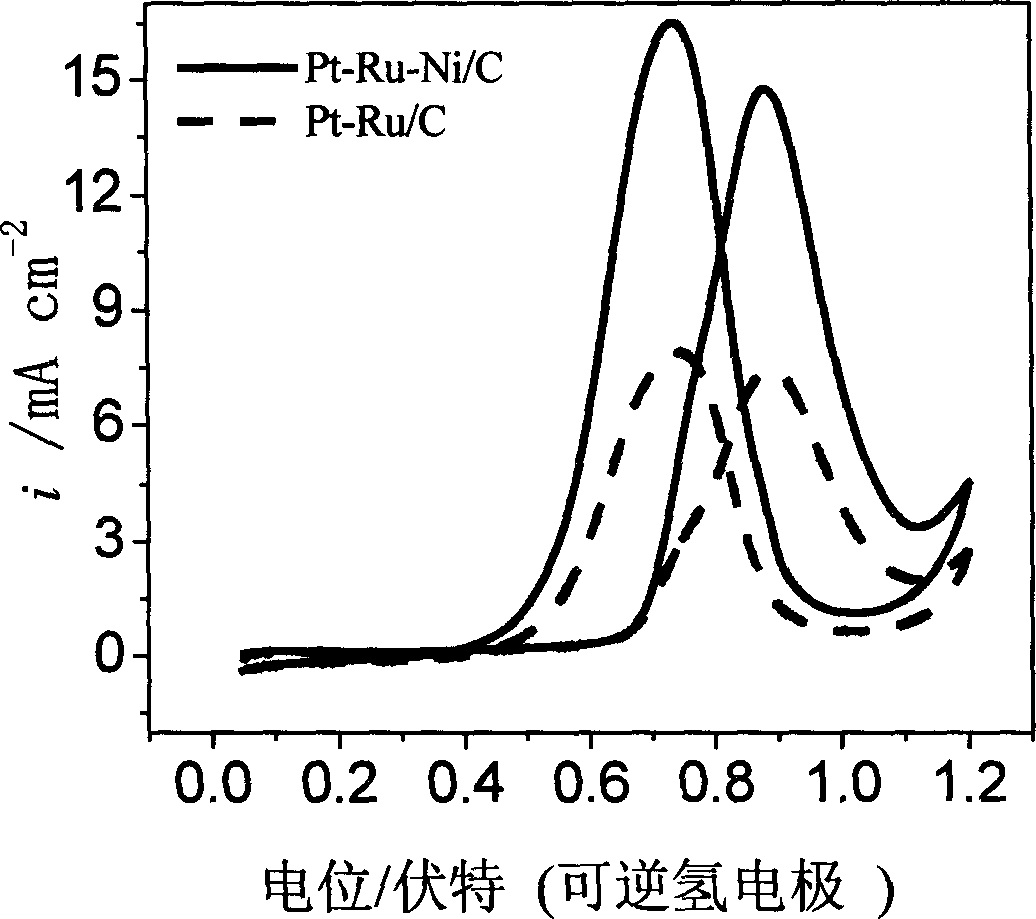

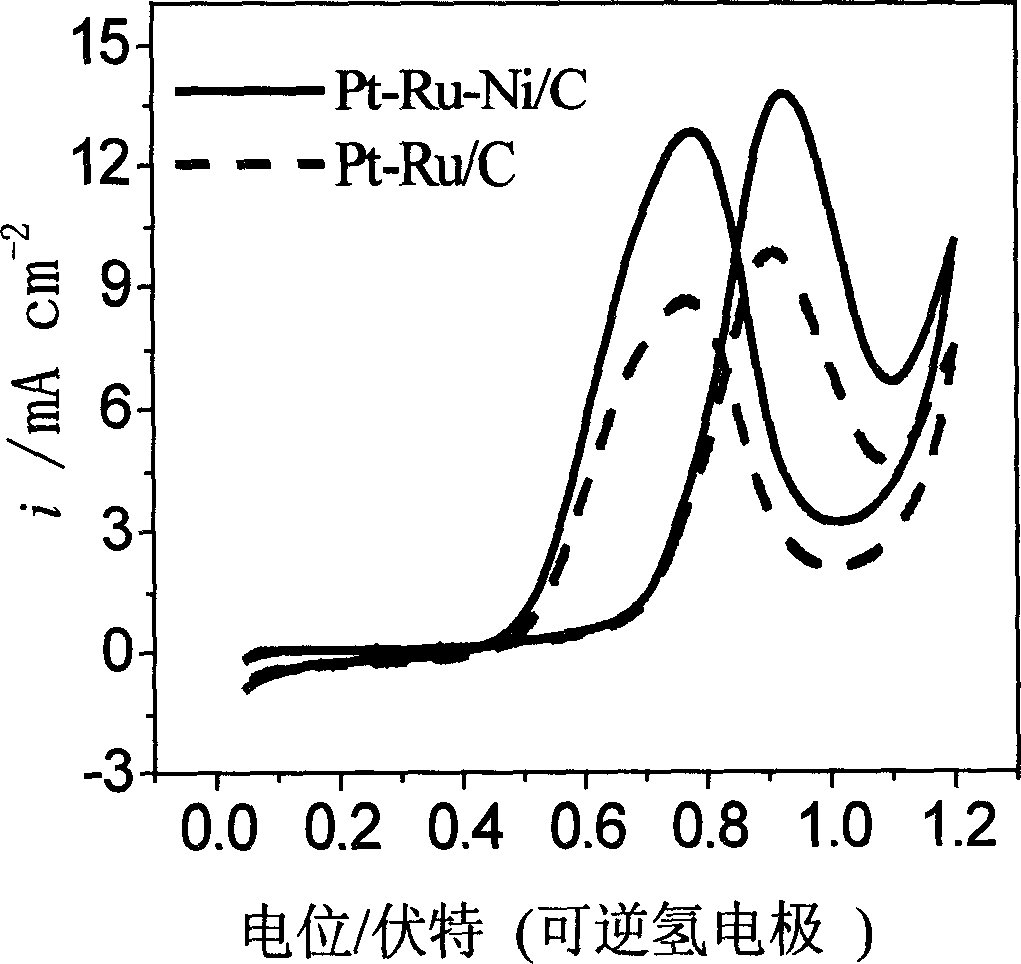

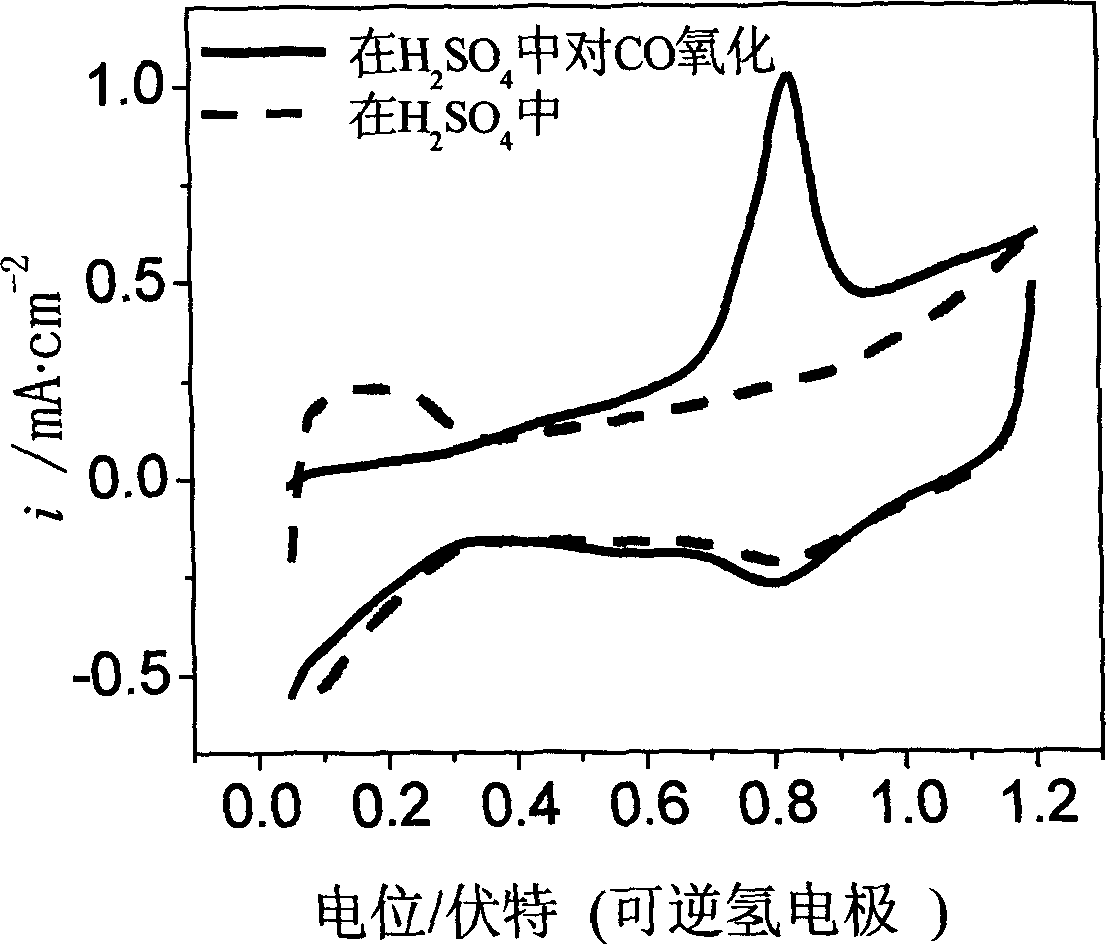

Method for preparing Pt-Ru-NI/C catalyst in use for fuel cell of direct alcohols

A fuel cell and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of expensive battery catalysts and limited resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific Embodiment 1: This embodiment is achieved through the following steps: 1. Add the carbon carrier that has undergone hydrophilic treatment into the mixed solution of deionized water and isopropanol, disperse evenly, and make a carbon-containing slurry; 2. Put the Pt , Ru and Ni compound precursors are added to the uniformly dispersed carbon-containing slurry, so that the Pt, Ru and Ni compound precursors are evenly dispersed on the carbon carrier; 3. The uniformly dispersed carbon-supported Pt, Ru and Ni compound precursor slurry Adjust the pH value to 3-10; 4. Heat the obtained slurry to 50-90°C, add a reducing agent, and reduce for 1-5 hours to form a reducing solution; 5. Rinse the reducing solution with ultra-pure water, It can be dried under vacuum condition at ℃ for 1-6 hours (that is, the Pt-Ru-Ni / C three-way catalyst is prepared). The metal molar ratio of Pt, Ru and Ni is 4-7:2-5:1-3. The reducing agent is sodium borohydride or potassium borohydride. T...

specific Embodiment approach 2

[0006] Embodiment 2: In step 3 described in this embodiment, the pH value is adjusted to 6-8. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Embodiment 3: The temperature of the slurry in step 4 described in this embodiment is 60-90°C. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com