Purification production technique for producing high pure and high clear lithium hydroxide from lithium hydroxide in industrial grade

A technology of lithium hydroxide and production technology, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problem that high-purity high-definition lithium hydroxide cannot be produced industrially, and achieve high product yield, simplified process and shortened operation. Convenient and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

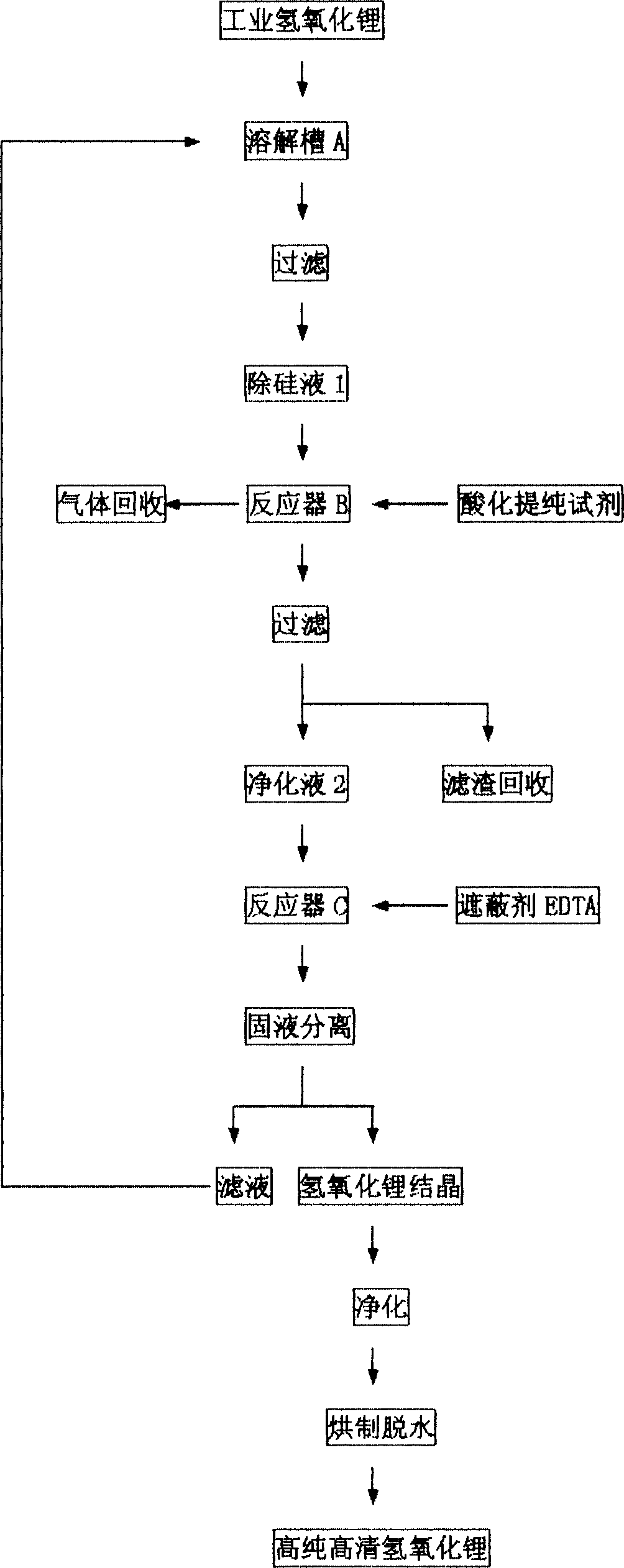

[0025] see as figure 1 As shown in, the purification production technology of producing high-purity and high-definition lithium hydroxide from industrial-grade lithium hydroxide of the present invention, the raw materials are produced by Xinjiang Lithium Salt Factory, and the industrial grade 1 quality standard. Its main quality indicators are: LiOH·H 2 O main content: ≥56.5 (molecular crystallization water is counted), the content of each impurity element is as follows: CO 2 : 0.5%, K + : 0.15%, Na + : 0.05%, CaO: 0.035%, Fe 2+ : 0.003%, Cl - : 0.004%, SO 4 2- : 0.03%, hydrochloric acid insoluble matter: 0.01%, water insoluble matter: 0.02%. The impurity content of silicon (Si) in the raw material is mainly expressed in the form of hydrochloric acid insoluble matter and water insoluble matter, the sum of which is 0.03%, ie 300ppm. Feed about 170kg of industrial-grade lithium hydroxide, add about 650kg of conductive water, introduce it into the dissolution tank A, stir...

Embodiment 2

[0027] Use the same raw materials as in Example 1, feed about 170kg of industrial grade lithium hydroxide, add about 650kg of conductive water, introduce it into the dissolution tank A, stir at room temperature 30°C for 10 minutes to fully dissolve, and remove surface impurities after standing for 10 minutes , and then quickly filtered to remove about 0.1 to 0.2% of the total weight of insoluble sediment to obtain silicon removal solution 1, inject silicon removal solution 1 into reactor B and start heating, when the temperature reaches 50°C, add 7% carbonation Reagents were purified and subjected to partial carbonation co-precipitation reactions. Ammonia and hydrogen are released during the reaction, which should be discharged and recovered in time with ventilation equipment. Continue heating to boiling (about 100-105°C), and keep boiling for 1 hour, so that all kinds of reactions can be carried out completely. Filtrate while hot within 20 minutes after stopping heating, carr...

Embodiment 3

[0029] Use the same raw materials as in Example 1, feed about 170kg of industrial grade lithium hydroxide, add about 650kg of conductive water, introduce it into the dissolution tank A, stir at room temperature 25°C for 15 minutes to fully dissolve, and remove surface impurities after standing for 8 minutes , and then quickly filtered to remove about 0.1 to 0.2% of the total weight of insoluble sediment to obtain silicon removal solution 1, inject silicon removal solution 1 into reactor B and start heating, when the temperature reaches 45°C, add 4% carbonation Reagents were purified and subjected to partial carbonation co-precipitation reactions. Ammonia and hydrogen are released during the reaction, which should be discharged and recovered in time with ventilation equipment, continue to heat to boiling (about 100-105°C), and keep boiling for 50 minutes to complete the various reactions. Filtrate while hot within 15 minutes after stopping the heating, and separate the liquid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com