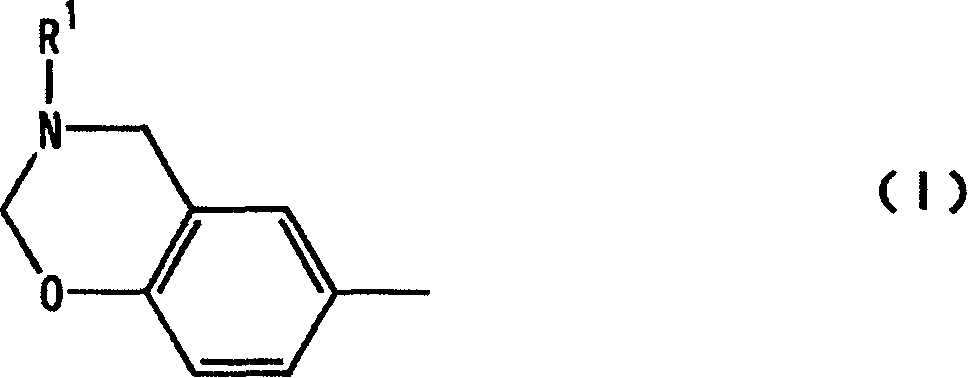

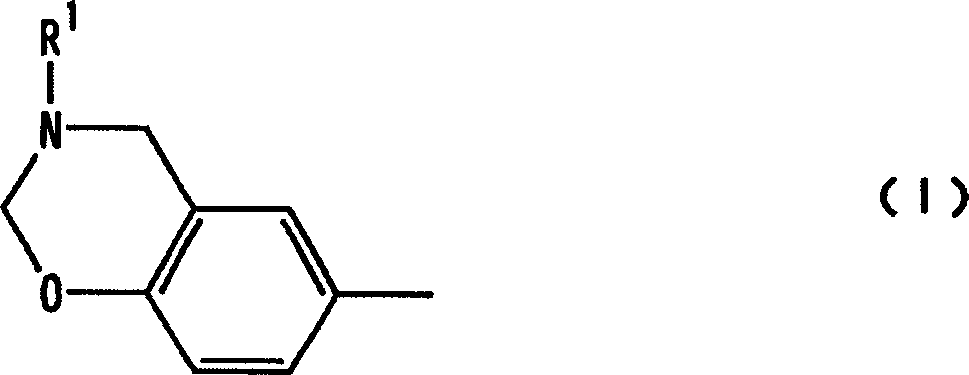

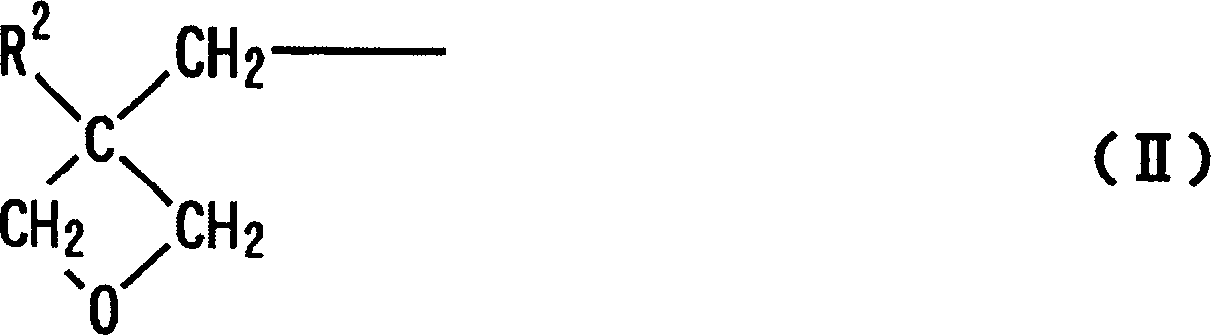

Thermoset resin composition and multi-layer printed circuit board used thereof

A resin composition, thermosetting technology, applied in printed circuit parts, secondary processing of printed circuits, epoxy resin coatings, etc., can solve problems such as large strain, reduce elastic coefficient, prevent interlayer peeling, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2 and comparative example 1、2

[0051] After pre-mixing the additive components shown in the following Table 1, they were ground and dispersed with a 3-roll kneader to obtain each thermosetting resin composition.

[0052] Example

comparative example

1

2

1

2

Bisphenol A type epoxy resin *1

42.5

80.0

50

45

Bisphenol F type epoxy resin *2

42.5

-

50

45

polyfunctional phenolic compound *3

15

15.0

60

10

Oxetane compounds *4

10

5.0

-

-

Compounds containing oxetane rings *5

-

10.0

-

-

curing catalyst *6

5.0

5.0

2.0

5.4

Organic solvents *7

-

-

-

7.0

spherical silica

90.0

90.0

90.0

90.0

30.0

30.0

30.0

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com