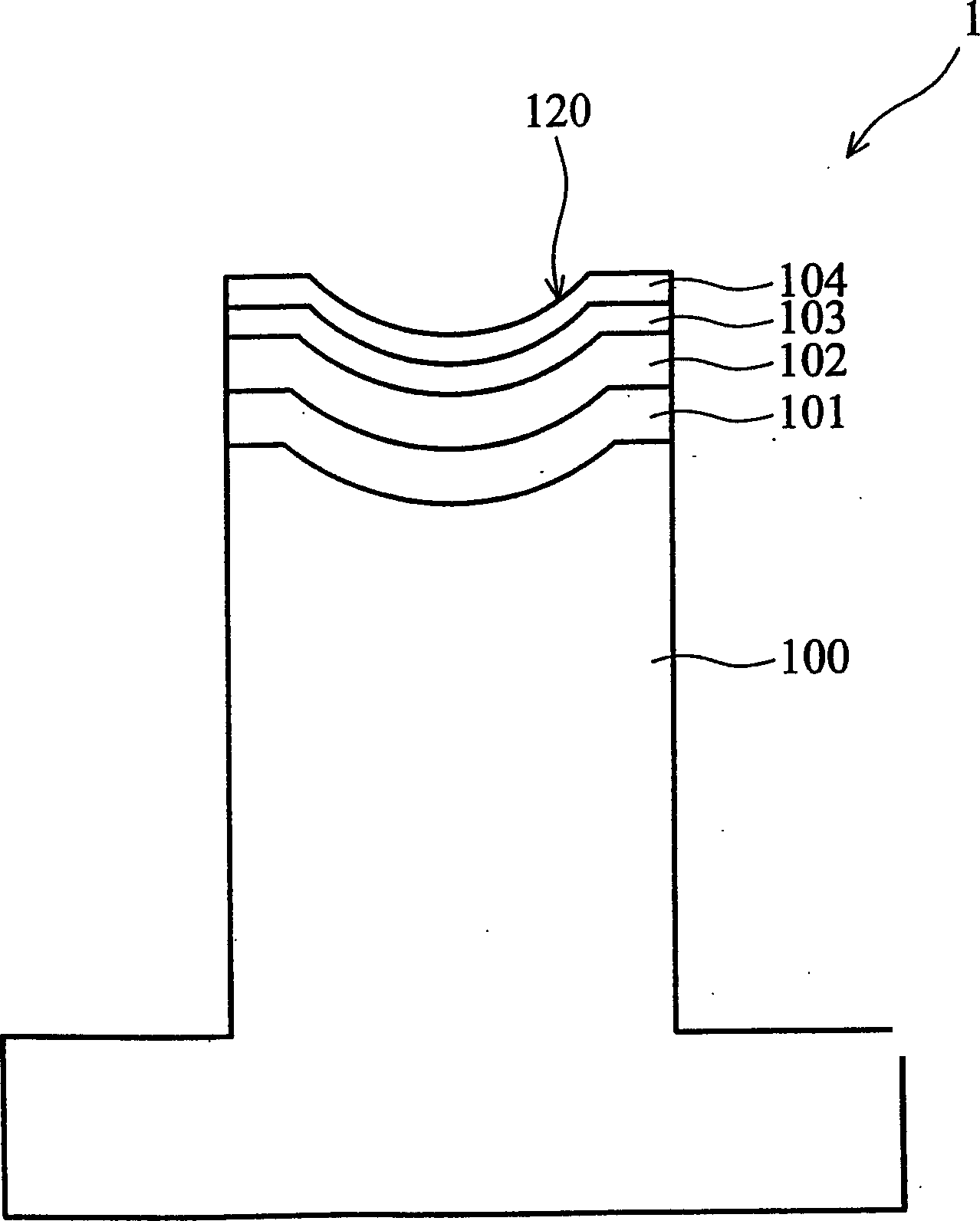

[0021] Please refer to figure 1 , is a cross-sectional view showing the structure of the mold core 1 for molding glass of the present invention. Wherein, the structure of the mold core 1 includes a substrate 100 , a first noble metal layer 101 , a second noble metal layer 102 , a third noble metal layer 103 , and a protective film 104 stacked in sequence. Wherein the protection film 104 is diamond-like carbon (DLC). In addition, the protective film 104 has a molding surface 120 thereon.

[0022] The substrate 100 is usually made of tungsten carbide, which usually contains a nickel component. Therefore, the material of the first noble metal layer 101 is preferably an iridium-rhenium alloy containing nickel to increase the distance between the first noble metal layer 101 and the substrate 100. Adhesion. In terms of the formation of the first noble metal layer 101, the surface of the substrate 100 is ground and polished first, and a layer of nickel-containing iridium-rhenium a...

Embodiment 2

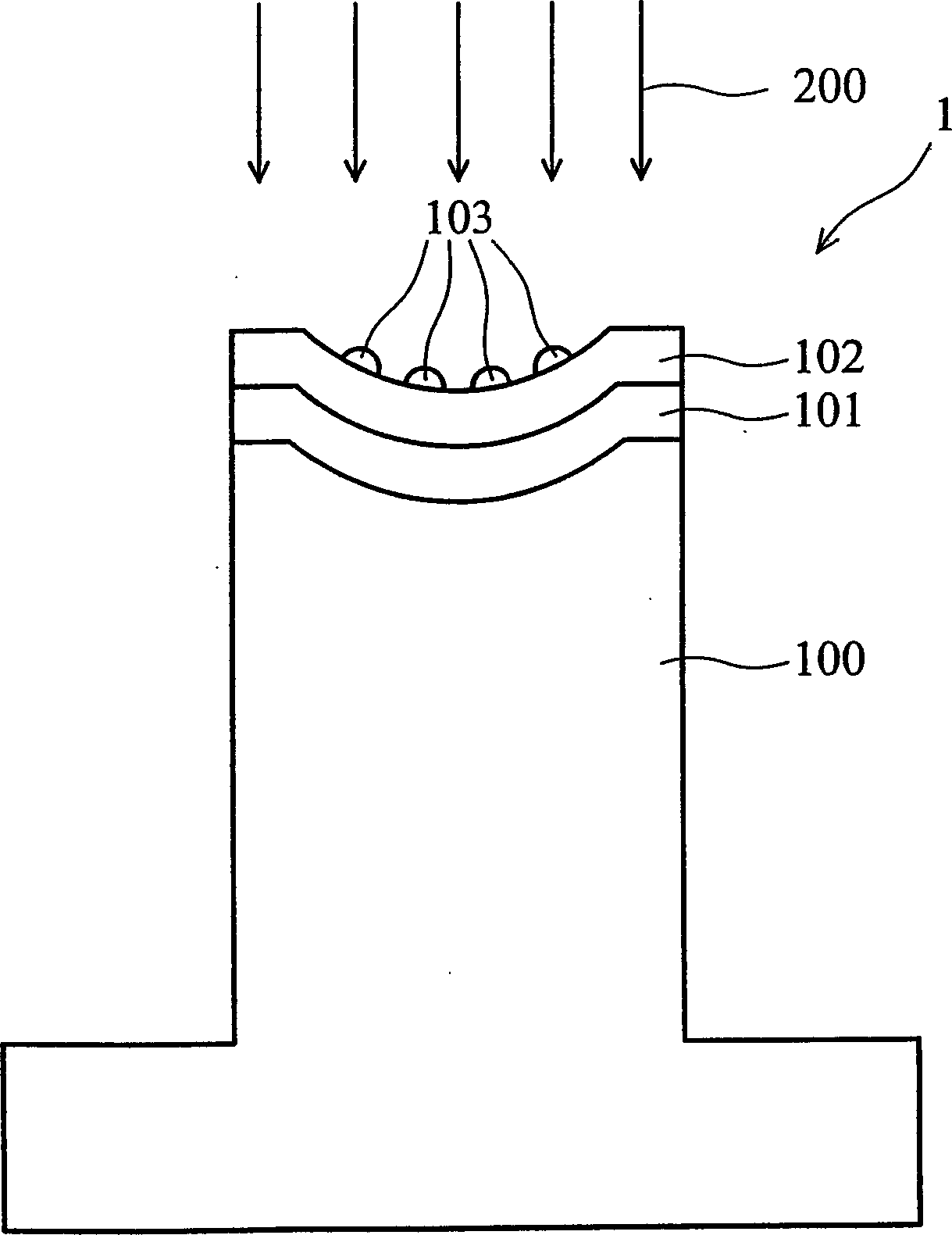

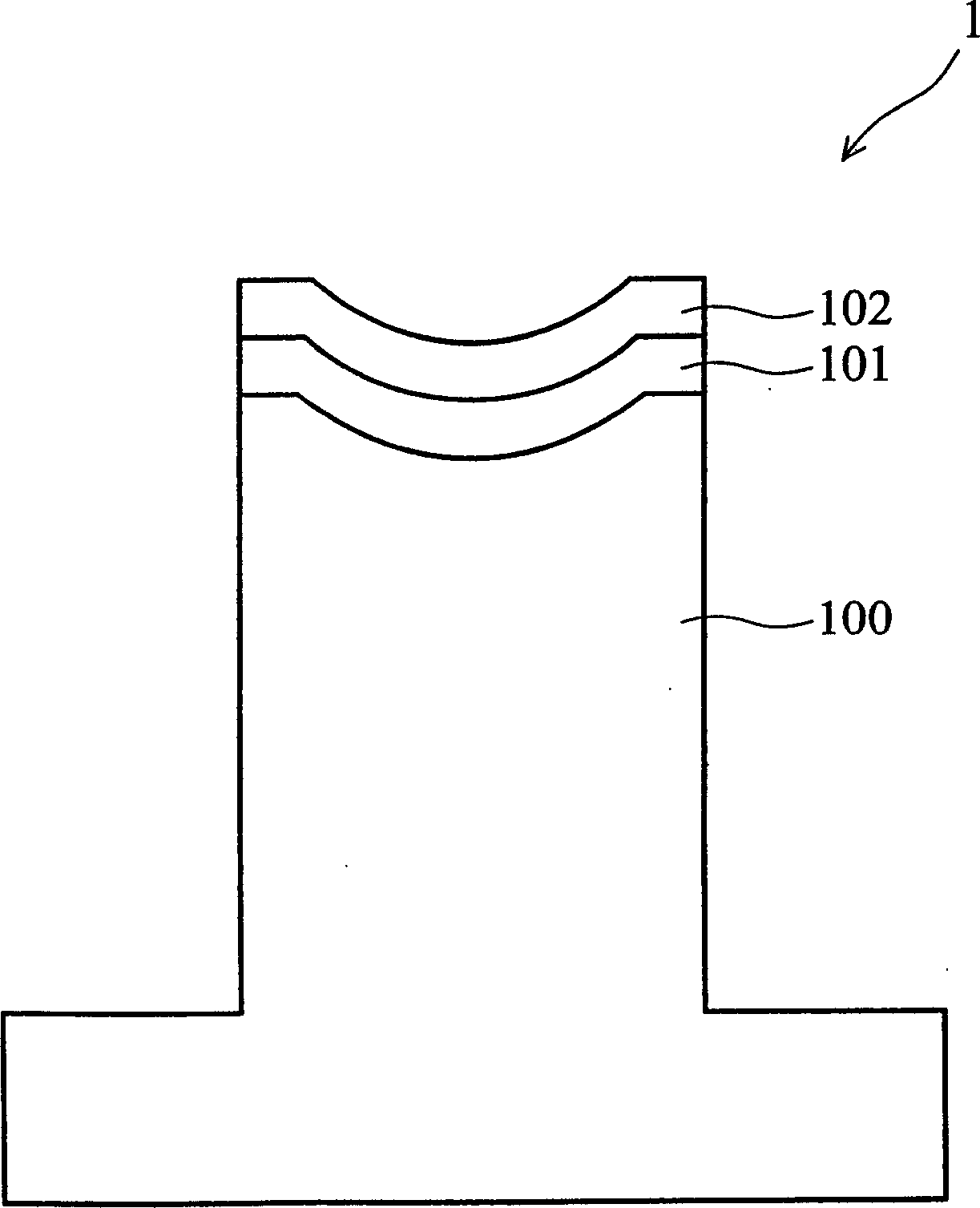

[0029] Please refer to Figures 2A-2C , is a series of cross-sectional views showing the flow of the method for regenerating the mold core 1 for glass molding according to the present invention.

[0030] because figure 1 The carbon in the protective film 104 and the third noble metal layer 103 of the mold core 1 of the molded glass of the present invention shown can be etched and removed by oxygen plasma. Therefore, when the use of the mold core 1 is about to expire or reaches its molding life, it will be replaced from the production line for regeneration. First, in Figure 2A In the process, oxygen plasma 200 is used to etch and remove the protective film 104 and the third noble metal layer 103, wherein, whether the third noble metal layer 103 is a noble metal layer with carbon atoms and noble metal atoms arranged in a superlattice, or a carburized surface , when the carbon atoms are etched and removed by the oxygen plasma 200, the remaining noble metal atoms will loosen o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com