Extraction, purification and conversion of flavonoids from plant biomass

A compound, flavonoid technology, applied in the field of extraction, purification and conversion of flavonoids from plant biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

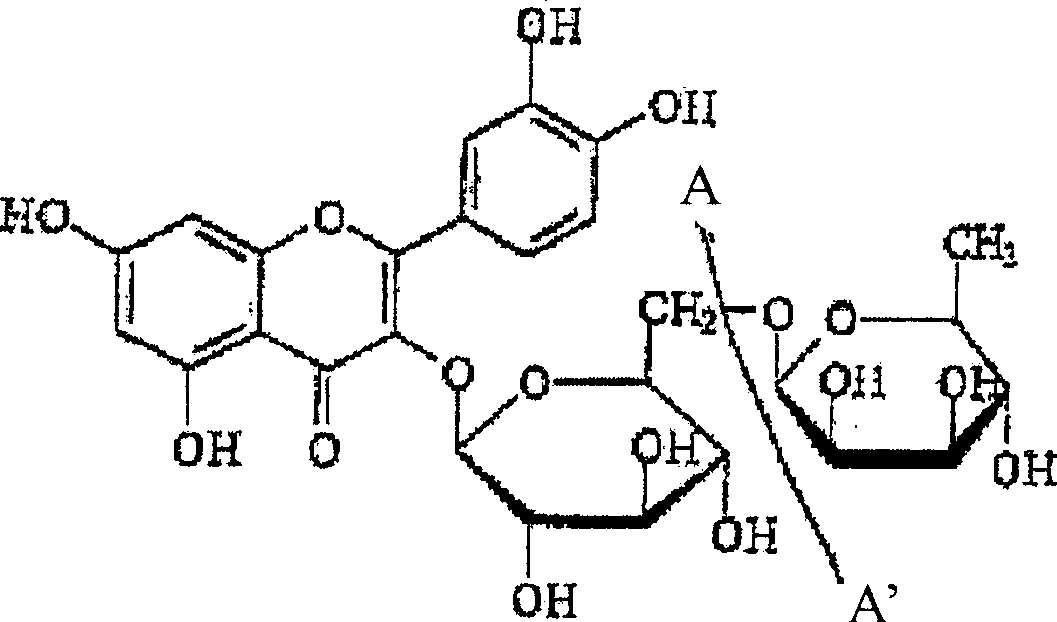

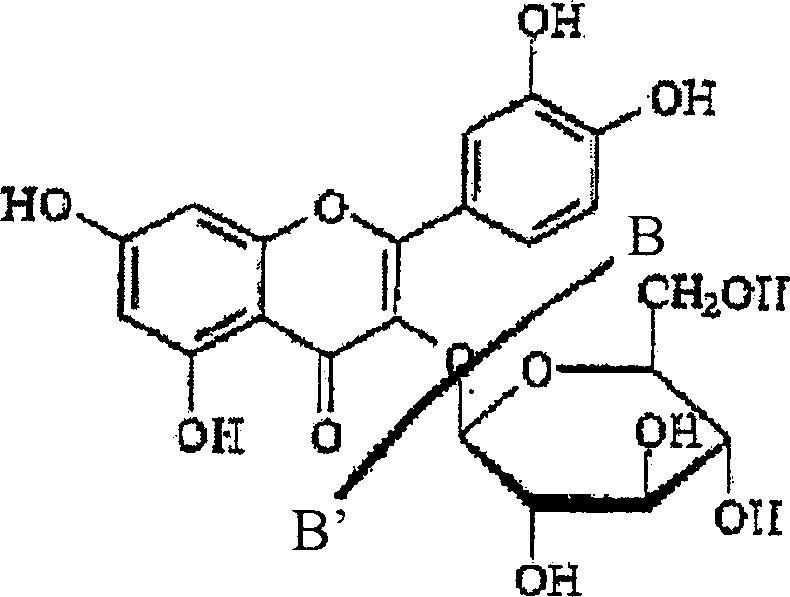

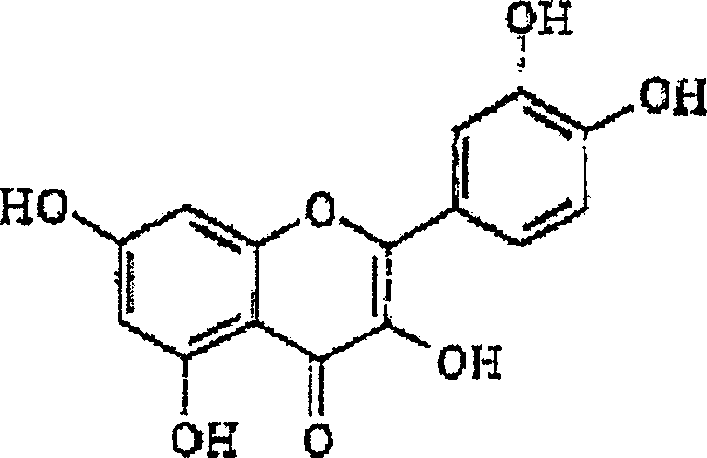

Image

Examples

Embodiment 1

[0137] Example 1: Aqueous extraction, concentration and precipitation of rutin from buckwheat leaf material

[0138] After harvesting and drying, buckwheat leaves were ground on a Wiley mill to pass through a 2mm sieve, thereby preparing buckwheat leaves for extraction. Extraction was carried out by 1 kg of ground buckwheat leaves (3.74% rutin content, based on dry weight) in 10 L of water with continuous stirring at 90° C. for 1 hour. The resulting suspension was filtered, and the filter cake was washed twice with 300 ml of hot (95° C.) water. The washed filtrate was mixed with the extract to obtain a combined extract with a volume of 8.6 L. This aqueous extraction method recovered 36% of the available rutin from the leaves.

[0139] The extract was concentrated under reduced pressure to about 1 / 5 and 1 / 10 of its original volume. The concentrated extract was stored in the refrigerator (4°C) overnight, at which time the flavonoid compounds precipitated out of solution. The...

Embodiment 2

[0140] Example 2: Aqueous Alcoholic Extraction, Concentration and Precipitation of Rutin from Buckwheat Leaf Material

[0141] After harvesting and drying, buckwheat leaves were ground on a Wiley mill to pass through a 2mm sieve, thereby preparing buckwheat leaves for extraction. 1 kg of ground buckwheat leaves (rutin content 3.74%, based on dry weight) were extracted in 10 L of 50% (v / v) aqueous methanol, specifically with continuous stirring at 40° C. for 3 hours. The resulting suspension was filtered, and the filter cake was washed with warm (40%) 50% (v / v) aqueous methanol. The washed filtrate was combined with the extract. This extraction method recovered 65% of the available rutin from the leaves. Figure 2A illustrates the concentration of rutin in methanolic extracts. The extract was concentrated to about 1 / 5 of its original volume under reduced pressure. The concentrated extract was stored in the refrigerator (4°C) overnight, at which time the flavonoid compounds p...

Embodiment 3

[0142] Example 3: Purification of rutin from a flavonoid-rich intermediate isolated from buckwheat leaves

[0143] The rutin-enriched product from Example 2 was dissolved in warm methanol with vigorous stirring on a magnetic stirrer to promote complete dissolution of the rutin. Any insoluble material was removed from the solution using vacuum filtration. The solution was evaporated to dryness at 40°C under reduced pressure. The residue was then suspended in hot (90°C) water with continuous stirring until most of the precipitate had dissolved. Allow the suspension to settle overnight in the refrigerator. The precipitate was removed by vacuum filtration and freeze-dried. The purified rutin precipitate was dissolved in methanol, filtered through a 0.45 μm nylon syringe filter, and analyzed by RP-HPLC to confirm product purity. After repeated dissolution / crystallization without chromatography, the rutin content increased to about 70% and higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com