Preparation method of three-dimensional honeycomb CuInS2 nanowire array solar absorbing material

A nanowire array and solar energy absorption technology, which is applied in the field of solar energy applications, can solve the problems of limited application space, difficulty comparable to array structures, and inability to obtain two-dimensional layered structures, etc., to achieve good light harvesting ability, improved band gap, and uniformity good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A three-dimensional honeycomb CuInS 2 A method for preparing a nanowire array solar energy absorbing material, comprising the following steps:

[0030] (1) Mix indium chloride and thioacetamide at a molar ratio of 1:1 and add them to a polytetrafluoroethylene reactor, then add ethylene glycol to make a solution with an indium salt concentration of 0.5M, stir or ultrasonically dissolve ;

[0031] (2) placing the copper substrate for growing cuprous sulfide nanowire arrays in the reaction kettle;

[0032] (3) Seal the reactor, control the temperature at 200°C, and react for 4 hours; after the reaction, the reactor is naturally cooled to room temperature to obtain a three-dimensional honeycomb CuInS 2 The nanowire array film is uniformly grown on the surface of the copper substrate.

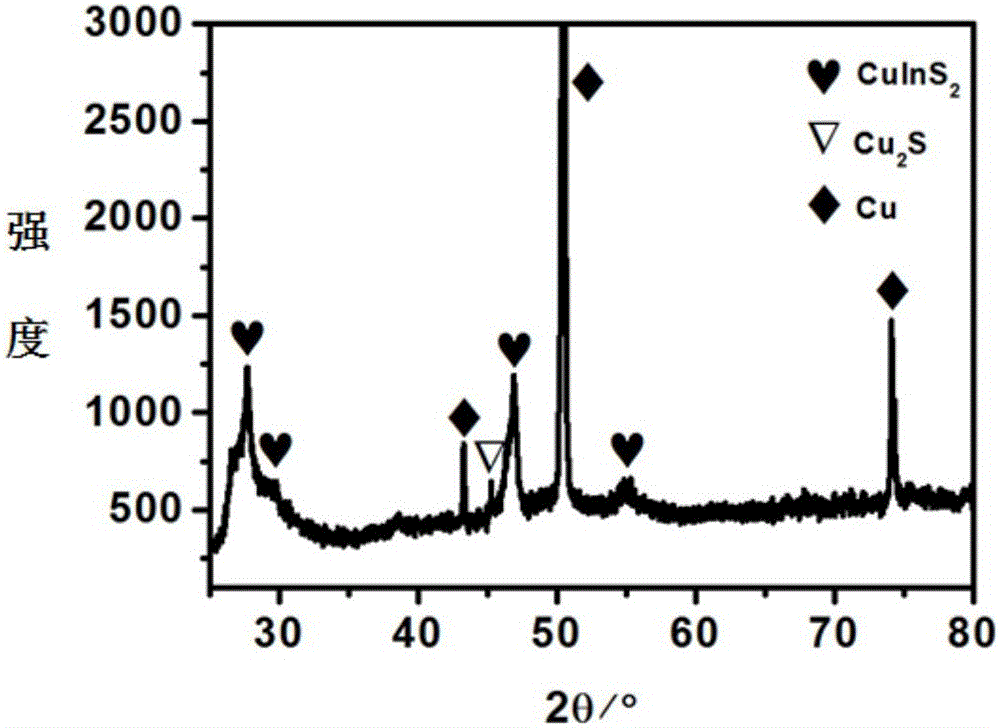

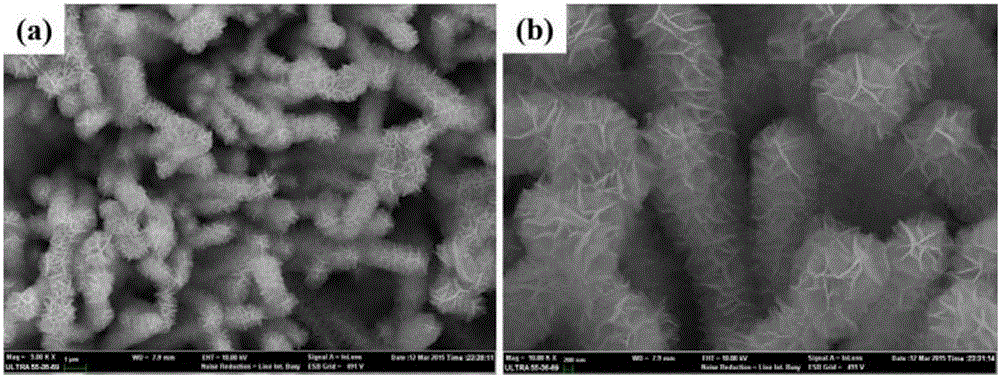

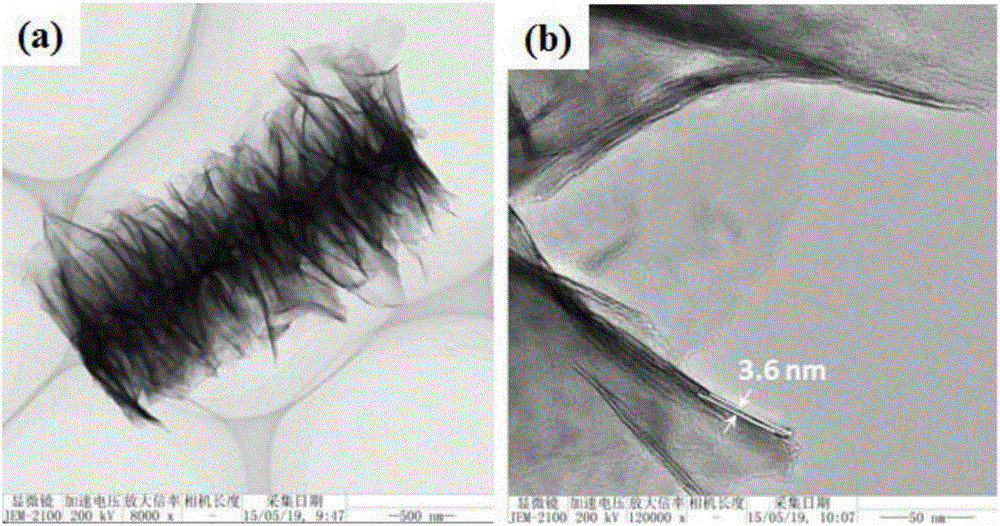

[0033] figure 1 For the CuInS obtained in this embodiment 2 XRD pattern of the film; by figure 1 It can be seen that, except for the peak of copper substrate, almost all peaks correspon...

Embodiment 2

[0037] A three-dimensional honeycomb CuInS 2 A method for preparing a nanowire array solar energy absorbing material, comprising the following steps:

[0038] (1) Mix indium acetate and thiourea at a molar ratio of 1:5 and add them to a polytetrafluoroethylene reactor, then add ethylene glycol to form a solution with an indium salt concentration of 0.2M, stir or ultrasonically dissolve;

[0039] (2) Place the bottom of the copper sheet growing the cuprous oxide nanowire array in the above-mentioned reaction kettle;

[0040] (3) Seal the reactor, control the temperature at 180°C, and react for 7 hours; after the reaction, the reactor is naturally cooled to room temperature to obtain a three-dimensional honeycomb CuInS 2 The nanowire array film is uniformly grown on the surface of the copper substrate.

Embodiment 3

[0042] A three-dimensional honeycomb CuInS 2 A method for preparing a nanowire array solar energy absorbing material, comprising the following steps:

[0043] (1) Indium acetylacetonate and sulfur powder are mixed and added to a polytetrafluoroethylene reactor at a molar ratio of 1:10, and then ethanol is added to form a solution with an indium salt concentration of 0.2M, which is stirred or ultrasonically dissolved;

[0044] (2) placing the conductive glass substrate for growing copper sulfide nanowire arrays in the reaction kettle;

[0045] (3) Seal the reactor, control the temperature at 160°C, and react for 10 hours; after the reaction, the reactor is naturally cooled to room temperature to obtain a three-dimensional honeycomb CuInS 2 The nanowire array thin film grows uniformly on the substrate surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com