Less-glossy easy-to-machine thermoplastic resin composition and its extruding processing method

A technology of thermoplastic resin and resin composition, which is applied in the field of ABS-PVC alloy resin composition, and can solve the problems of rising time and cost

Inactive Publication Date: 2005-09-28

PETROCHINA CO LTD

View PDF10 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the disadvantage of this is obvious. It not only puts forward strict requirements for heating control on the blending equipment, but also takes a considerable amount of time to complete the heating and cooling, which greatly increases the time and cost of the entire processing and production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0039] The performance of the ABS / PVC alloy material prepared by adopting the processing technology and formula described in the present invention is very superior, and the specific comparison results are shown in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

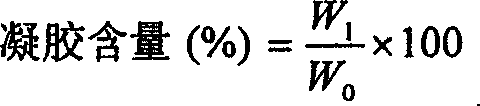

The present invention is less-glossy easy-to-machine thermoplastic resin composition and its extruding processing method. The thermoplastic resin composition is the mixture of PVC 10-80 weight portions, ABS resin 0-88 weight portions, ABS grafted copolymer 1-35 weight portions, styrene-acrylonitrile-ethylene copolymer 0-55 weight portions, acrylonitrile gel 1-10 weight portions and fluoroelastomer as machining assistant 0-5 weight portions, and has total rubber content of 5-30 wt%. The thermoplastic resin composition has excellent extruding formation performance, oil resistance and antishock performance as well as high rigidity, heat resistance, weather resistance, fireproof performance and economic performance.

Description

technical field [0001] The invention relates to a low-gloss easy-to-process thermoplastic resin composition and an extrusion processing method, in particular to an ABS-PVC alloy resin composition, which can be used in related fields such as sealing strips, pipes, plates, and flame-retardant shells. Background technique [0002] Due to the superior overall performance of low-gloss thermoplastic polymers, especially ABS / PVC alloy materials, there are many units engaged in research in this area, and there are many public reports. Disclose a kind of PVC / ABS alloy material of low ABS content as CN1191232A, adopt the ABS resin of high rubber phase (butadiene) content to modify PVC resin; Its manufacturing method; there are also flame-retardant grade ABS / PVC injection molding alloy (publication number is CN 1107487A) and the like. The characteristic of this type of technology is that the production and processing technology is relatively complicated. Either the stabilizer, additiv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C48/395C08L27/06C08L33/20

Inventor 谈敦礼赵振兴李社青谷育生王美玲

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com