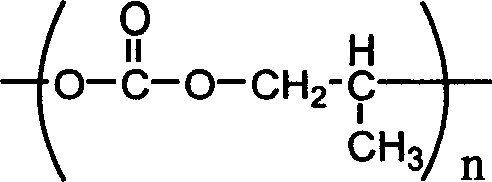

Composite material of complete degradable polymer and preparation method thereof

A composite material and polymer technology, applied in the field of polymethylethylene carbonate/polyvinyl alcohol composite material and its preparation, can solve the problems of limited application range, poor mechanical properties, low glass transition temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0016] The composition and properties of the composite materials are shown in Table 1. Polymethylethylene carbonate and 1588 polyvinyl alcohol were dissolved in dimethyl sulfoxide at 60° C., with a total concentration of 5-10% (w / v). Stir mechanically for 12-16 hours, pour the solution on a glass plate covered with PET film, and dry the solvent in a 60°C ordinary oven and a 120°C vacuum oven. The obtained composite film was cut into vertical strips of 75×5 mm for mechanical and thermal performance tests.

[0017] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com