Preparation method of single crystal indium nanowire and its products and applications

A crystalline indium nanometer and indium nanometer technology, which is applied in the field of nanomaterial preparation, can solve the problems of complex process, poor quality of indium nanowires and high cost, and achieve the effects of simple preparation process, good repeatability and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing single crystal indium nanowires, comprising the following steps:

[0030] (1) First polish the cut zinc sheet with 3000 mesh sandpaper to remove the oxide layer on the surface; then wash it with acetone, absolute ethanol, and deionized water for 10 minutes, dry it with an air gun, and then put it into the reaction substrate as a base in the tank;

[0031] (2) Mix thioacetamide and indium chloride into the reaction kettle according to the molar ratio of 4:2, then add ethylene glycol, and then stir or ultrasonically dissolve to form a uniform solution with an indium salt concentration of 0.2M ;

[0032] (3) Seal the reactor, control the temperature at 200°C, and react for 30 minutes; after the reaction, the reactor is naturally cooled to room temperature, and the samples are taken out and washed and dried to obtain single crystal indium nanowires grown uniformly on the zinc sheet.

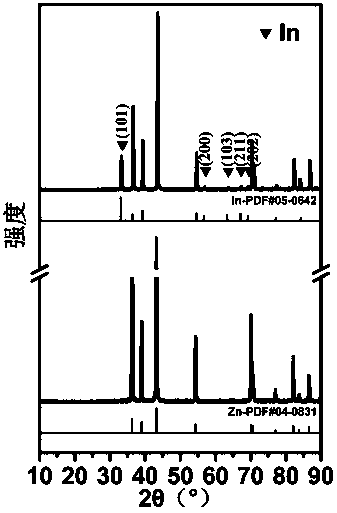

[0033] figure 1 It is the XRD pattern of the single crystal indi...

Embodiment 2

[0036] A method for preparing single crystal indium nanowires, comprising the following steps:

[0037] (1) First polish the cut zinc sheet with 3000 mesh sandpaper to remove the oxide layer on the surface; then wash it with acetone, absolute ethanol, and deionized water for 10 minutes, dry it with an air gun, and then put it into the reaction substrate as a base in the tank;

[0038] (2) Mix thiourea and indium chloride into the reaction kettle according to the molar ratio of 2:2, then add ethylene glycol, and then stir or ultrasonically dissolve to form a uniform solution with an indium salt concentration of 0.4M;

[0039] (3) Seal the reactor, control the temperature at 160°C, and react for 40 minutes; after the reaction, the reactor is naturally cooled to room temperature, and the samples are taken out and washed and dried to obtain single crystal indium nanowires grown uniformly on the zinc sheet.

Embodiment 3

[0041] A method for preparing single crystal indium nanowires, comprising the following steps:

[0042] (1) First polish the cut zinc sheet with 3000 mesh sandpaper to remove the oxide layer on the surface; then wash it with acetone, absolute ethanol, and deionized water for 10 minutes, dry it with an air gun, and then put it into the reaction substrate as a base in the tank;

[0043] (2) Mix thioacetamide and indium acetate into the reaction kettle according to the molar ratio of 6:2, then add ethylene glycol, and then stir or ultrasonically dissolve to form a uniform solution with an indium salt concentration of 0.6M;

[0044](3) Seal the reactor, control the temperature at 220°C, and react for 20 minutes; after the reaction, the reactor is naturally cooled to room temperature, and the samples are taken out and washed and dried to obtain single crystal indium nanowires grown uniformly on the zinc sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com