Anti-cancer compound preparation of giant knotweed, Tengli root and thinleaf adina root and its making method and use

A technology of compound Polygonum cuspidatum and Polygonum cuspidatum root, which is applied in the direction of antineoplastic drugs, pharmaceutical formulas, medical preparations containing active ingredients, etc., can solve the problems of separation methods and preparation technologies that have not been reported, and achieve improved bioavailability and improved Transfer rate, the effect of facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

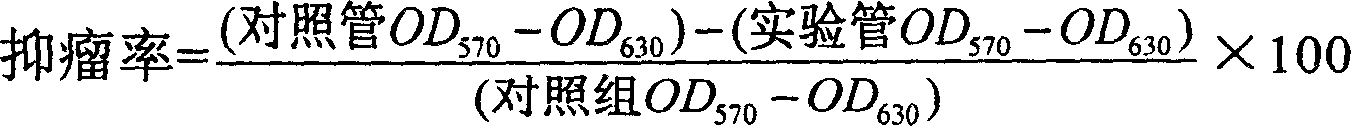

Method used

Image

Examples

Embodiment 1

[0027] 2Kg of Polygonum cuspidatum root, 1Kg of Tengli root, and 1Kg of Myrica rubra root are crushed into coarse powder, added with 40L of boiling water at 100°C, and timed for 90 minutes of leaching, during which time heating is maintained to maintain a slight boiling state. Filter, add 20L of boiling water at 100°C to the filter residue, and time leaching for 60 minutes, keep heating during the period, and maintain a slight boiling state. Filter, discard the filter residue, combine the filtrate twice, concentrate the filtrate to a thermal specific gravity of 1.05 under normal pressure, add 4 g of flocculant chitin, centrifuge after stirring (3000 rpm, 10 minutes), keep the supernatant, and adjust it with 10% HCl. pH to 2, stand still, centrifuge to remove precipitation (same conditions as above), the supernatant passes through the macroporous resin HPD100, and the active ingredients of the adsorbed medicinal materials are eluted with 70% ethanol aqueous solution, and the elu...

Embodiment 2

[0029]5Kg of Polygonum cuspidatum root, 1Kg of Tengli root, and 1Kg of Myrica rubra root are crushed into coarse powder, added with 84L of boiling water at 100°C, and timed for 120 minutes of leaching, during which time heating is maintained to maintain a slightly boiling state. Centrifuge (3000 rpm, 10 minutes), add 41L of 100°C boiling water to the filter residue, and time leaching for 120 minutes, during which heating is maintained to maintain a slightly boiling state. Centrifuge (3000 rpm, 15 minutes), discard the filter residue, combine the centrifuged liquid twice, add flocculant gelatin 70g, filter after stirring, adjust the pH of the filtrate to 5 with 5% HCl, let it stand, filter to remove the precipitate, supernatant The liquid passes through the macroporous resin HPD300, and the active ingredients of the adsorbed medicinal materials are eluted with 80% acetone aqueous solution. The eluent is decompressed to recover ethanol, the vacuum degree is greater than 0.04Mpa, ...

Embodiment 3

[0031] 3Kg of Polygonum cuspidatum root, 2Kg of Tengli root, and 1Kg of Myrica rubra root were crushed into coarse powder, added with 48L of boiling water at 100°C, and leached for 60 minutes at a time, during which heating was maintained to maintain a slight boiling state. Filter, add 24L of boiling water at 100°C to the filter residue, and time leaching for 60 minutes, keep heating during the period, and maintain a slightly boiling state. Filter, add 24L of boiling water at 100°C to the filter residue, and time leaching for 60 minutes, keep heating during the period, and maintain a slightly boiling state. Filter, discard the filter residue, merge the filtrate three times, the filtrate is concentrated under reduced pressure to thermal specific gravity 1.05 (vacuum tightness is greater than 0.04Mpa), adds ZTC flocculant 30g produced by Tianjin Zhengtiancheng Clarification Technology Co., Ltd., centrifuges after stirring (3000 rpm , 10 minutes), retain the supernatant, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com